Preparation method of high monofilament cohesive force polyurethane elastic fiber

A technology of polyurethane elasticity and cohesion, which is applied in the field of improving the cohesion between polyurethane elastic fiber monofilaments and multi-fila coarse denier yarns, and can solve problems such as unclearness, poor cohesion, and splitting, and achieve simple process principles and improved Effect of unwinding and cohesion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

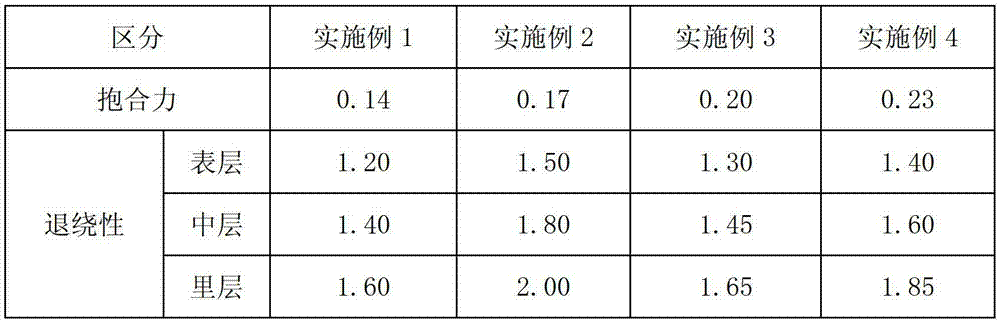

Embodiment 1

[0015] Solvent is not included in the polyurethane stock solution, the mass percentage range of magnesium stearate is 0.1%; 0.1-0.5%. In the spinning and oiling process, the content of magnesium stearate in the silicone oil is 0.5%, and the oiling rate is 4.0%. The other processes are conventional dry spinning processes to produce 30D polyurethane elastic fibers.

Embodiment 2

[0017] Solvent is not included in the polyurethane stock solution, the mass percentage range of magnesium stearate is 0.1%; 0.1-0.5%. In the spinning and oiling process, the content of magnesium stearate in the silicone oil is 1.0%, and the oiling rate is 3.0%. The other processes are conventional dry spinning processes to produce 30D polyurethane elastic fibers.

Embodiment 3

[0019] Solvent is not included in the polyurethane stock solution, the mass percentage range of magnesium stearate is 0.05%, the mass percentage range of antioxidant is 0.1-1.5%, the mass percentage range of dyeing agent is 0.1-0.5%, and the mass percentage range of anti-yellowing agent 0.1-0.5%. In the spinning and oiling process, the content of magnesium stearate in the silicone oil is 1.0%, and the oiling rate is 5.0%. The other processes are conventional dry spinning processes to produce 30D polyurethane elastic fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com