Method using three-dimensional photonic crystals to measure potential of hydrogen (pH)

A photonic crystal, three-dimensional technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of poor stability and low measurement accuracy, and achieve the effect of simple equipment, continuous measurement, and stable measurement value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific implementation mode one: the method for using three-dimensional photonic crystals to measure pH in this implementation mode is implemented according to the following steps:

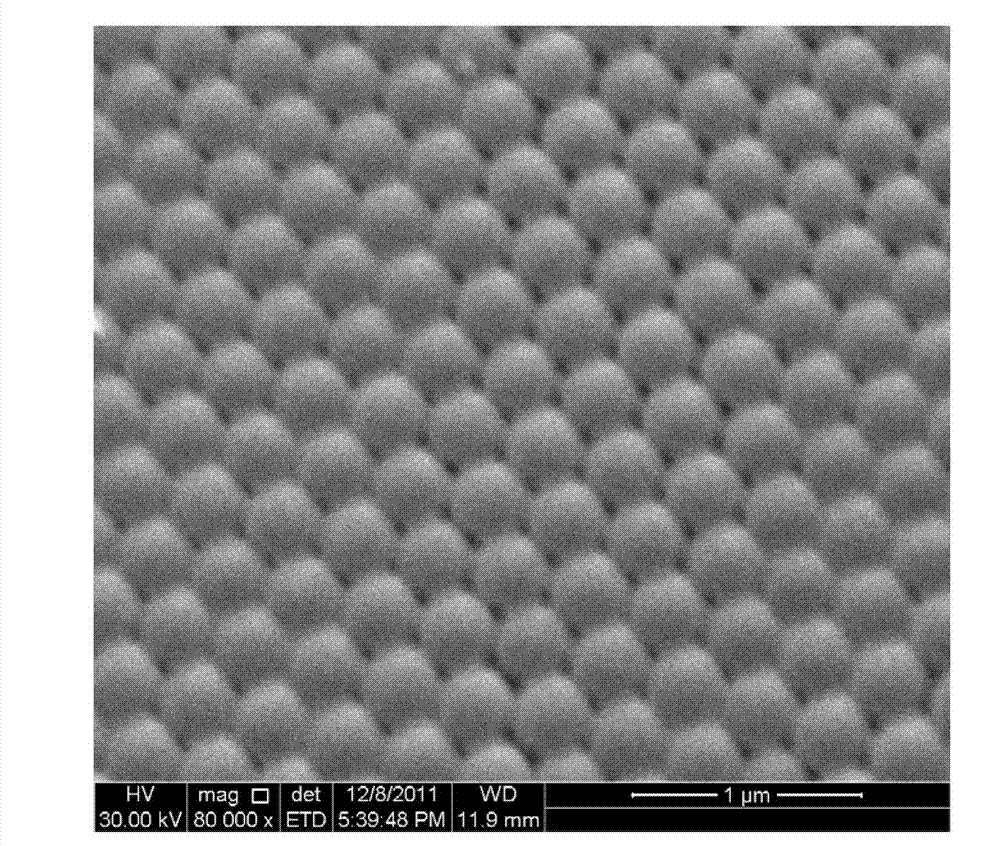

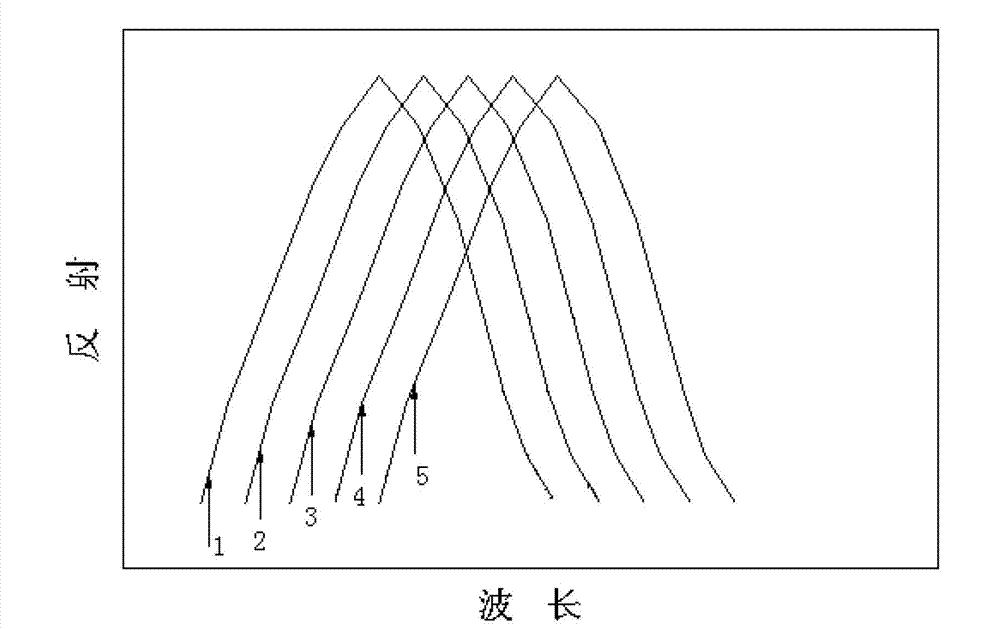

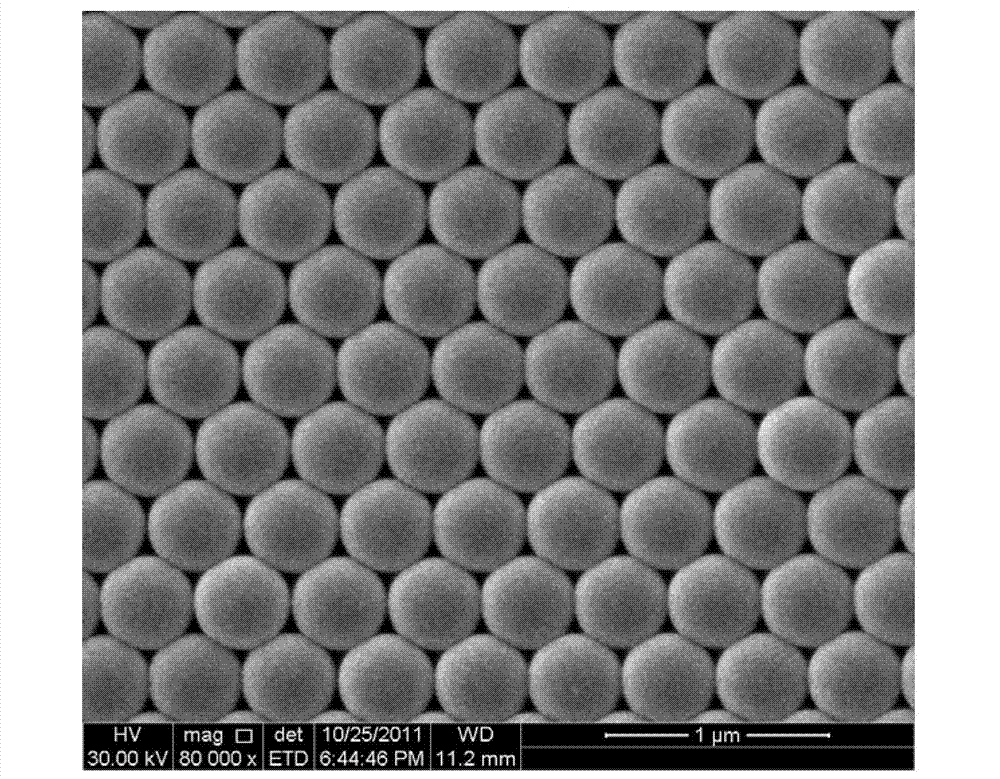

[0015] 1. Pass nitrogen into 90-120mL of ultra-pure water, heat to 65-95°C, keep the temperature for 25-45 minutes, add methacrylic acid and styrene, then adjust the pH of the reaction system to 9-12 with NaOH solution, add 0.184-0.334 g of potassium persulfate, stir evenly, and react at a temperature of 55-75°C for 2-3 hours to obtain a microsphere solution; 2. Add ultrapure water to the microsphere solution to adjust the volume fraction of the microsphere solution to 0.1%-0.3 %, put it in a constant temperature box, and deposit a photonic crystal film at a temperature of 50-70°C for 4-6 days to obtain a photonic crystal film; 3. Put the photonic crystal film obtained in step 2 into solutions with different pH values, and use a spectrometer to sequentially measure the photonic crystal film...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that the stirring speed in Step 1 is 150 r / min. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that step 1 is reacted at a temperature of 60-70°C for 2-3 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com