Hybrid-electric pure electric vehicle energy distributor and control method thereof

A technology of pure electric vehicles and distributors, applied in electric vehicles, secondary battery charging/discharging, collectors, etc., can solve the problems of reduced power supply cycle life, affecting driving safety, long switching time, etc., to overcome frequent switching The effect of high failure rate, simple connection method and fast working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings:

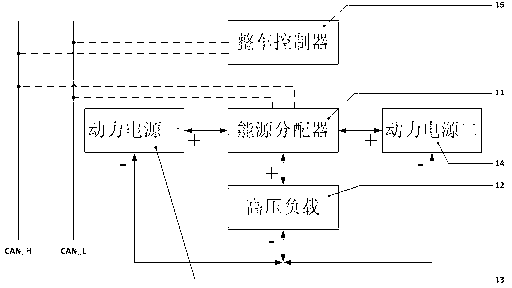

[0028] Take the energy distributor of an electric-electric hybrid pure electric vehicle containing two power sources as an example.

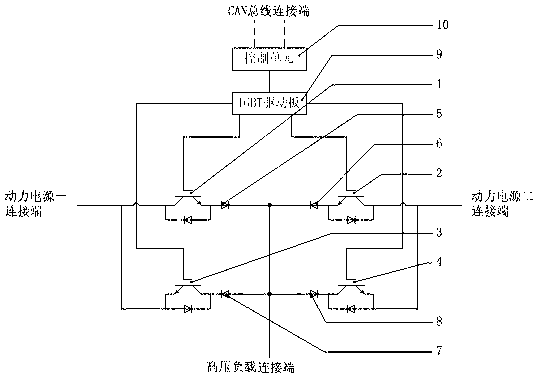

[0029] Such as figure 2 The shown electric-electric hybrid pure electric vehicle energy distributor includes two pairs of IGBTs (the first pair is composed of IGBT1 and IGBT3, and the second pair is composed of IGBT2 and IGBT4), an IGBT drive board 9 and a control unit 10. The collector of the first IGBT1 of the first pair of IGBT1, 3 is connected to the emitter of the second IGBT3, and the connecting terminal is drawn at the connection point, which serves as the power supply connection terminal of the energy distributor; the first pair of IGBT1, 3 The emitter of IGBT1 is connected to the anode of one diode 5, the collector of the second IGBT3 is connected to the cathode of the other diode 7, and the other poles of the two diodes 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com