Raw materials for cigarettes, production method and equipment thereof

A production method and technology of raw materials, applied in the field of tobacco, can solve the problems that do not conform to the basic principle of microwave expansion, the internal structure of tobacco stems is easily damaged, and the shredded tobacco stems are easy to be broken, so as to achieve significant effects of tar reduction and harm reduction, and ease Tobacco leaf raw material pressure, the effect of reducing the release of tar and harmful components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

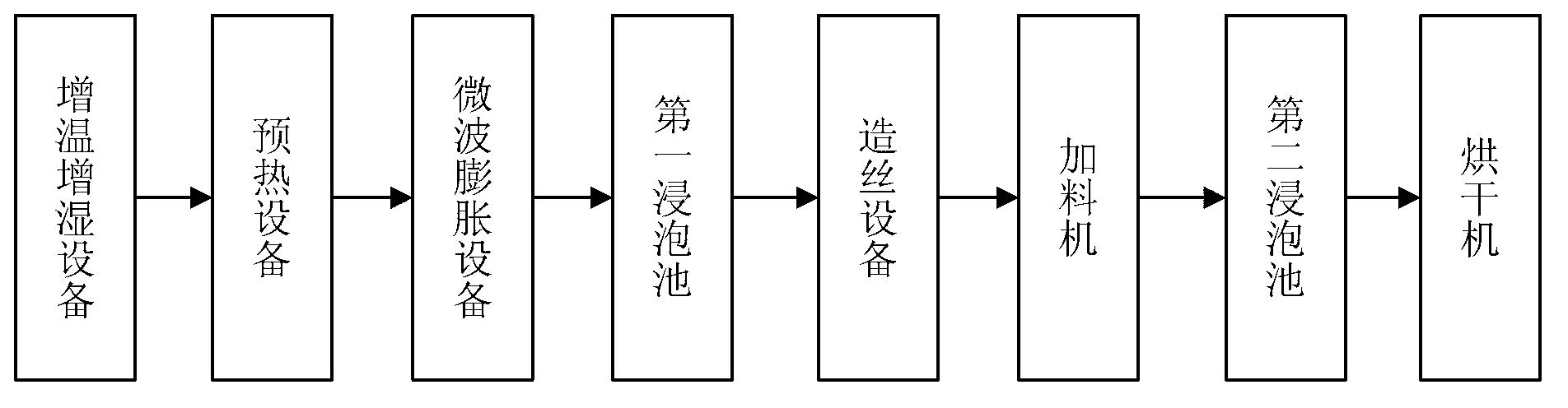

[0071] figure 1 It is a schematic diagram of the connection of the tobacco raw material production equipment in Example 1 of the present invention.

[0072] This embodiment discloses a method for producing raw materials for tobacco. The method uses tobacco stems as raw materials and adopts figure 1 The tobacco raw material production equipment shown specifically includes the following steps:

[0073] (1) Warming and humidifying the tobacco stems in a drum humidifier until the water content is 38wt%;

[0074] (2) Preheat the heated and humidified tobacco stems to 90°C in the steam heating equipment;

[0075] (3) Place the preheated tobacco stems in the microwave expansion equipment to make them microwave expanded until the water content in the tobacco stems drops to 15wt%; the microwave expansion makes the moisture in the tobacco stems evaporate rapidly, thereby completing the synchronization of the cells in the tobacco stems Uniform puffing;

[0076] (4) soaking the tobacc...

Embodiment 2

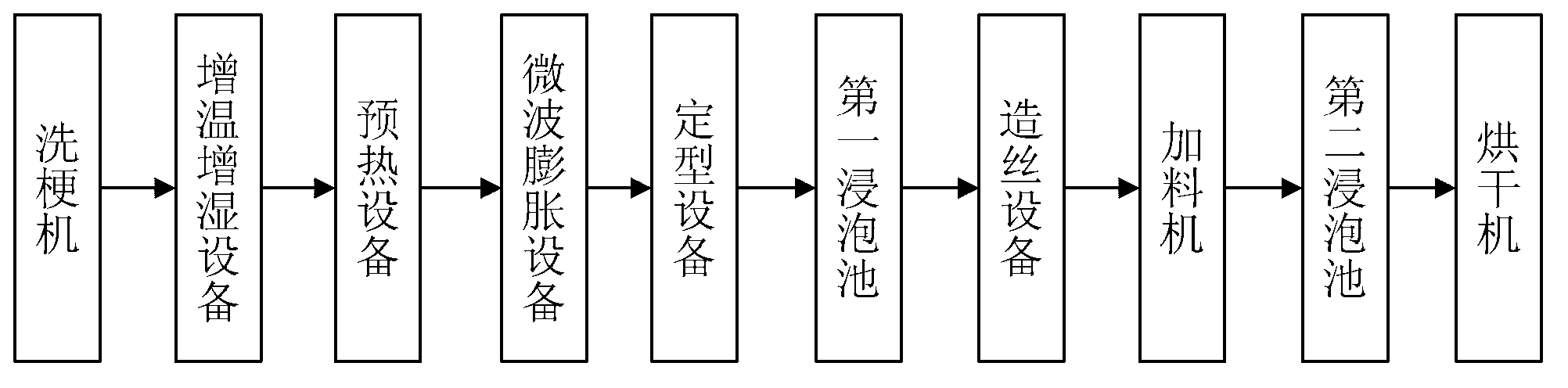

[0084] figure 2 It is a schematic diagram of the connection of the tobacco raw material production equipment in Example 2 of the present invention.

[0085] This embodiment discloses a method for producing raw materials for tobacco, using tobacco stems as raw materials, using figure 2 The tobacco raw material production equipment shown, the production of the tobacco raw material includes the following steps:

[0086] (1) washing the tobacco stems with water to remove dust, and the water content of the tobacco stems after washing reaches 25wt%;

[0087] (2) Warming and humidifying the tobacco stems in a tunnel vibrating tank humidifier until the water content is 35wt%;

[0088] (3) Preheat the heated and humidified tobacco stems to 85°C in microwave heating equipment, so that the temperature of the moisture in the tobacco stems is close to the boiling point;

[0089] (4) Place the preheated tobacco stems in the microwave expansion equipment, and microwave the expansion unt...

Embodiment 3

[0100] This embodiment is basically the same as Embodiment 2, except that this embodiment uses cumin stems as raw materials. The prepared raw material for tobacco needs to be flavored, that is, the step (9) is: after drying, the raw material for tobacco needs to be added, dried and flavored.

[0101] The tobacco raw materials produced in this example are processed into cigarettes, which also have the advantages of high filling value, light woody gas, comfortable taste, soft smoke and reduced tar in cigarettes, and can also be added to high-grade cigarettes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com