Cleaning method of phosphorous gypsum conveying-pipe-shaped belt

A technology for tubular belts and phosphogypsum, applied in cleaning methods and tools, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problem that acidic materials cannot be cleaned up, and avoid scratches on tubular belts and maintenance cycles Long-term and safe operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is only used to explain the present invention and does not constitute a limitation to the protection scope of the present invention.

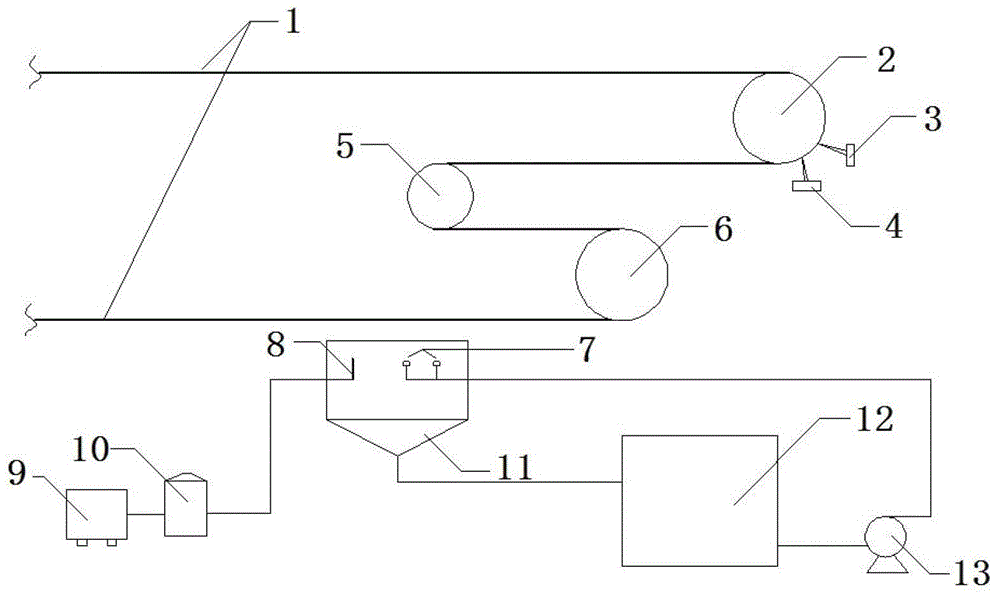

[0017] The tube belt machine is driven by two 800KW motors at the head and two 800KW motors at the tail. The material is fed from the tail of the tube belt machine and transported to the head of the tube belt machine through the tubular belt 1 for unloading. At the head drive drum 1 and 2 of the pipe belt machine, after the tubular belt 1 is cleaned by the first-level scraper cleaner 3 and the second-level scraper cleaner 4, it passes through the reversing drum 5 and the drive drum 2 A cleaning device is installed under the tubular belt 1 in the transition section at the top. There are two rows of high-pressure water cleaning n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com