A New Tube Sheet Welding Method

A technology of tube-sheet welding and welding tools, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of insufficient welding strength and unweldable materials, and achieve high welding strength, small residual stress and deformation, and smooth welding The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

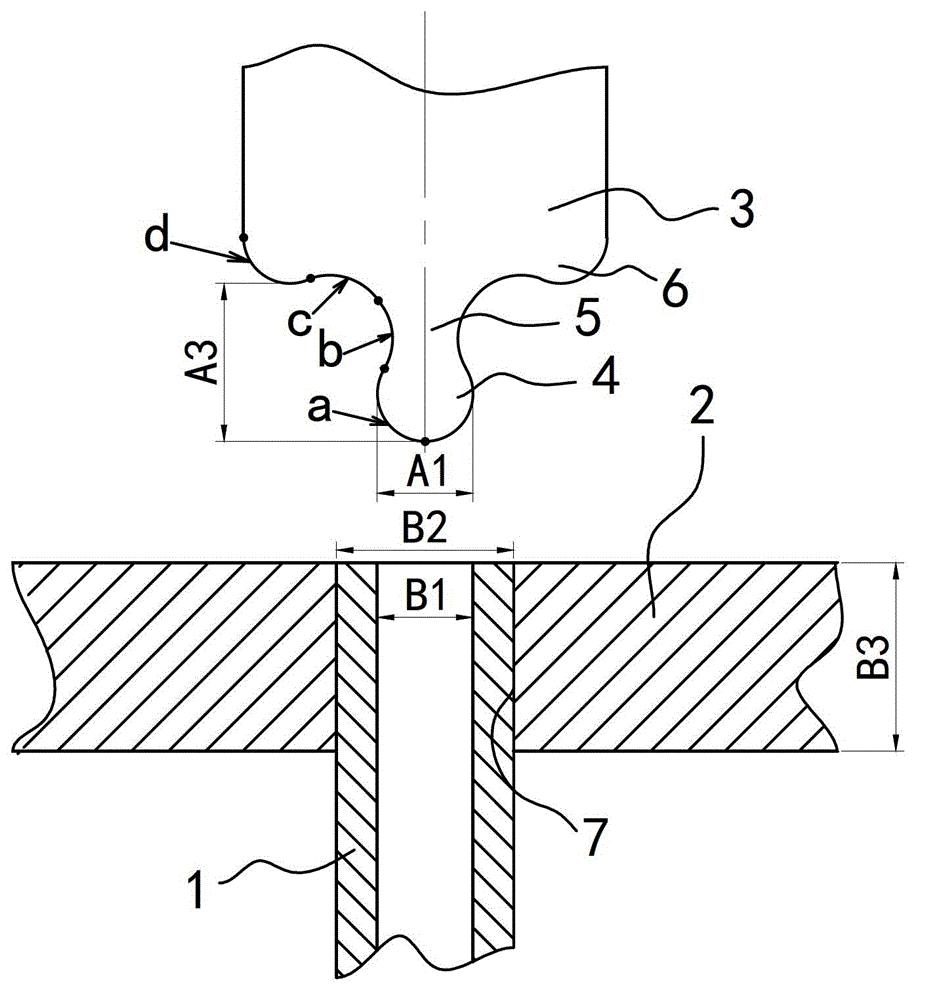

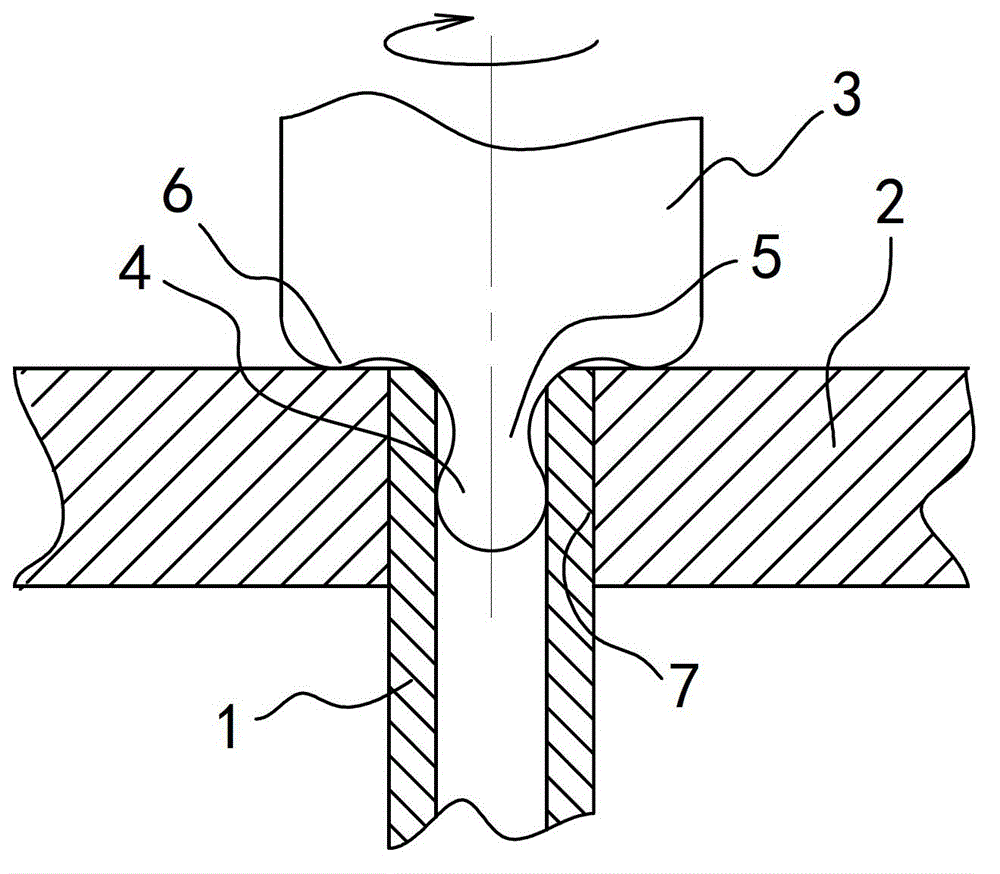

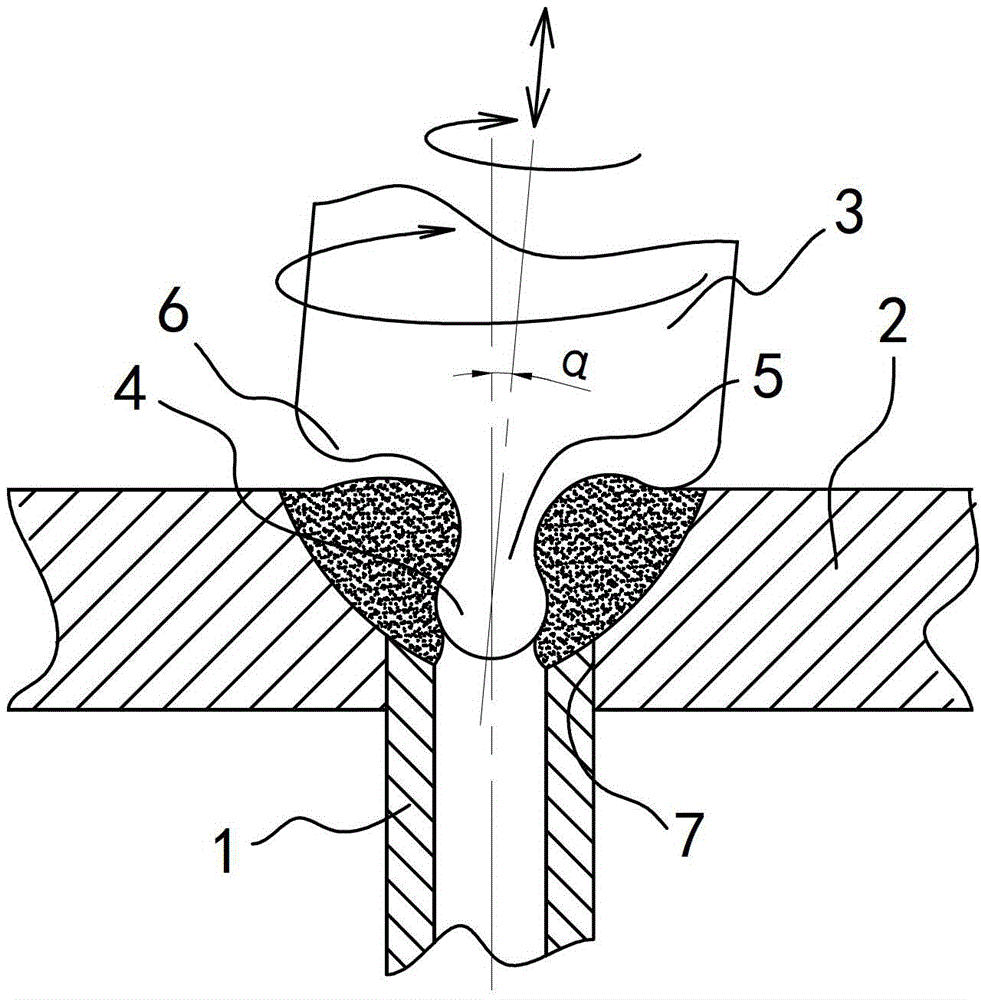

[0030] Embodiment one: see attached figure 1 - attached Figure 5 Shown:

[0031] A new tube-sheet welding method, aiming at the connection objects of the tube 1 and the plate 2, adopts the rotating welding tool 3 to realize the welding of the tube 1 and the plate 2 through friction, stirring and upsetting.

[0032] (1) Welding tools

[0033] as attached figure 1 As shown, the welding tool 3 has a cylinder, one end of the cylinder is the working end for welding, and the working end is a rotating body structure formed by rotating the generatrices of each section around the axis of the cylinder. The cylinder is composed of ball head 4, neck 5 and shoulder 6 connected in sequence in the axial direction. The ball head 4 is located at the center of the front end of the working end, the shoulder 6 is located at the peripheral position of the rear end of the working end, and the neck 5 is located at the center of the ball head. 4 and the position between the shoulder 6. The gene...

Embodiment 2

[0047] Embodiment two: see attached figure 1 - attached Figure 5 Shown:

[0048] A new tube-sheet welding method, aiming at the connection objects of the tube 1 and the plate 2, adopts the rotating welding tool 3 to realize the welding of the tube 1 and the plate 2 through friction, stirring and upsetting. The structure of the welding tool 3 and the welding steps are generally the same as the first embodiment, the difference is: the specific parameters of the tube 1 and the plate 2: the material of the tube 1 is aluminum alloy of 6063 grade, the outer diameter B2 of the tube 1 is 8mm, and the tube 1 The wall thickness is 1 mm, the material of the plate 2 is steel, the thickness B3 of the plate 2 is 5 mm, and the depth of the weld 8 required for welding is 3 mm. For this pipe 1 and plate 2, the apex diameter A2 of the fourth arc segment d on the shoulder 6 of the welding tool 3 can be set to about 12 mm, and the diameter A2 of the vertex of the ball head 4 of the welding too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com