An industrial circulating water treatment agent

An industrial circulating water and chemical treatment technology, applied in water/sludge/sewage treatment, special treatment targets, water softening, etc., can solve problems such as phosphorus pollution, achieve the elimination of oil pollution, reduce the speed of metal corrosion, and inhibit the anode The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

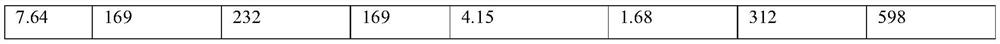

Embodiment 1

[0031]An industrial circulating water treatment agent, comprising the following raw materials in parts by mass: 1.2 parts of dodecyl dimethyl benzyl ammonium chloride, 29 parts of compound corrosion inhibitor, 21 parts of scale inhibitor, 5 parts of bactericide, 42 parts of water. The compound corrosion inhibitor includes the following raw materials in parts by mass: 25 parts of modified imidazoline, 10 parts of oxalazide compounds, 5 parts of sodium erythorbate, 7 parts of zinc sulfate and 10 parts of sodium D-gluconate; The agent includes the following raw materials in parts by mass: 9 parts of polyacrylic acid, 12 parts of tannic acid and 16 parts of acrylic copolymer; the bactericide includes the following raw materials in parts by mass: 7 parts of dithiocyanomethane and 10 parts of glutaraldehyde.

[0032] Modified imidazoline is prepared by the following steps in the present embodiment:

[0033] (1) Prepare raw materials: 1.4mol of lauric acid, 0.6mol of ricinoleic acid...

Embodiment 2

[0038] An industrial circulating water treatment agent, comprising the following raw materials in parts by mass: 1.5 parts of tetradecyl dimethyl benzyl ammonium chloride, 30 parts of compound corrosion inhibitor, 20 parts of scale inhibitor, 7 parts of bactericide, 45 parts of water. The compound corrosion inhibitor includes the following raw materials in parts by mass: 24 parts of modified imidazoline, 12 parts of oxalazide compounds, 4 parts of sodium erythorbate, 6 parts of zinc sulfate and 12 parts of sodium D-gluconate; The agent includes the following raw materials in parts by mass: 8 parts of polyacrylic acid, 10 parts of tannic acid and 15 parts of acrylic copolymer; the bactericide includes the following raw materials in parts by mass: 6 parts of dithiocyanomethane and 12 parts of glutaraldehyde.

[0039] Modified imidazoline is prepared by the following steps in the present embodiment:

[0040] (1) Prepare raw materials: 1.5mol of lauric acid, 0.8mol of ricinoleic ...

Embodiment 3

[0045] An industrial circulating water treatment agent, comprising the following raw materials in parts by mass: 1.8 parts of dodecyl dimethyl benzyl ammonium chloride, 30 parts of compound corrosion inhibitor, 21 parts of scale inhibitor, 8 parts of bactericide, 42 parts of water. The composite corrosion inhibitor includes the following raw materials in parts by mass: 25 parts of modified imidazoline, 10 parts of oxalazide compounds, 5 parts of sodium erythorbate, 6 parts of zinc molybdate and 10 parts of sodium D-gluconate; The scale agent includes the following raw materials in parts by mass: 10 parts of polyacrylic acid, 12 parts of tannic acid and 16 parts of acrylic copolymer; the bactericide includes the raw materials of the following parts by mass: 6 parts of dithiocyanomethane and 12 parts of glutaraldehyde .

[0046] Modified imidazoline is prepared by the following steps in the present embodiment:

[0047] (1) Prepare raw materials: lauric acid 1.5mol, ricinoleic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com