TiCp/M2 high-speed steel composite material and SPS (spark plasma sintering) preparation method thereof

A technology of composite materials and high-speed steel, applied in the field of powder metallurgy, to achieve the effects of convenient operation, improved solubility and controllable content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

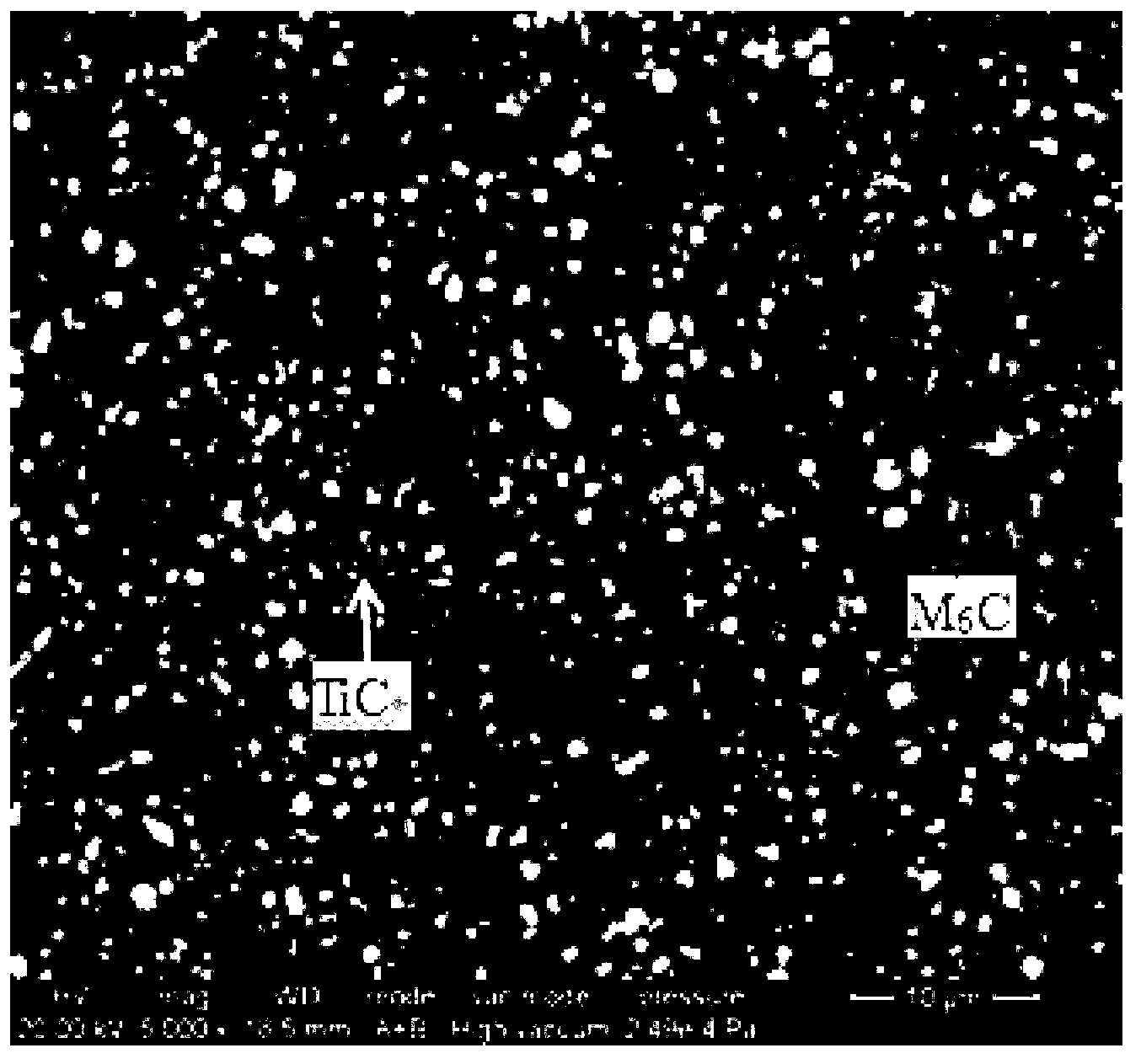

[0038] A kind of TiC prepared by SPS p The method for / M2 high-speed steel composite material comprises the following steps and process conditions thereof:

[0039] Step 1: Ingredients and Mixing

[0040] The M2 high-speed steel powder and TiC powder are proportioned according to the following volume percentages: M2 high-speed steel 95.00%, TiC 5.00%, and the powders are put into a V-shaped mixer for dry mixing for 2 hours.

[0041] The particle size of M2 high-speed steel is less than 147μm, and the components and their mass percentages are: C0.83%, Mn0.27%, Si0.32%, W5.12%, Mo5.00%, Cr3.13%, V1.97% , the balance is Fe, containing unavoidable trace impurities; the average particle size of TiC particles is 1-3 μm, and the purity is ≥99.5%.

[0042] Step 2: High energy ball milling

[0043] TiC after dry blending in step 1 p / M2 high-speed steel mixed powder is put into a planetary ball mill for high-energy ball milling. The material of the balls is stainless steel. The bal...

Embodiment 2

[0048] A kind of TiC prepared by SPS p The method for / M2 high-speed steel composite material comprises the following steps and process conditions thereof:

[0049] Step 1: Ingredients and Mixing

[0050] The M2 high-speed steel powder and TiC powder are proportioned according to the following volume percentages: M2 high-speed steel 95.00%, TiC 5.00%, and the powder is put into a V-shaped mixer for dry mixing for 6 hours.

[0051] The particle size of M2 high-speed steel is less than 147μm, and the components and their mass percentages are: C0.83%, Mn0.27%, Si0.32%, W5.12%, Mo5.00%, Cr3.13%, V1.97% , the balance is Fe, containing unavoidable trace impurities; the average particle size of TiC particles is 1-3 μm, and the purity is ≥99.5%.

[0052] Step 2: High energy ball milling

[0053] TiC after dry blending in step 1 p / M2 high-speed steel mixed powder is put into a planetary ball mill for high-energy ball milling. The material of the balls is stainless steel. The ball-...

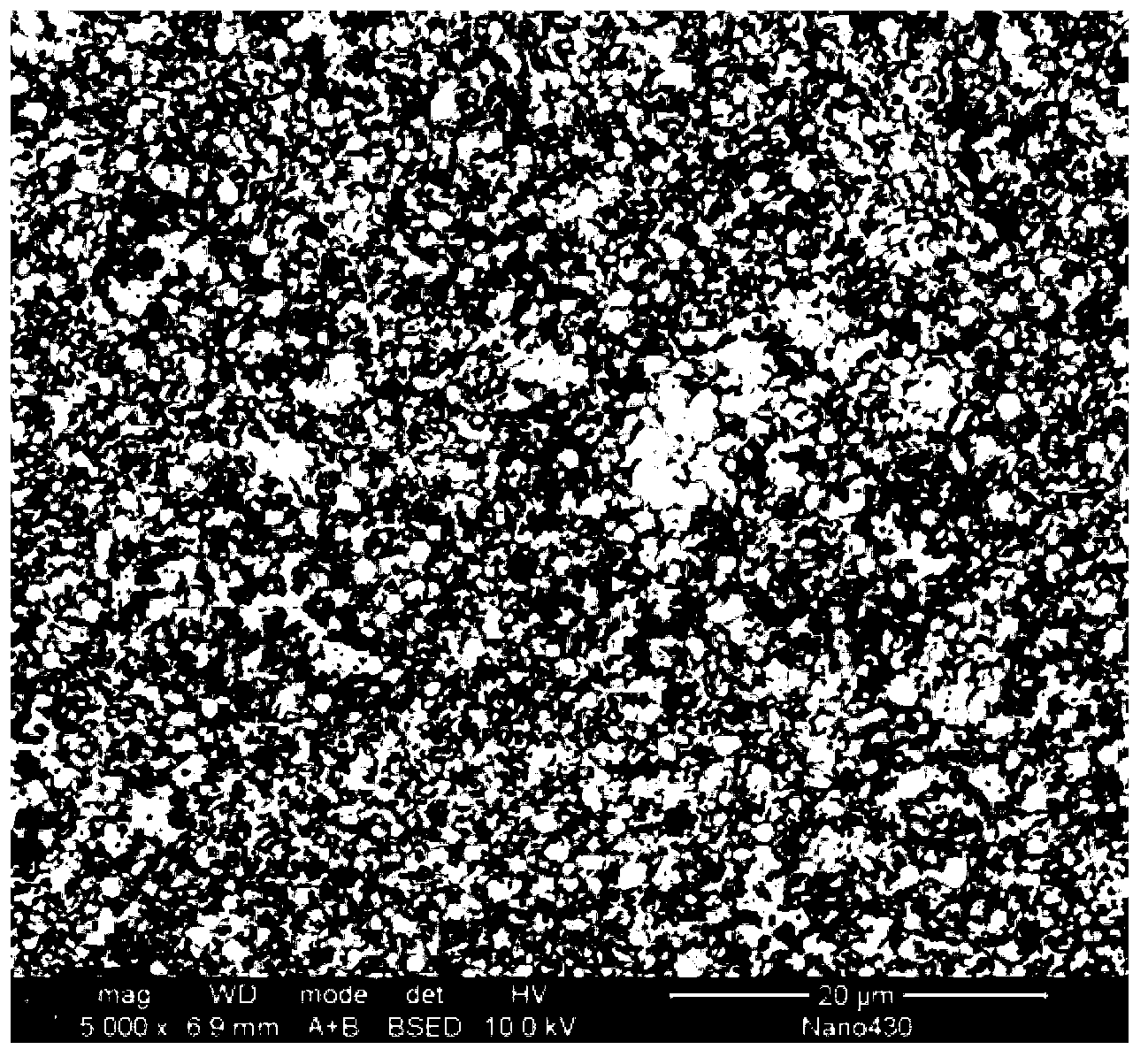

Embodiment 3

[0057] A kind of TiC prepared by SPS p The method for the / M2 high speed steel composite material comprises the following steps and process conditions thereof:

[0058] Step 1: Ingredients and Mixing

[0059] The M2 high-speed steel powder and TiC powder are proportioned according to the following volume percentages: M2 high-speed steel 90.00%, TiC 10.00%, and the powders are put into a V-shaped mixer for dry mixing for 12 hours.

[0060] The particle size of M2 high-speed steel is less than 147μm, and the components and their mass percentages are: C0.83%, Mn0.27%, Si0.32%, W5.12%, Mo5.00%, Cr3.13%, V1.97% , the balance is Fe, containing unavoidable trace impurities; the average particle size of TiC particles is 1-3 μm, and the purity is ≥99.5%.

[0061] Step 2: High energy ball milling

[0062] TiC after dry blending in step 1 p / M2 high-speed steel mixed powder is put into a planetary ball mill for high-energy ball milling. The material of the balls is stainless steel. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com