Heating body of electric heating tap

A technology of electric faucet and heating body, which is applied to valve heating/cooling devices, valve details, engine components, etc. It can solve the problems of burning out the casing, scrapping the machine, uneven heating, etc., and achieves good insulation performance and maintenance. Simple and convenient, improve the effect of heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and drawings of the present invention.

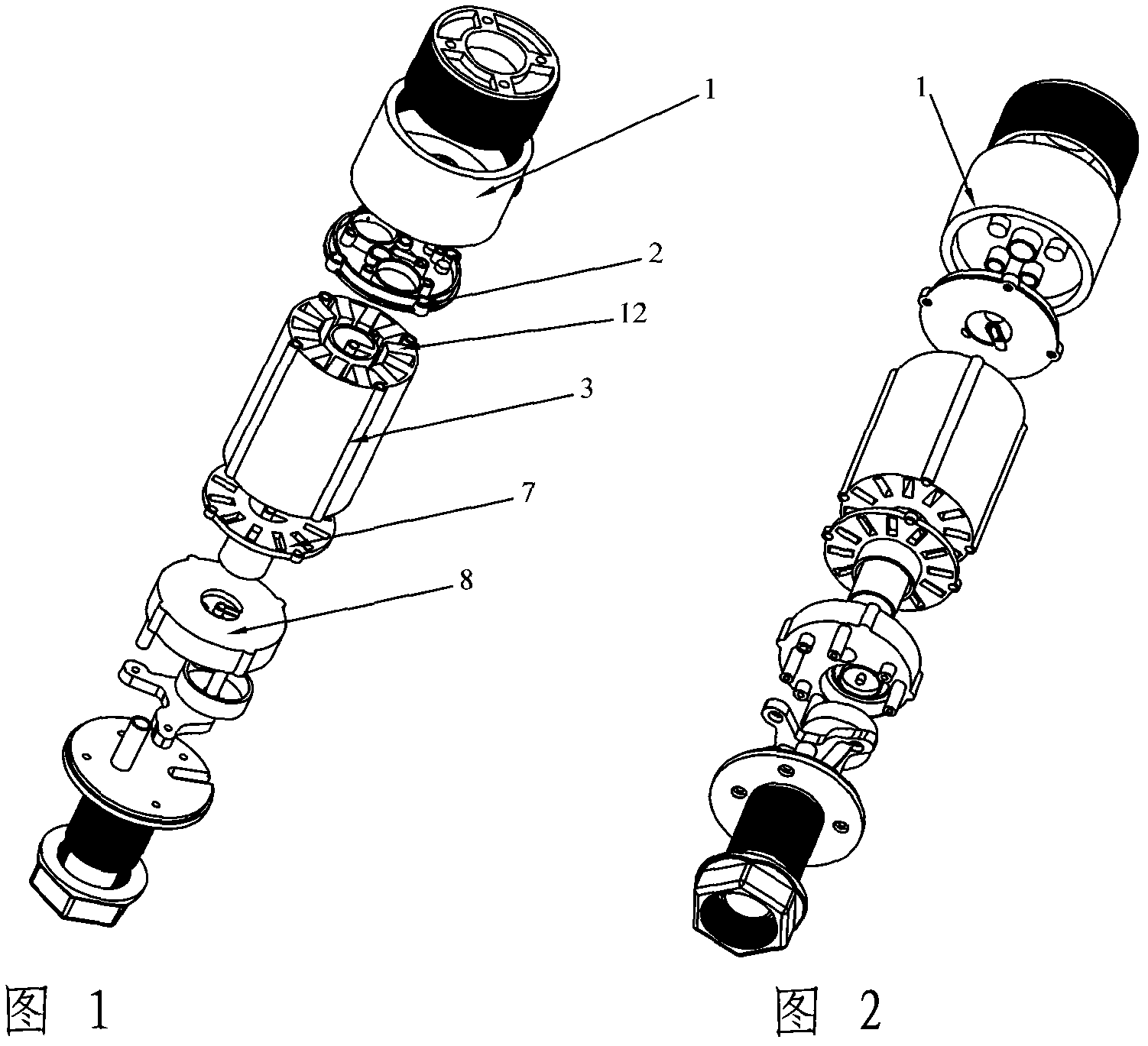

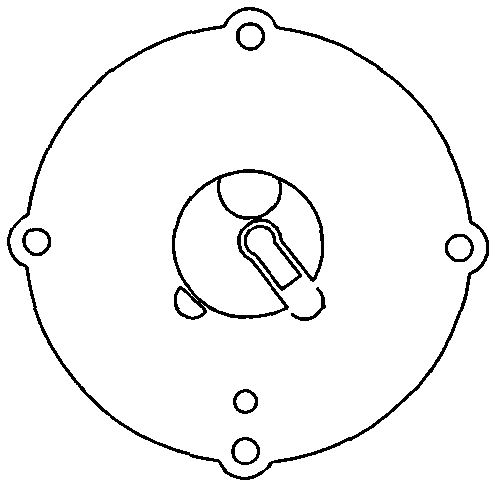

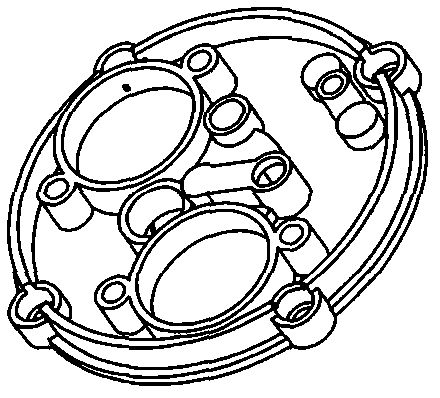

[0043] See Figure 1 to Figure 22 As shown, the present invention provides a heating body of an electric faucet, which includes a water inlet channel 10, a water outlet channel (not shown in the figure), a waterway control system 1, an upper cover 2, a hydroelectric cabin cylinder 3, The lower cover 7, the water pressure switch water flow channel 8, the electricity isolation heat conduction heating sheet 11, the upper cover, the lower cover and the hydroelectric cabin cylinder body cooperate to form a closed heating cabin with hydroelectricity separation; the hydroelectric cabin cylinder body is provided with the water inlet The cold water inlet channel JS of the channel, the water pressure switch water flow channel SY is provided in the hydroelectric cabin c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com