Method for measuring vibration performance of tool nose of micro-milling tool

A vibration characteristic, micro-milling technology, applied in measuring/indicating equipment, manufacturing tools, metal processing machinery parts, etc., can solve the problems of insufficient research scope, simple model, poor practicability, etc. Promising and easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

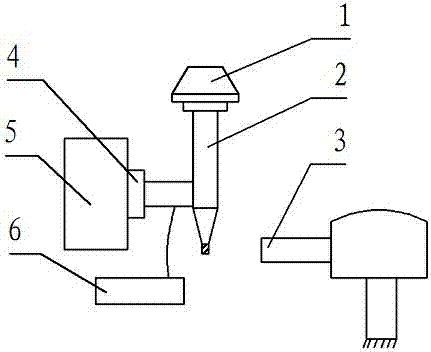

[0018] Such as figure 1 As shown, the present invention is a method for measuring the vibration characteristics of the tip of a micro-milling tool.

[0019] 1. Clamp a micro milling cutter with a head diameter of 0.5mm (length 2mm) and a shank diameter of 3mm (length 15mm) in the tool holder of the high-speed spindle.

[0020] 2. One end of the piezoelectric driver (section 3mm×3mm, length 8mm) is glued to the handle of the micro-milling cutter, and the other end is connected to a high-frequency force sensor (natural frequency 200kHz) glued to the motion platform of the machine tool.

[0021] 3. The machine tool drives the micro-milling cutter to feed the piezoelectric actuator in a small amount, and a pre-pressure of 20N is applied between the piezoelectric actuator and the tool holder.

[0022] 4. Use an external signal generator with a frequency range of 1kHz-150kHz to give sinusoidal excitation to the piezoelectric actuator.

[0023] 5. Using laser Doppler vibrometer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com