Polarized light scattering measurement system and method based on magneto-optic modulation

A scattering measurement and magneto-optical modulation technology, applied in the field of measurement, can solve the problem of demanding measurement conditions and achieve the effects of wide applicability, high measurement accuracy, and high signal-to-noise improvement ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

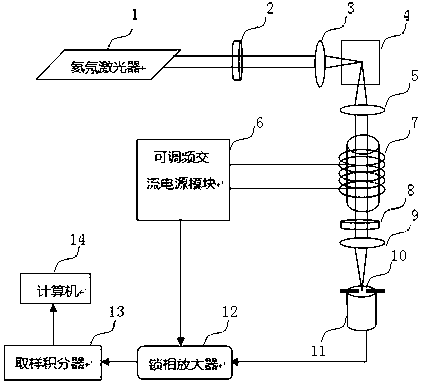

[0021] Such as figure 1 As shown, it includes the incident light path, the output modulation light path and the receiving demodulation part. The incident light path includes a laser 1, a polarizer 2, a focusing lens 3, and a sample matching cell 4 in turn; the output modulation light path includes a beam expander collimator lens in turn. 5. Faraday coil 7, analyzer 8, beam expander lens 9, aperture stop 10; the receiving demodulation part includes photomultiplier tube 11, lock-in amplifier 12, sampling integrator 13 and computer 14 in sequence. The laser 1 provides coherent light; the polarizer 2 converts the incident laser light into linearly polarized light; the focusing lens 3 focuses the polarized light to a point in the solution in the sample matching cell 4, and the beam expander collimating lens 5 reduces the divergence angle of scattered light And expand the diameter of the outgoing light beam; The frequency-adjustable AC power supply module 6 selects a specific freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com