Miniature microwave plasma electrodeless metal halide lamp

A microwave plasma and electrodeless technology, which is applied to discharge lamps, circuits, electrical components, etc., can solve the problems of increased operating frequency, increased manufacturing cost, and increased microwave loss in resonant cavities, achieving reduced space, reduced processing costs, and reduced The effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

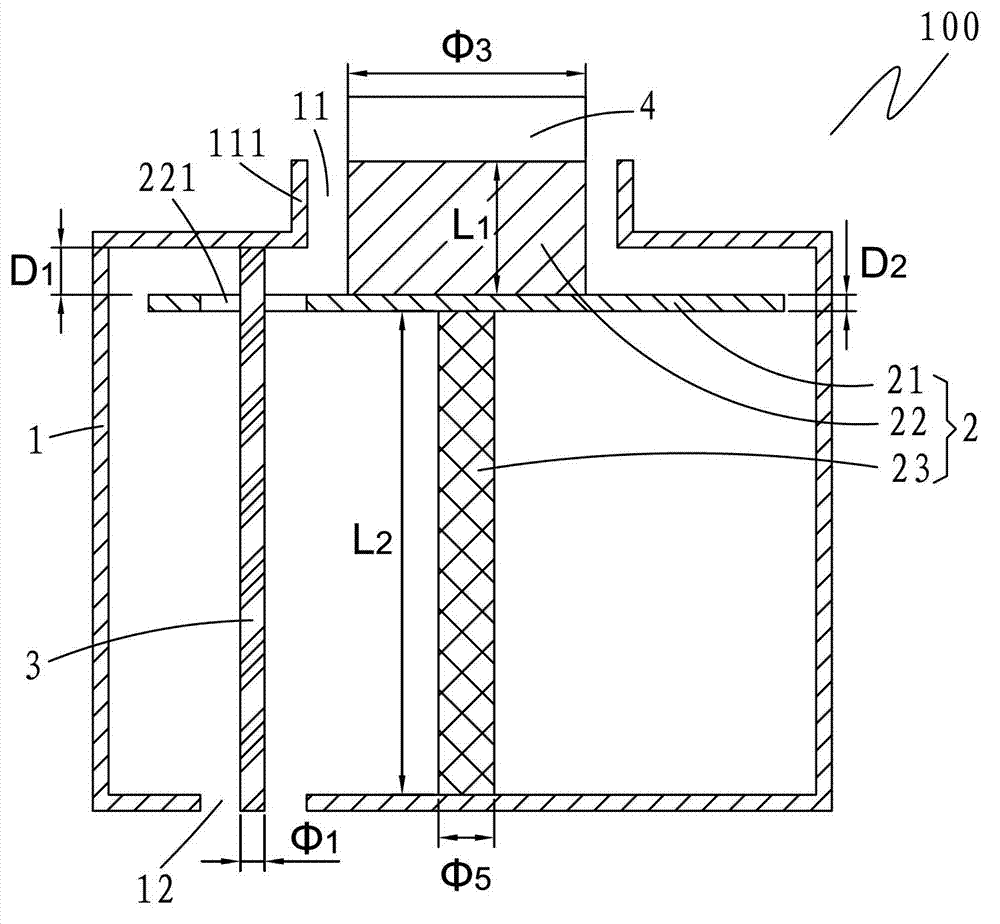

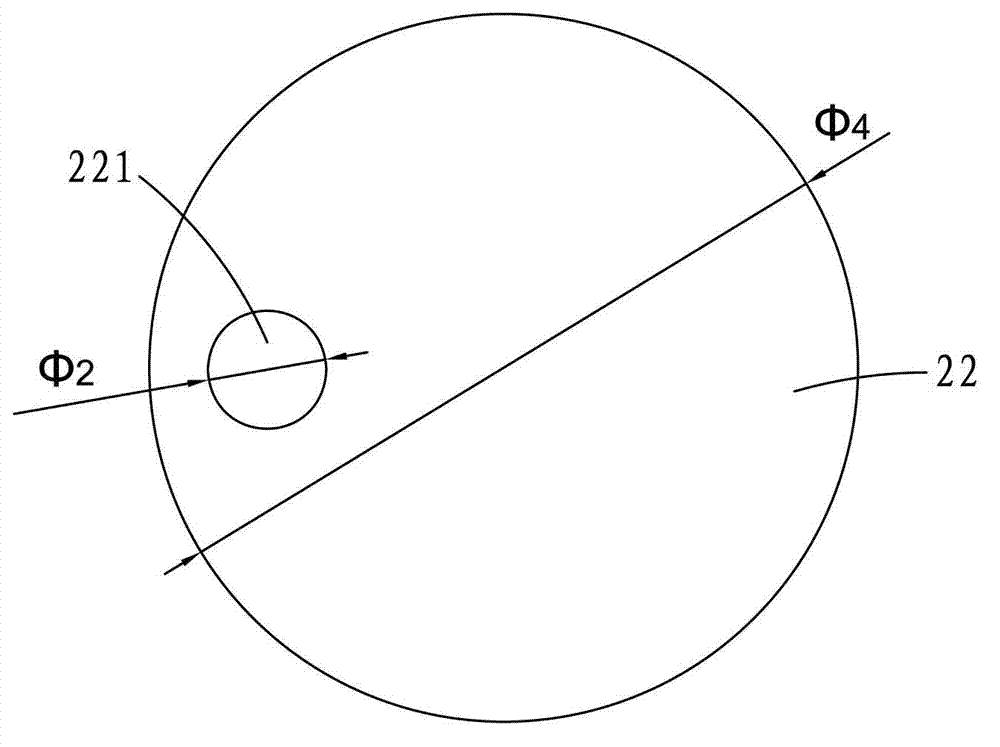

[0018] see figure 1 and figure 2 As shown, a miniaturized microwave plasma electrodeless metal halide lamp 100 includes a hollow resonant cavity 1, a coupling unit 2, and a feed probe for connecting a coaxial line (not shown) of a solid-state microwave source. needle 3 and a light bulb 4; the coupling unit 2 is fastened and inserted in the resonant cavity 1 from top to bottom through a first opening 11; the light bulb 4 is arranged on the upper end of the coupling unit 2; The feeding probe 3 is fastened and inserted in the resonant cavity 1 from bottom to top through a second opening 12; the coupling unit 2 includes a first coupling part 21, a second The coupling part 22 and the third coupling part 23; the first coupling part 21 and the third coupling part 23 are cylinders; the second coupling part 22 is a disc; the diameter of the first coupling part 21 is Φ 3 , the diameter Φ of the third coupling part 23 5 are smaller than the diameter Φ of the second coupling part 22 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com