Manufacturing device and manufacturing method for hot-rolled steel strip

A technology for manufacturing devices and manufacturing methods, which is applied in the field of manufacturing devices for hot-rolled steel strips, can solve problems such as different fields, poor yields, and elongated lengths, and achieve the effect of small uneven cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

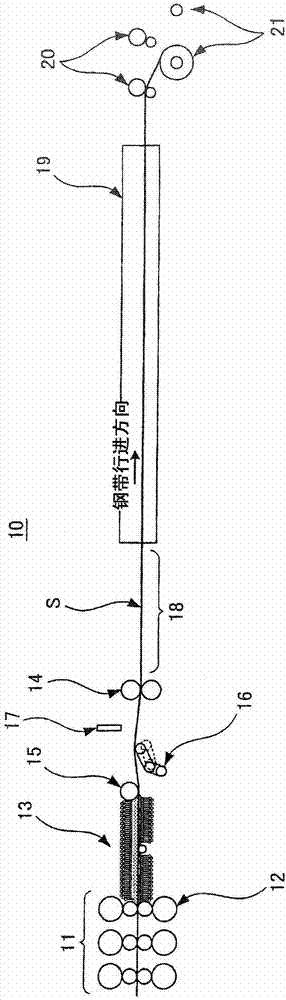

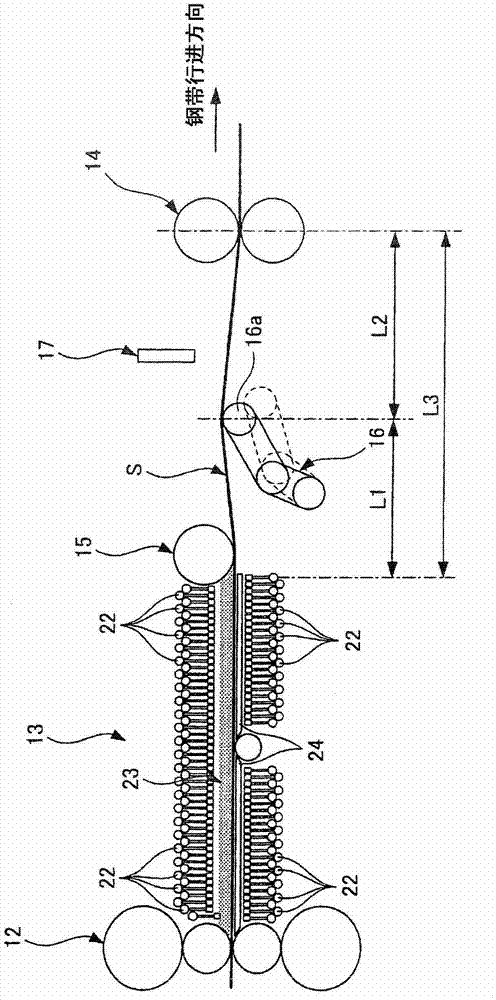

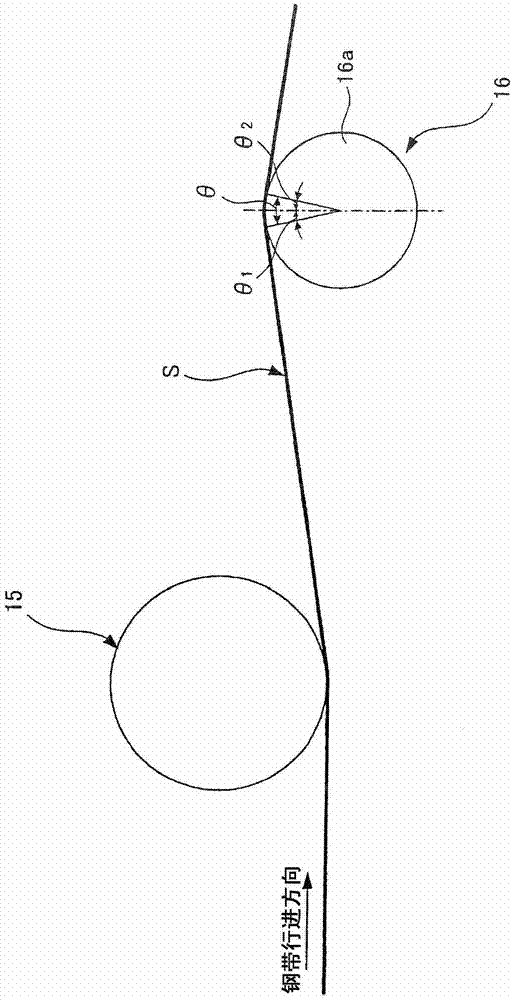

[0064] figure 1 is an overall configuration diagram showing a hot rolling facility according to Embodiment 1 of the present invention, figure 2 It indicates the installation position of the sheet tension and sheet shape measuring device figure 1 The enlarged view of the main part, image 3 It indicates the winding angle of the sheet tension and sheet shape measuring device figure 1 The enlarged view of the main part, Figure 4A and Figure 4B is each characteristic diagram in the shape control of the final stand of the finishing mill row, Figure 5A It is based on the calculation model and each relationship diagram of Non-Patent Document 1, Figure 5B It is each relationship diagram based on Non-Patent Document 1.

[0065] Such as figure 1 As shown, the hot rolling equipment 10 is equipped with the first cooling device 13 arranged next to the output side of the final stand 12 of the finishing mill train 11, arranged on the output side of the first cooling device 13 and...

Embodiment 2

[0096] Image 6 It is an enlarged view of main parts showing a hot rolling facility according to Example 2 of the present invention.

[0097] This embodiment 2 is to change the tension / shape measuring device 16 in embodiment 1 into only the tension measuring device 16A and pass through the air cooling zone 18 (refer to figure 1 ) in the shape measurement mechanism to perform shape measurement example. This tension measuring device 16A is a device in which a load cell is built in the bearing portions at both ends of a continuous undivided roll 16a, and a force is applied to the lower surface of the steel strip S by a pantograph mechanism or the like. In this way, the tension of the entire strip S is measured.

[0098] In addition, the shape measurement mechanism in the air cooling zone 18 is a sheet shape measurement method for observing the appearance shape of the hot-rolled steel strip, and it does not work until the front end of the strip S is wound by the down coiler 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com