Magnetizing power source for magnetic defect detector

A technology of magnetic particle inspection and power supply, applied in the field of power supply, can solve the problems of short use time, short battery life, potential safety hazards, etc., and achieve the effect of stable operation and increased battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

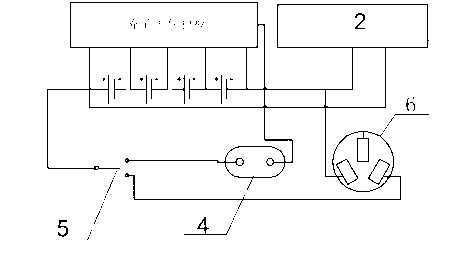

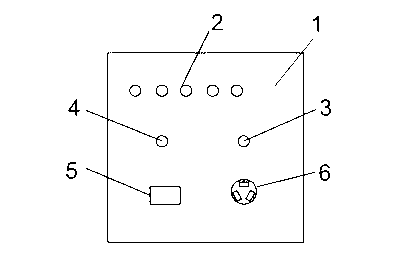

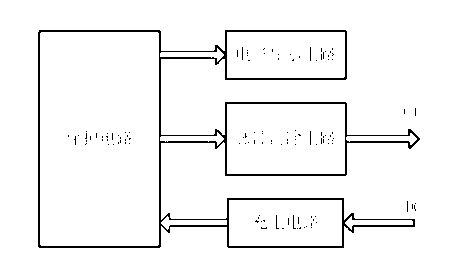

[0026]The magnetizing power supply for the magnetic particle flaw detector is characterized in that it includes the overall chassis 1 and the power supply inside the box, a charging circuit, a protection circuit, a power display circuit, a pulse elimination circuit and a charging circuit, and the overall chassis 1 is provided with a power indicator board 2 , fuse socket 3, charging socket 4, power switch 5 and output socket 6, the protection circuit is connected to the pulse elimination circuit, the protection circuit is connected to the power display circuit, and the protection circuit is connected to the pulse elimination circuit;

[0027] The charging circuit is controlled by the control chip IC4 as the central control element. The 15 pins of the circuit IC4 and the internal connection circuits of the 2 and 3 pins supply power for the power part and the analog part of the IC2 circuit respectively. , the other end of the capacitor is connected to the charging input positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com