Regeneration method of deactivated titanium-silicon molecular sieve catalyst

A titanium-silicon molecular sieve and catalyst technology, which is applied in the field of regeneration of deactivated titanium-silicon molecular sieve catalysts, can solve the problems of cumbersome and complicated operation process, high material consumption and energy consumption, environmental protection and economical restrictions, etc., and achieves cost reduction and three waste emissions. , the effect of relative crystallinity recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

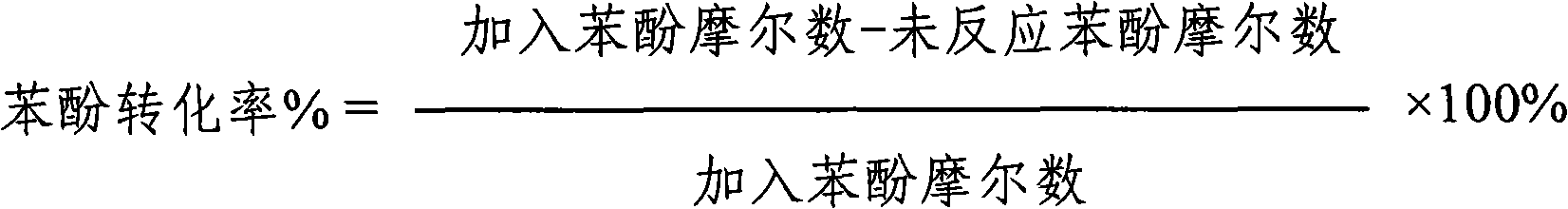

[0034] This example illustrates the process of regenerating the titanium-silicon molecular sieve catalyst deactivated in the hydroxylation reaction of phenol by the method of the present invention.

[0035] Take 10 g of the above-mentioned inactivated molecular sieve SH-1 and mix it with 6.5 g of filtered waste liquid (from Comparative Example 1, the same below). The mixture was charged into a 50 mL polytetrafluoroethylene liner and placed in a 100 mL polytetrafluoroethylene liner, and then reacted at 180° C. for 12 h in a sealed autoclave. The obtained molecular sieve was dried at 150° C. for 120 minutes, and then calcined at 650° C. for 4 hours to obtain regenerated TS-1 molecular sieve A.

Embodiment 2

[0037] This example illustrates the regeneration process of the deactivated titanium-silicon molecular sieve catalyst in the ammoximation reaction of cyclohexanone using the method of the present invention.

[0038] Take 12g of SH-2 obtained by regenerating and deactivating TS-1 molecular sieve, and mix it with 4.5g of filtered waste liquid. The mixture was filled into 50mL polytetrafluoroethylene liner and placed on the support of 100mL polytetrafluoroethylene liner, while 5mL of water was added under it, and then reacted at 145°C for 54h in a sealed autoclave. The obtained molecular sieve was dried at 100° C. for 270 minutes, and then calcined at 570° C. for 8 hours to obtain regenerated TS-1 molecular sieve B.

Embodiment 3

[0040] This example illustrates the regeneration process of the deactivated titanium-silicon molecular sieve calcined catalyst by the method of the present invention in the phenol hydroxylation reaction.

[0041] Take 12 g of BS-1 obtained by roasting and regenerating inactivated TS-1 molecular sieve, and mix it with 1.5 g of filtered waste liquid. Put the mixture into 50mL polytetrafluoroethylene liner and place it on the support of 100mL polytetrafluoroethylene liner, add water 5mL under it at the same time, and then react in a sealed autoclave at 150°C for 24h. The obtained molecular sieve was dried at 160° C. for 120 minutes, and then calcined at 700° C. for 2 hours to obtain the regenerated TS-1 molecular sieve C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com