Industrialization production technology for extracting ginkgolic acid from Ginkgo testa

A technology of Ginkgo biloba seed coat and ginkgolic acid is applied in the separation/purification of carboxylic acid compounds, chemicals for biological control, organic chemistry, etc., and can solve the problems of complicated extraction process, inability to popularize and apply, and high operation requirements. , to achieve the effect of simple process, improved utilization value and good killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

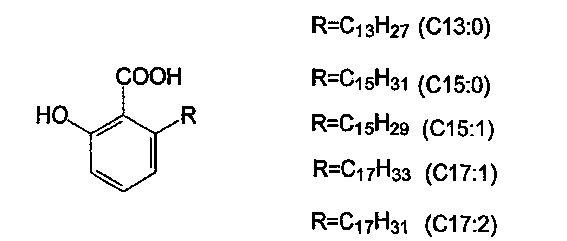

Image

Examples

Embodiment 1

[0028] A kind of industrialized production technology of extracting ginkgolic acid from the outer testa of ginkgo, is characterized in that comprising the following steps:

[0029] (1) Grind the washed ginkgo testa until fine, pass through 30 mesh, add water 5 times its weight, stir and soak for 5 hours;

[0030] (2) Centrifuge the soaked mixed solution to remove slag, pump the filtrate into the concentration pot, fractionate the components at 48°C under a vacuum of 0.08Mpa, and concentrate them;

[0031] (3) Add 10% hydrochloric acid to the concentrated solution to adjust the pH value to 3, cool to 10°C, brown crystals are precipitated, and 60% ginkgolic acid is obtained by suction filtration;

[0032] (4) After fully dissolving the brown crystals in step (3) with ethanol at 50°C, filter out the insoluble matter, cool to 20°C, precipitate light brown crystals, and filter to obtain 90% ginkgolic acid;

[0033] (5) Add the light brown crystals in step (4) to 5 times the weight...

Embodiment 2

[0035] A kind of industrialized production technology of extracting ginkgolic acid from the outer testa of ginkgo, is characterized in that comprising the following steps:

[0036] (1) Grind the washed ginkgo testa until fine, pass through 60 mesh, add water with 8 times the weight, stir and soak for 8 hours;

[0037] (2) Centrifuge the soaked mixed solution to remove slag, pump the filtrate into the concentration pot, fractionate the components at 60°C under a vacuum of 0.085Mpa, and concentrate them;

[0038] (3) Add 20% hydrochloric acid to the concentrated solution to adjust the pH value to 2.5, cool to 2°C, brown crystals are precipitated, and 65% ginkgolic acid is obtained by suction filtration;

[0039] (4) After fully dissolving the brown crystals in step (3) with ethanol at 60°C, filter out the insoluble matter, cool to 13°C, precipitate light brown crystals, and filter to obtain 93% ginkgolic acid;

[0040] (5) Add the light brown crystals of step (4) into water wit...

Embodiment 3

[0042] A kind of industrialized production technology of extracting ginkgolic acid from the outer testa of ginkgo, is characterized in that comprising the following steps:

[0043] (1) Grind the washed ginkgo testa until fine, pass through 80 mesh, add water 10 times the weight, stir and soak for 12 hours;

[0044] (2) Centrifuge the soaked mixed solution to remove slag, pump the filtrate into the concentration pot, fractionate the components at 70°C under a vacuum of 0.09Mpa, and concentrate them;

[0045] (3) Add 30% hydrochloric acid to the concentrated solution to adjust the pH value to 2, cool to -5°C, brown crystals are precipitated, and 70% ginkgolic acid is obtained by suction filtration;

[0046] (4) After fully dissolving the brown crystals in step (3) with ethanol at 70°C, filter out the insoluble matter, cool to -5°C, precipitate light brown crystals, and filter to obtain 95% ginkgolic acid;

[0047](5) Add the light brown crystals in step (4) to 8 times the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com