Regeneration method of coal liquefied oil hydrogenation deactivated catalyst

A technology for deactivating catalysts and coal liquefied oil, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of large loss of catalyst activity, reduction of catalyst cost, deterioration of catalyst properties, etc. Achieve the effect of high equipment and operating costs, reducing costs, and reducing production and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

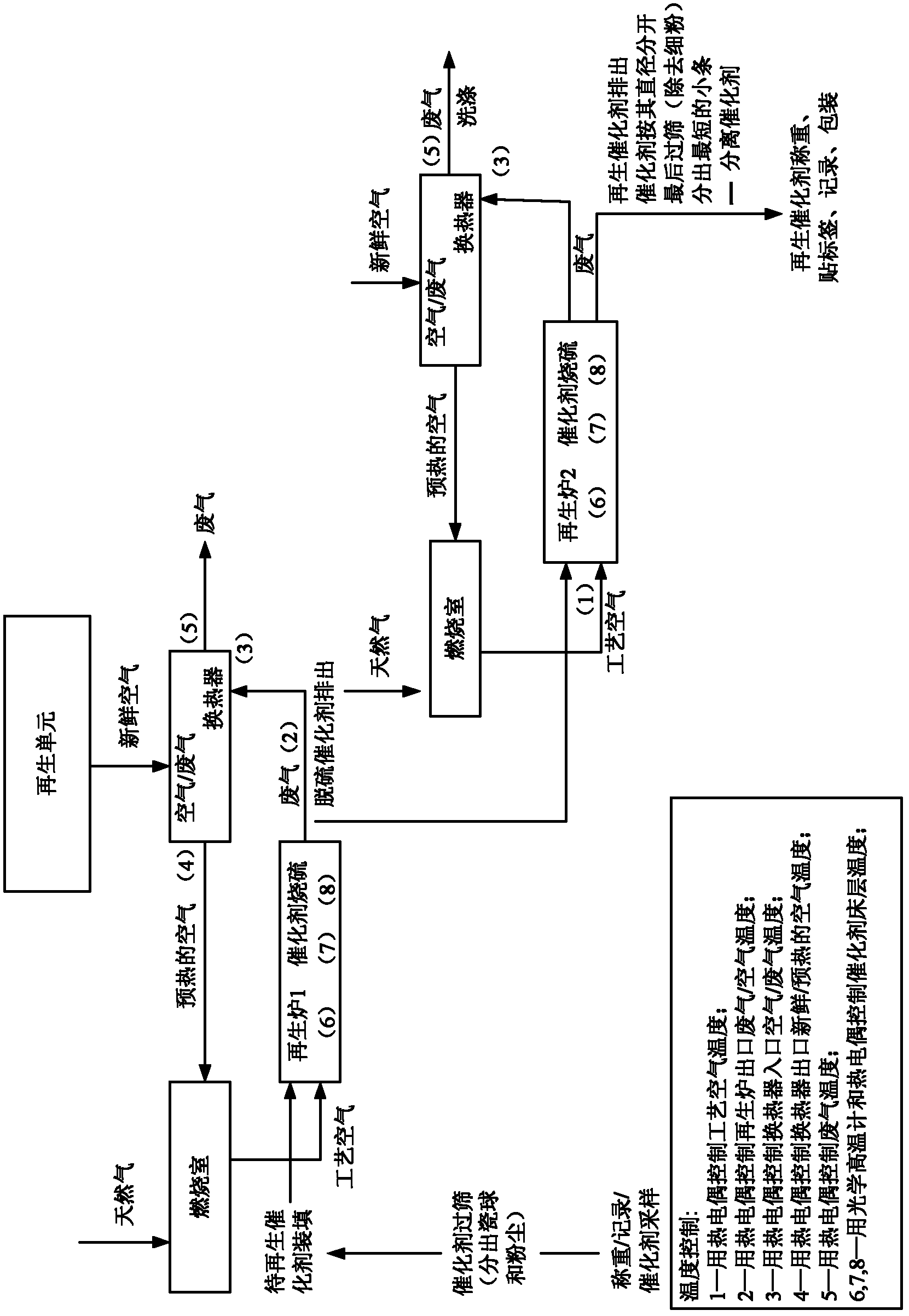

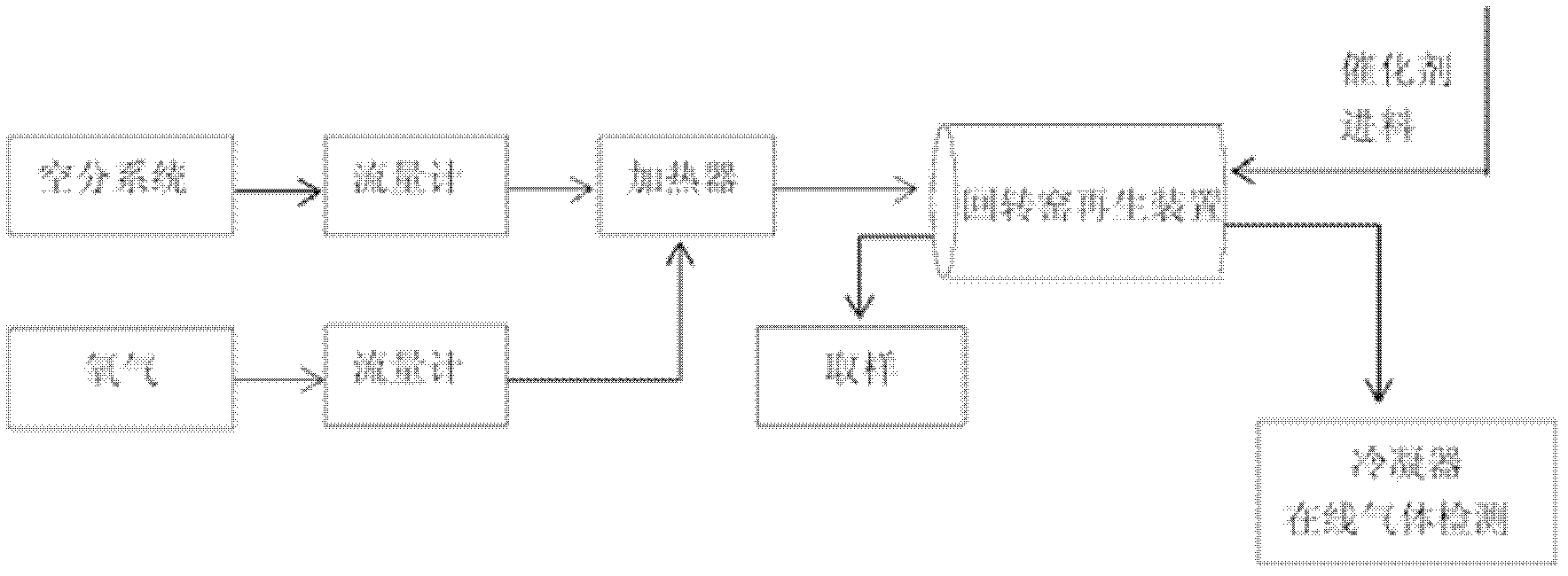

Method used

Image

Examples

Embodiment 1

[0077] The regeneration steps and parameters of regeneration catalyst A are as follows:

[0078] a0. In the stage of heating nitrogen with oil, the hydrogenation deactivated catalyst discharged from the T-Star fluidized bed is collected online, and the oil content on the surface of the catalyst is removed by means of heating nitrogen with oil, so that it can reach the conditions for regeneration. The process parameters of the hot nitrogen belt oil are: temperature 250-280°C, gas agent ratio of the hot nitrogen belt oil 300-400 / h (vol / vol), and reaction time 3-5 hours.

[0079] a. In the catalyst loading stage, according to the volume of the isothermal zone in the rotary kiln, the inactivated catalyst after deoiling is sieved and sent into the rotary kiln, and the deactivated catalyst is spread in the rotary kiln isothermal by the slow rotation of the rotary kiln. On the inner surface of the zone, the thickness of the catalyst is generally controlled at a thickness of 0.5-1.0cm...

Embodiment 2

[0098] The regeneration procedure of the regenerated catalyst B is consistent with that of the regenerated catalyst A, and the regeneration parameters are shown in Table 3. The activity of regenerated catalyst B under the same hydrogenation process parameters of coal liquefaction raw oil and direct coal liquefaction oil is shown in Table 7.

[0099] Table 3 Coking parameters of regenerated catalyst B

[0100]

Embodiment 3

[0102] The regeneration steps of the regenerated catalyst C are consistent with those of the regenerated catalyst A, and the regeneration parameters are shown in Table 4. The activity of regenerated catalyst C under the same hydrogenation process parameters of coal liquefaction feed oil and direct coal liquefaction oil is shown in Table 7.

[0103] Table 4 Coking parameters of regenerated catalyst C

[0104] Regeneration Phase Parameters

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com