Integrated driller monitoring system

A monitoring system and drilling rig technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of difficult management, complicated wiring, low integration, etc., and achieve the effect of saving hardware costs, saving space, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

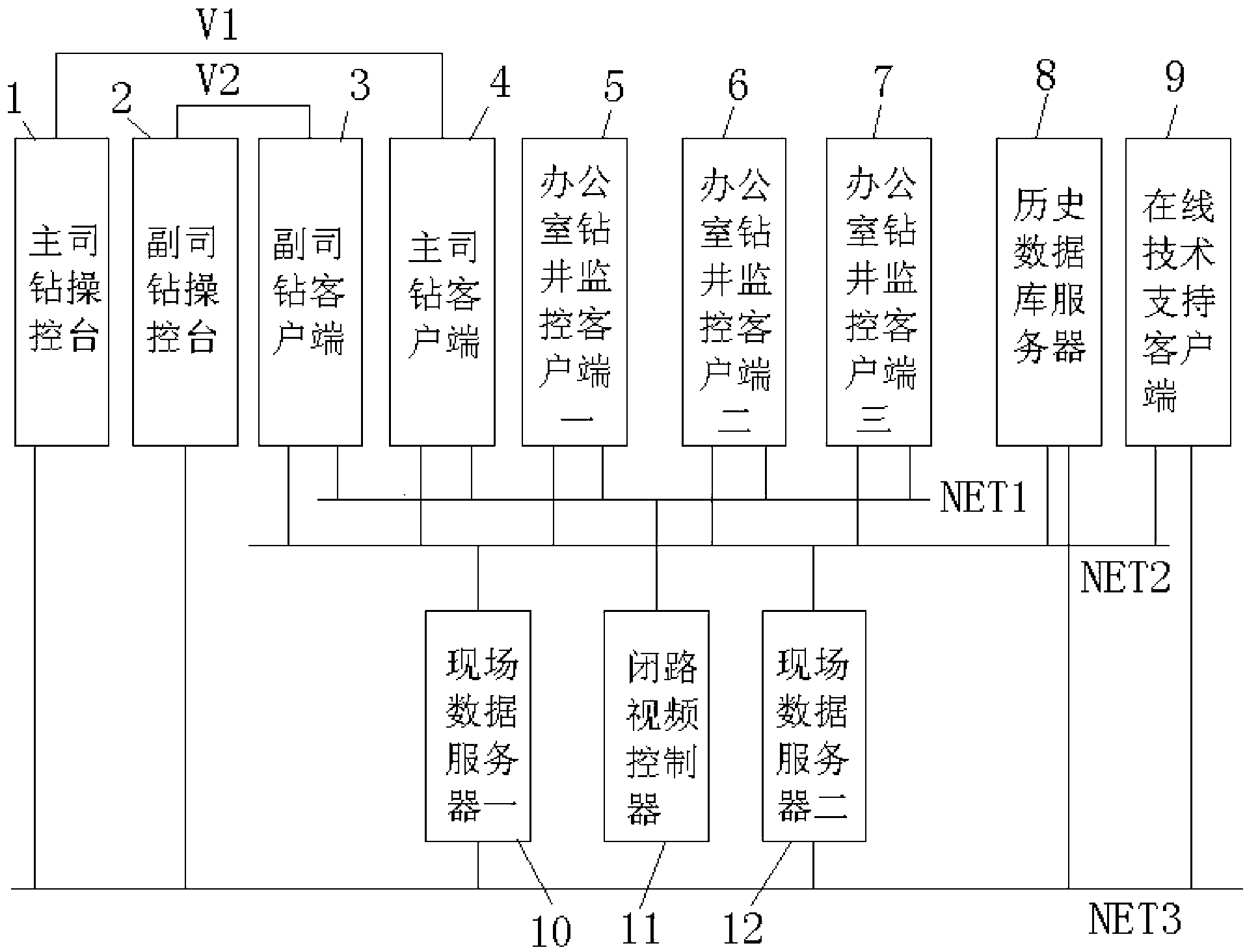

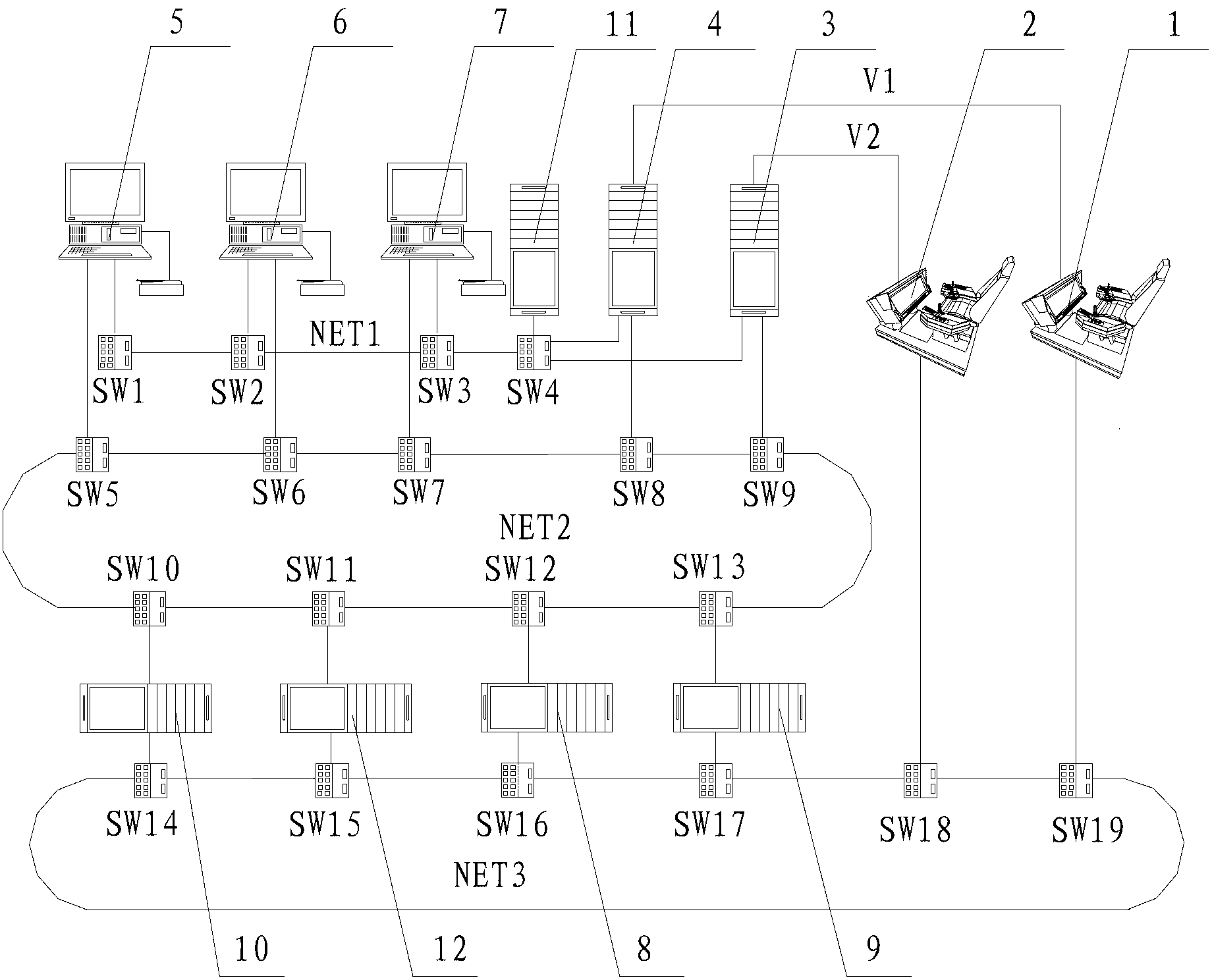

[0017] refer to figure 1 , the structure of the drilling rig integrated monitoring system of the present invention is that it includes the master driller's console 1, the assistant driller's console 2, the assistant driller's client 3, the master driller's client 4, and multiple office drilling monitoring clients ( figure 1 The embodiment only shows drilling monitoring client one 5, drilling monitoring client two 6, drilling monitoring client three 7), historical database server 8, online technical support client 9, closed-circuit video controller 11, two field data Servers (on-site data server one 10 and on-site data server two 12 ), industrial closed-circuit television monitoring video network NET1, upper layer data monitoring communication network NET2, and on-site data communication network NET3. Among them, the historical database server 8, the online technical support client 9 and two field data servers are simultaneously connected to the upper layer data monitoring comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com