Device and method for real-time testing of volume deformation of cement-based composite materials after hardening

A composite material and volume deformation technology, which is applied in the direction of mechanical solid deformation measurement, etc., to achieve good expansion deformation, wide application range, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Measurement of Volume Deformation of Fly Ash-Slag-Cement Mortar Specimen

[0081] 1) First assemble the test device according to the following steps:

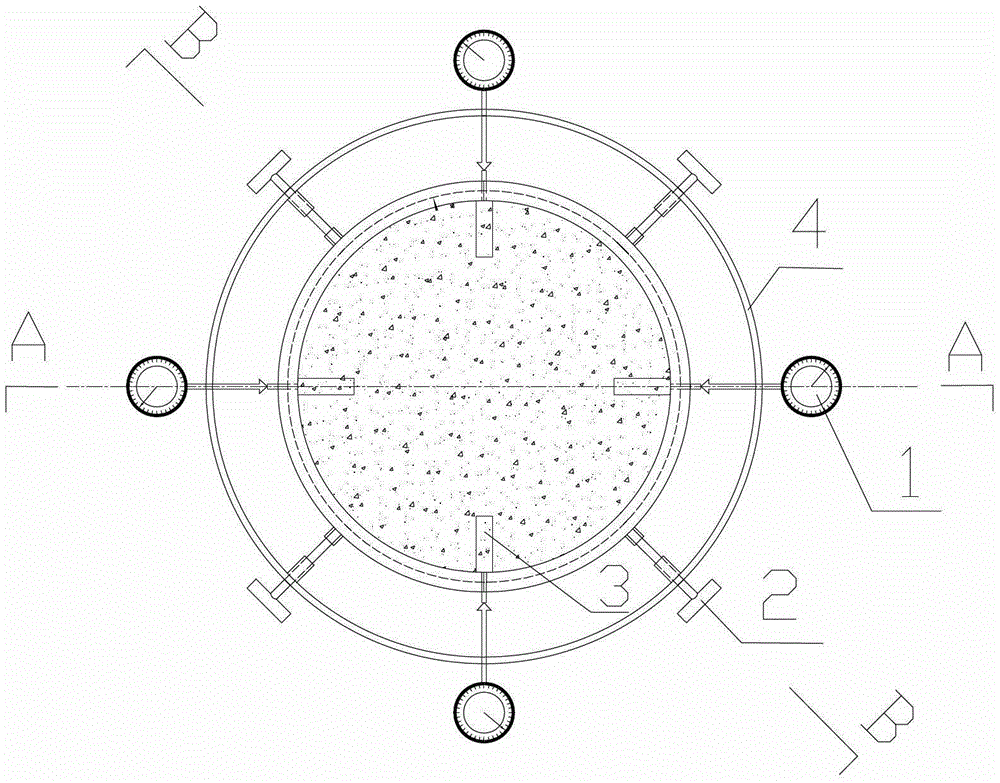

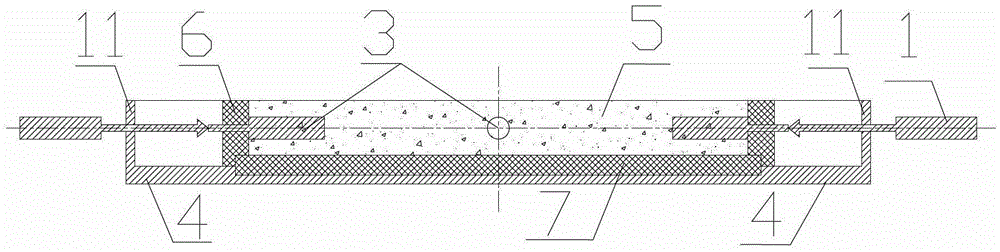

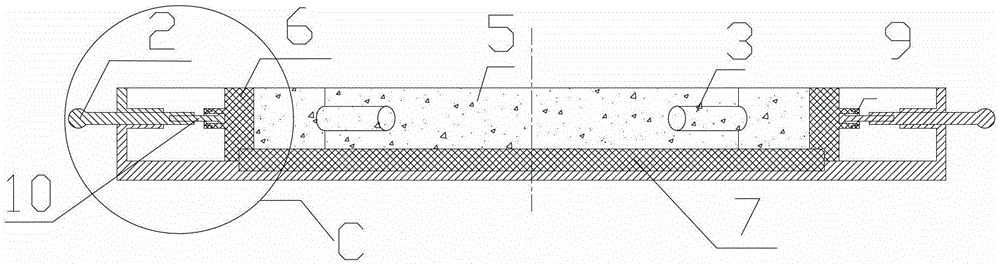

[0082] The circular inner mold 6, the test probe 3, the base backing plate 7, and the contact surfaces of the base and the outer mold 4 formed by splicing four arc-shaped inner molds are evenly brushed with a thin layer of engine oil, and then embedded in the base backing plate 7 , rotate the T-shaped rotary rod 2 and the bolt connecting rod 10 to clamp the circular inner mold 6 on the round edge of the base plate 7, and fit it tightly, and then pass through the reserved hole on the inner mold in a 90° arc Install the position measuring joint 3 at the splicing part of the internal mold, and the test device is assembled. Among them, the height of the inner mold is 30mm, and the inner diameter is 200mm.

[0083] 2) Form the cement-based composite material specimen in the circular inner mold according to the following raw...

Embodiment 2

[0096] Measurement of Volume Deformation of Wet Fly Ash-Desulfurized Gypsum-Cement Mortar Specimens

[0097] 1) First assemble the test device according to the following steps:

[0098] The circular inner mold 6, the test probe 3, the base backing plate 7, and the contact surfaces of the base and the outer mold 4 formed by splicing four arc-shaped inner molds are evenly brushed with a thin layer of engine oil, and then embedded in the base backing plate 7 , rotate the T-shaped rotary rod 2 and the bolt connecting rod 10 to clamp the circular inner mold 6 on the round edge of the base plate 7, and fit it tightly, and then pass through the reserved hole on the inner mold in a 90° arc Install the position measuring joint 3 at the splicing part of the internal mold, and the test device is assembled. Among them, the height of the inner mold is 25mm, and the inner diameter is 250mm.

[0099] 2) Form the cement-based composite material specimen in the circular inner mold according ...

Embodiment 3

[0111] Measurement of volume deformation of mineral powder-desulfurized gypsum-cement mortar specimen

[0112]1) First assemble the test device according to the following steps:

[0113] The circular inner mold 6, the test probe 3, the base backing plate 7, and the contact surfaces of the base and the outer mold 4 formed by splicing four arc-shaped inner molds are evenly brushed with a thin layer of engine oil, and then embedded in the base backing plate 7 , rotate the T-shaped rotary rod 2 and the bolt connecting rod 10 to clamp the circular inner mold 6 on the round edge of the base plate 7, and fit it tightly, and then pass through the reserved hole on the inner mold in a 90° arc Install the position measuring joint 3 at the splicing part of the internal mold, and the test device is assembled. Among them, the height of the inner mold is 20mm, and the inner diameter is 300mm.

[0114] 2) Form the cement-based composite material specimen in the circular inner mold according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com