Carbon supported core-shell structure nano metal catalyst as well as preparation method and application thereof

A core-shell structure, nano-metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc. In order to achieve the effect of good catalytic hydrogenation performance, improved structural stability, and improved chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

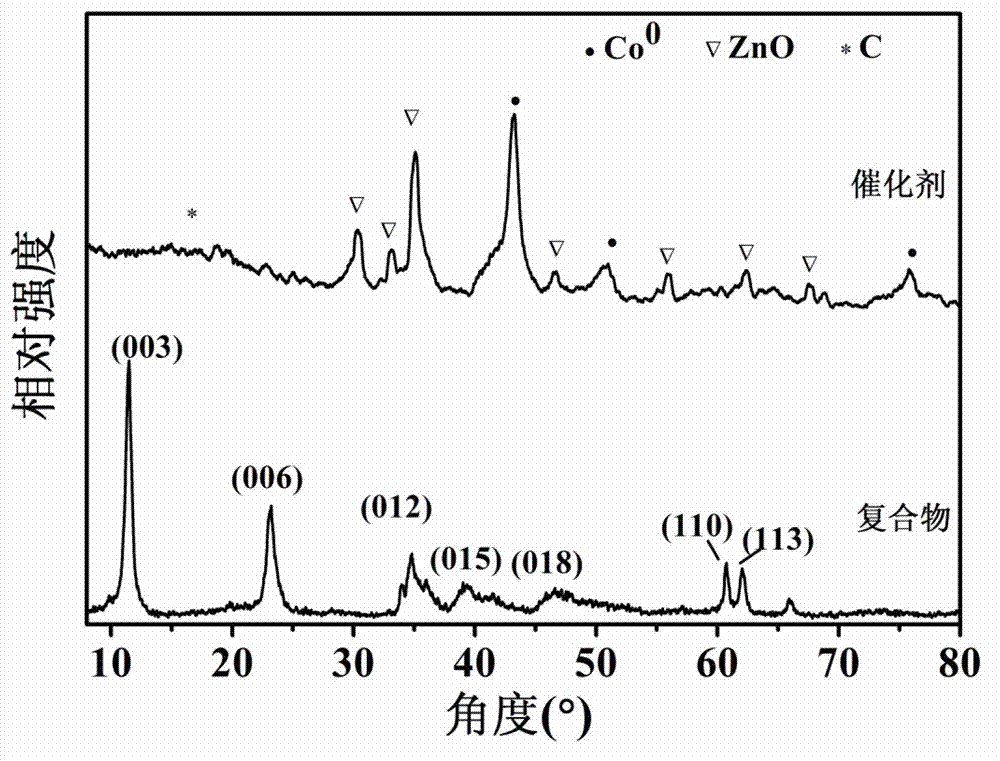

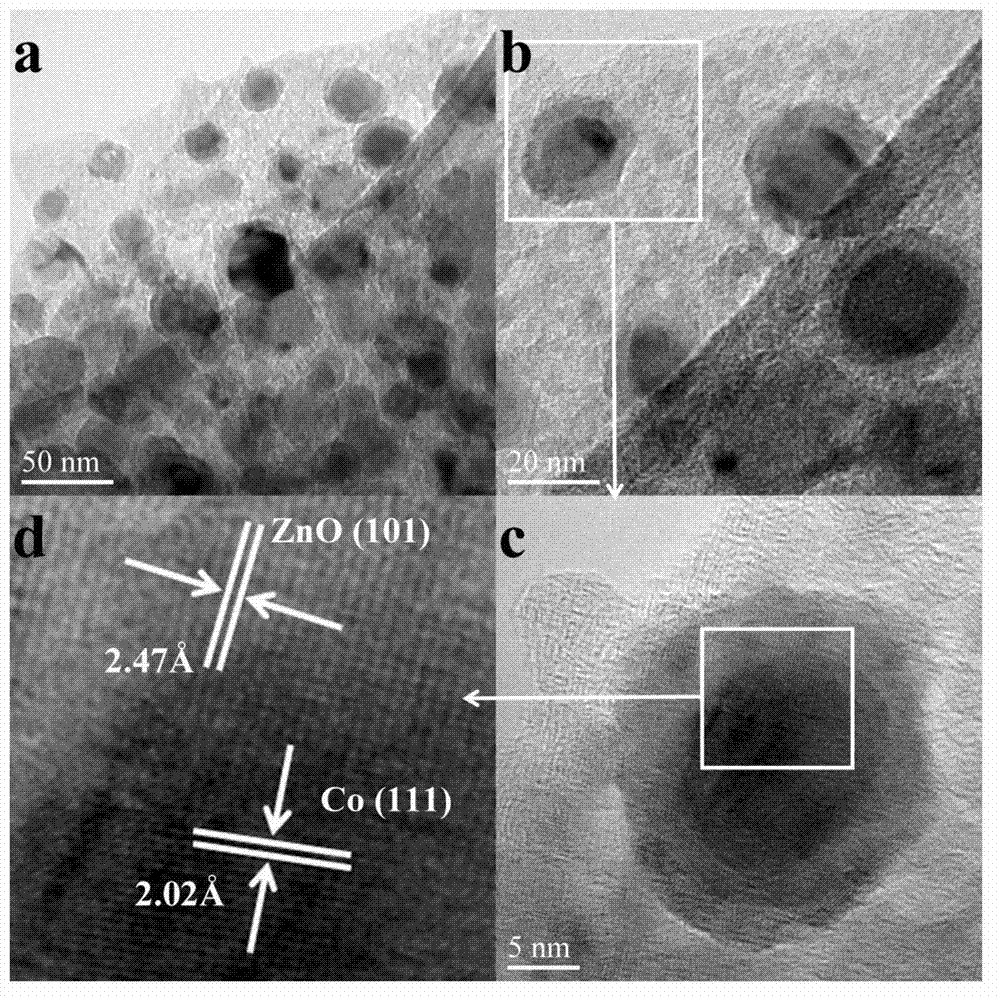

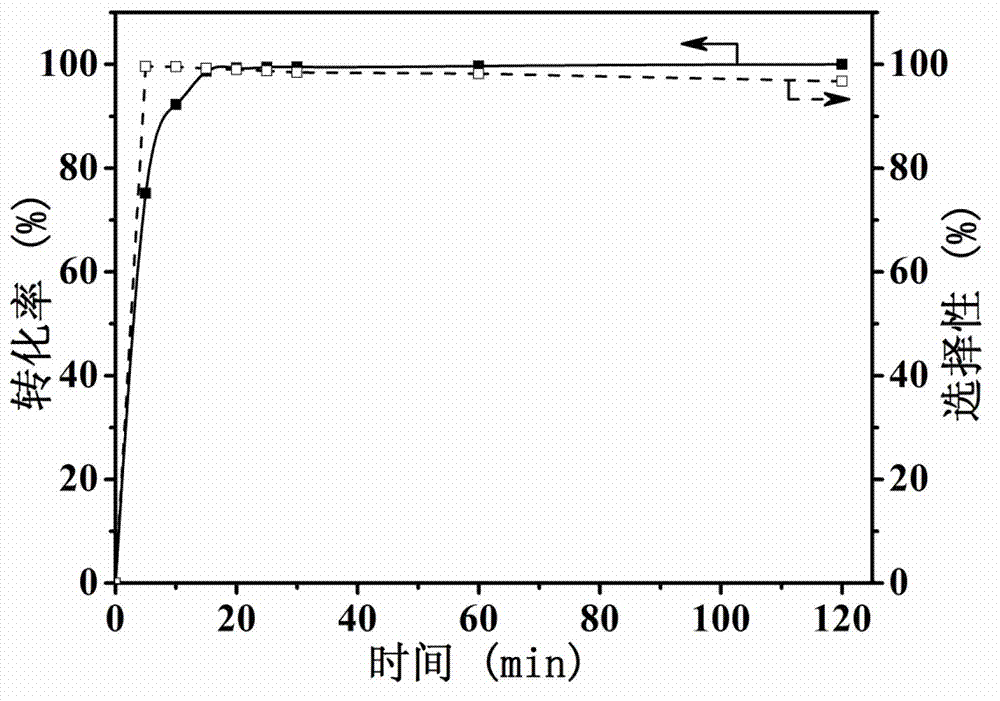

[0021] 0.006mol (CH 3 COO) 2 Co 4H 2 O, 0.006mol (CH 3 COO) 2 Zn·2H2 O, 0.003mol Al(NO 3 ) 3 9H 2 O was dissolved in 30ml deionized water as solution A. Another 0.024mol NaOH, 0.0075mol CH 3 COONa was dissolved in 30ml deionized water as solution B. Slowly pour solution A and solution B into the colloid mill (4000rpm), fully stir and mix for 3 minutes, centrifuge the slurry and wash it 3 times to make it neutral, fully disperse the slurry in 60ml deionized water, transfer to 80ml poly Crystallized at 140°C for 8 hours in a vinyl fluoride reactor, then centrifuged and washed to obtain CoZnAl-LDH. The obtained CoZnAl-LDH slurry and 0.00225mol β-cyclodextrin were dispersed in 100ml deionized water at 80°C and stirred until all the water evaporated to obtain a CoZnAl-LDH / β-cyclodextrin complex.

[0022] The CoZnAl-LDH / β-cyclodextrin complex prepared above was placed in a tube atmosphere furnace under N 2 Under the atmosphere (60mL / min), the temperature was raised to 200...

Embodiment 2

[0025] 0.009mol (CH 3 COO) 2 Co 4H 2 O, 0.003mol (CH 3 COO) 2 Zn·2H 2 O, 0.003mol Al(NO 3 ) 3 9H 2 O was dissolved in 30ml deionized water as solution A. Another 0.02mol NaOH, 0.005mol CH 3 COONa was dissolved in 30ml deionized water as solution B. Slowly pour solution A and solution B into the colloid mill (4000rpm), fully stir and mix for 3 minutes, centrifuge the slurry and wash it 3 times to make it neutral, fully disperse the slurry in 60ml deionized water, transfer to 80ml poly Crystallized at 170°C for 6 hours in a vinyl fluoride reactor, then centrifuged and washed to obtain CoZnAl-LDH. The obtained CoZnAl-LDH slurry and 0.00225mol β-cyclodextrin were dispersed in 100ml deionized water at 80°C and stirred until all the water evaporated to obtain a CoZnAl-LDH / β-cyclodextrin complex.

[0026] The CoZnAl-LDH / β-cyclodextrin complex prepared above was placed in a tube atmosphere furnace under N 2 Under the atmosphere (80mL / min), the temperature was raised to 250...

Embodiment 3

[0029] 0.003mol (CH 3 COO) 2 Co 4H 2 O, 0.009mol (CH 3 COO) 2 Zn·2H 2 O, 0.003mol Al(NO 3 ) 3 9H 2 O was dissolved in 30ml deionized water as solution A. Another 0.024mol NaOH, 0.005mol CH 3 COONa was dissolved in 30ml deionized water as solution B. Slowly pour solution A and solution B into the colloid mill (4000rpm), fully stir and mix for 6 minutes, centrifuge the slurry and wash it 3 times to make it neutral, fully disperse the slurry in 60ml deionized water, transfer to 80ml poly Crystallized at 150°C for 10 hours in a vinyl fluoride reactor, then centrifuged and washed to obtain CoZnAl-LDH. The obtained CoZnAl-LDH slurry and 0.0015mol β-cyclodextrin were dispersed in 100ml deionized water at 80°C and stirred until all the water evaporated to obtain a CoZnAl-LDH / β-cyclodextrin complex.

[0030] The CoZnAl-LDH / β-cyclodextrin complex prepared above was placed in a tube atmosphere furnace under N 2 Under the atmosphere (100mL / min), the temperature was raised to 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com