Paclitaxel polymer nanoparticle and preparation method

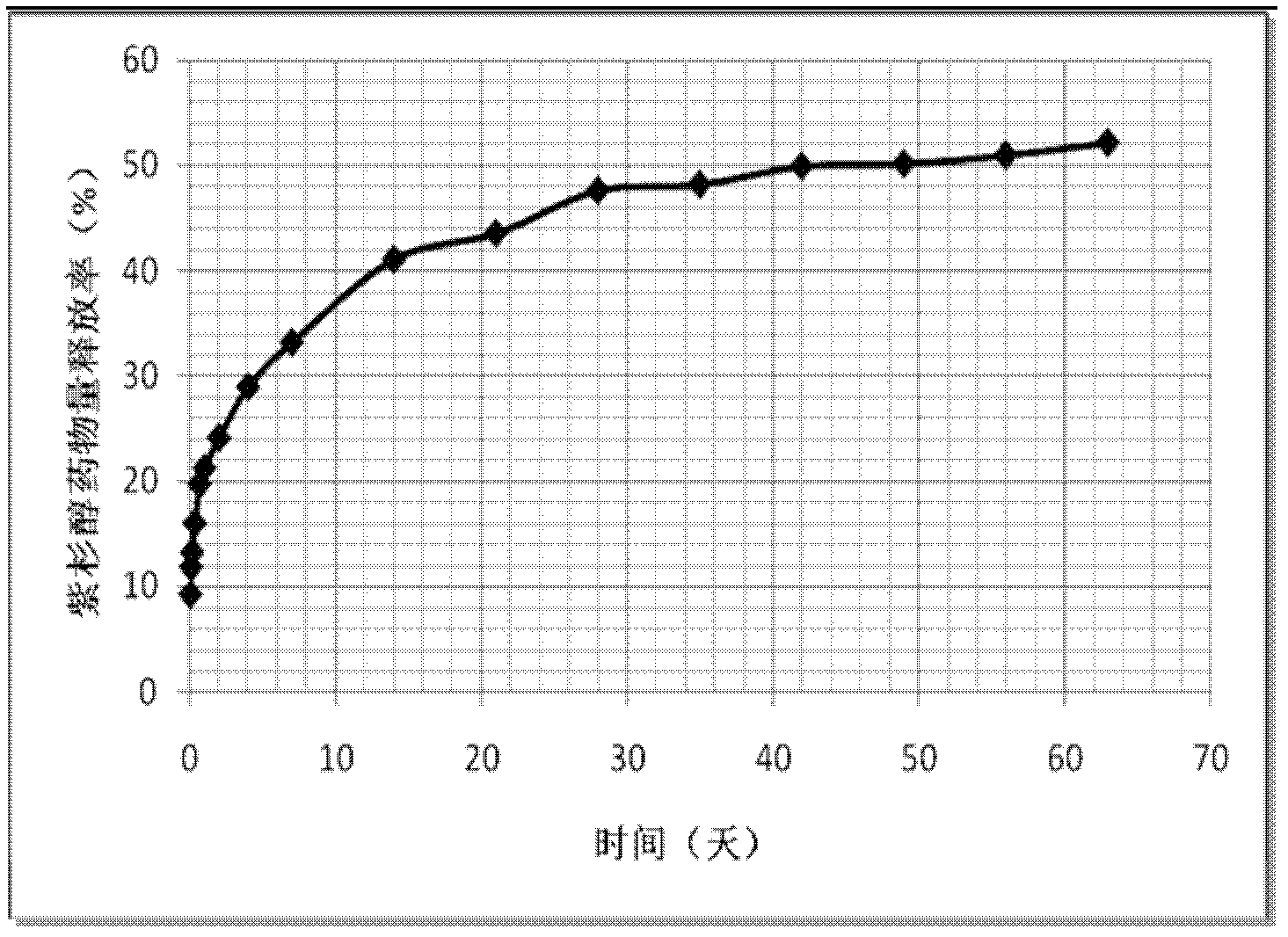

A nanoparticle and paclitaxel technology, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problem that the release speed of polylactic acid cannot be adjusted, by-products and raw material residues, preparation The problem of complex process, etc., to avoid the residue of by-products and catalysts, low cost, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

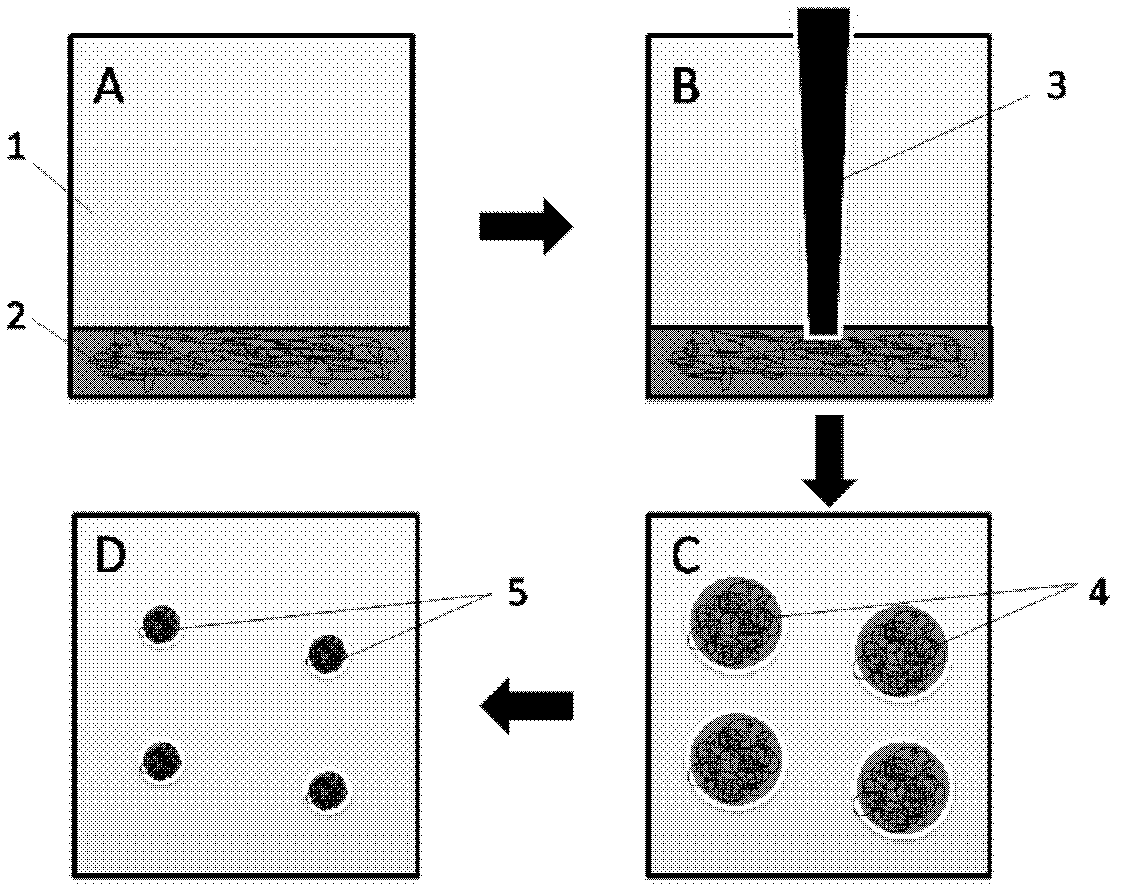

Method used

Image

Examples

Embodiment 1

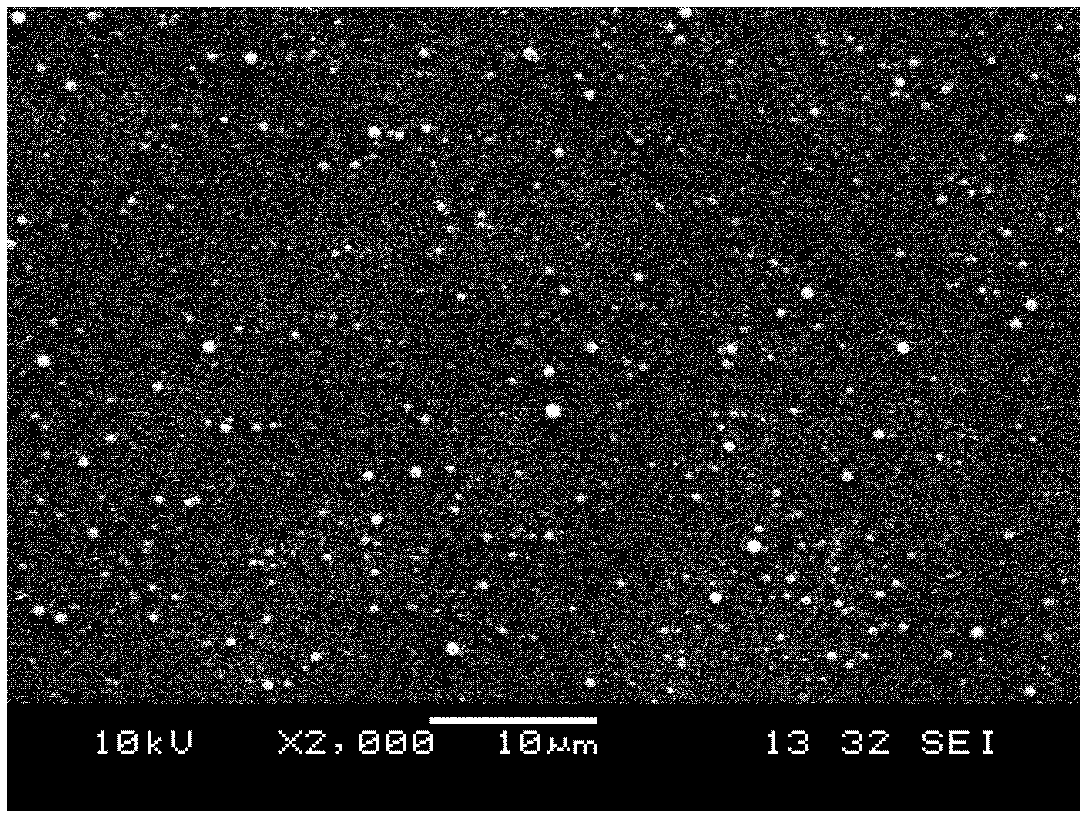

[0037] Investigate the effect of polymer material type on paclitaxel / polylactic acid nanoparticles. Weigh 3 g of polylactic acid, poly(lactic acid-glycolic acid) (lactic acid: glycolic acid = 50: 50), polyhydroxybutyric acid, polyhydroxybutyric acid / polylactic acid (polyhydroxybutyric acid: polylactic acid = 50: 50 ) mixtures were respectively dissolved in 100ml of dichloromethane, magnetically stirred at room temperature to dissolve until completely dissolved, 0.3g of paclitaxel was added, and magnetically stirred for 10 minutes until uniformly dissolved to form an organic phase. Weigh 30g of polyvinyl alcohol and dissolve it in 1000ml of water, dissolve at high temperature for 1 hour until completely dissolved and cool to room temperature to form a water phase. Take out 2ml of the above-mentioned organic phase and 200ml of the aqueous phase and place them in a dry beaker, and perform ultrasonic treatment at 100W for 10 minutes (work for 3 seconds, rest for 3 seconds) to form...

Embodiment 2

[0043]Investigate the effect of organic solvent types on paclitaxel / polylactic acid nanoparticles. Weigh 1g of polyhydroxybutyric acid / polylactic acid (polyhydroxybutyric acid:polylactic acid=50:50) mixture and dissolve in 100ml of dichloromethane, chloroform, dichloromethane / chloroform 1:1 mixture , magnetic stirring at room temperature until completely dissolved, adding 0.3 g of paclitaxel, and continuing magnetic stirring for 10 minutes until uniformly dissolved, forming an organic phase. Weigh 30g of polyvinyl alcohol and dissolve it in 1000ml of water, dissolve at high temperature for 1 hour until completely dissolved and cool to room temperature to form a water phase. Take out 40ml of the above-mentioned organic phase and 200ml of the aqueous phase and place them in a dry beaker, and perform ultrasonic treatment at 100W for 10 minutes (work for 3 seconds, rest for 3 seconds) to form an emulsion. Immediately pour the emulsion into a rotary evaporator to remove the organi...

Embodiment 3

[0049] The effect of the concentration of polymer materials in the organic phase on paclitaxel / polylactic acid nanoparticles was investigated. Weigh 0.5g, 1g, 2g, 3g of polyhydroxybutyric acid\polylactic acid (polyhydroxybutyric acid:polylactic acid=50:50) mixture and dissolve in 100ml dichloromethane / chloroform 1:1 mixture , magnetically stirred at room temperature until completely dissolved, then added 0.3 g of paclitaxel, and continued to magnetically stir for 10 minutes until uniformly dissolved and an organic phase was formed. Weigh 30g of polyvinyl alcohol and dissolve it in 1000ml of water, dissolve at high temperature for 1 hour until completely dissolved and cool to room temperature to form a water phase. Take out 10ml of the above-mentioned organic phase and 200ml of the aqueous phase and place them in a dry beaker, and perform ultrasonic treatment at 100W for 10 minutes (work for 3 seconds, rest for 3 seconds) to form an emulsion. Immediately pour the emulsion into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com