Melting method of bonded iron on hot-metal ladle

A molten iron tank and iron sticking technology, applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of high labor intensity, long processing time, environmental pollution, etc., to save processing costs and achieve a high degree of automation. , the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

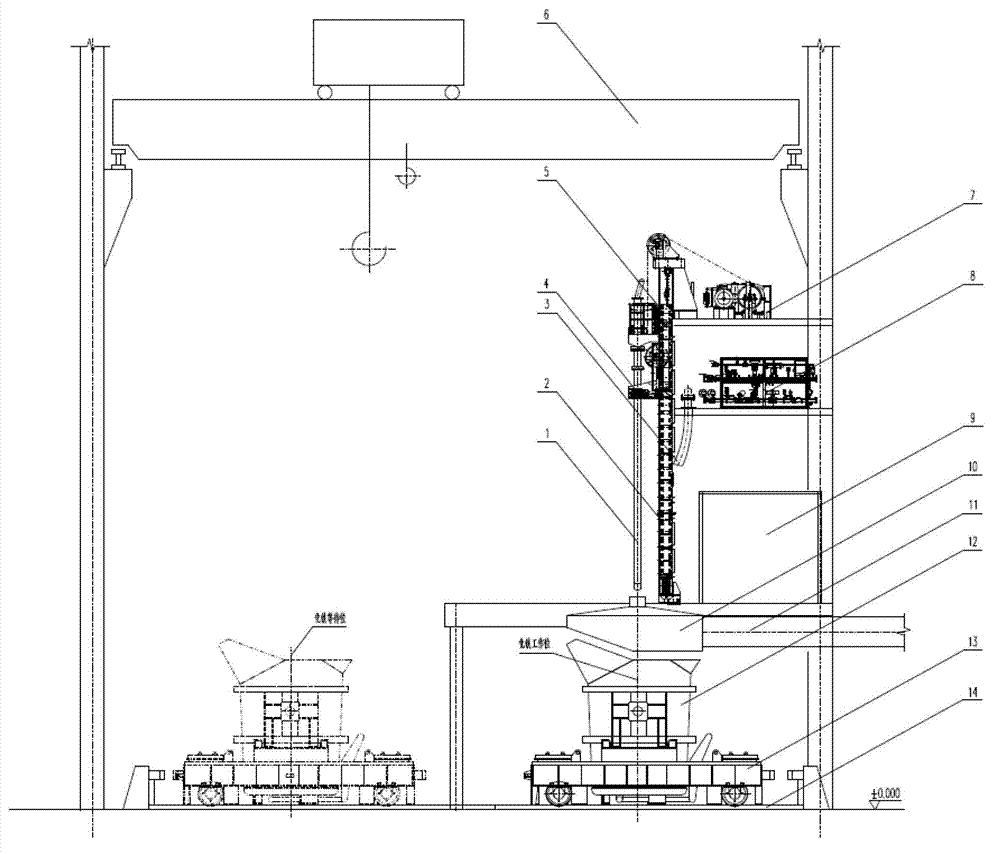

[0022] figure 1 It is a specific embodiment of the present invention. Below in conjunction with accompanying drawing to further explanation:

[0023] The facility of the present invention includes a chemical iron gun mechanism 5, gun body cooling water and gas and oxygen metal hose 3, gun body cooling water and gas and oxygen valve station 8, smoke and dust collection cover 10, dust removal pipeline 11, molten iron tank 12, molten iron The tank transport vehicle 13, the described iron gun mechanism 5 includes an oxygen combustion gun 1, a lifting slideway 2, a lifting trolley 4, and a lifting winch mechanism 7. The process steps are as follows:

[0024] First, use the crane 6 in the workshop to hoist the molten iron tank 12 of sticking iron to the molten iron tank transport vehicle 13 parked on the waiting position for melting iron; then drive the molten iron tank transport vehicle 13 to the melting iron working position. Then, the iron gun 1 is lowered, and the lifting tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com