Composite flake heavy-duty coating for ocean storage and transportation facilities

A technology for composite fillers and facilities, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., and can solve the difficulties of ensuring the final quality of anti-corrosion layer construction, increasing the difficulty of on-site management and logistics materials, and many changes in process construction conditions, etc. problems, to achieve the effect of facilitating large-scale production and application, protecting non-metallic structures, and excellent anti-corrosion performance

Active Publication Date: 2015-07-22

柳州贝丽嘉涂料有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the diverse characteristics of the application of anti-corrosion coatings in the structure of marine storage and transportation facilities, there are strong specificity, many varieties, high construction technology requirements, and many changes in process construction conditions, which are likely to cause different construction process requirements for various structural parts, increasing On-site management and logistics materials are difficult, and it is not easy to guarantee the final quality of the construction of various anti-corrosion layers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

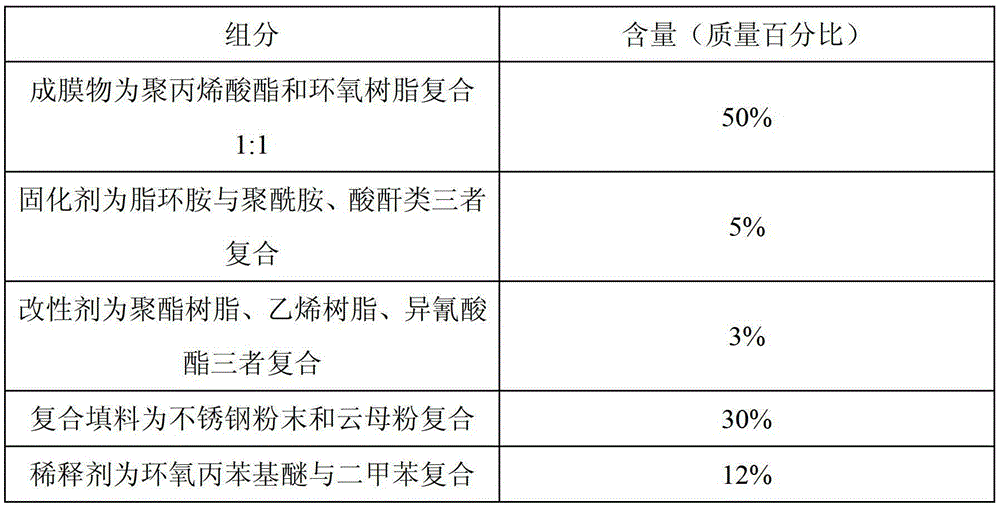

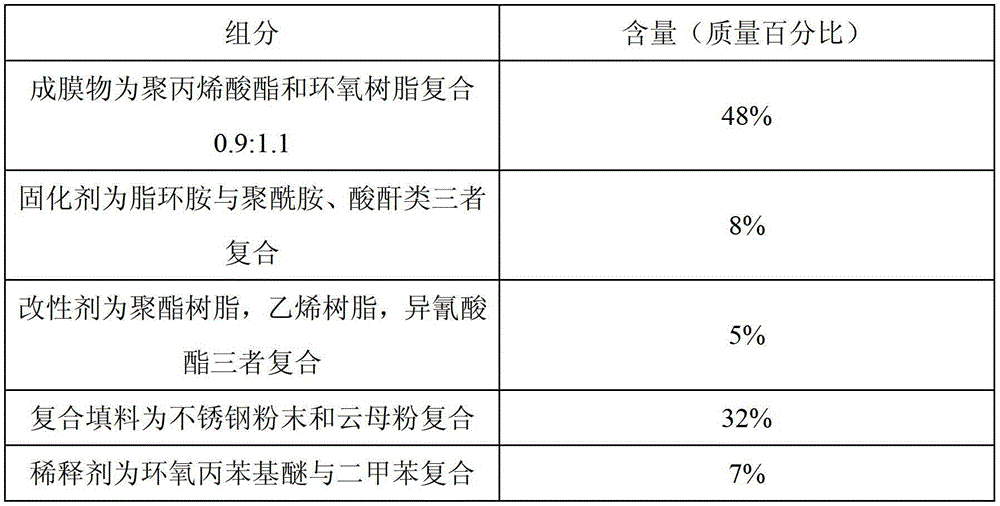

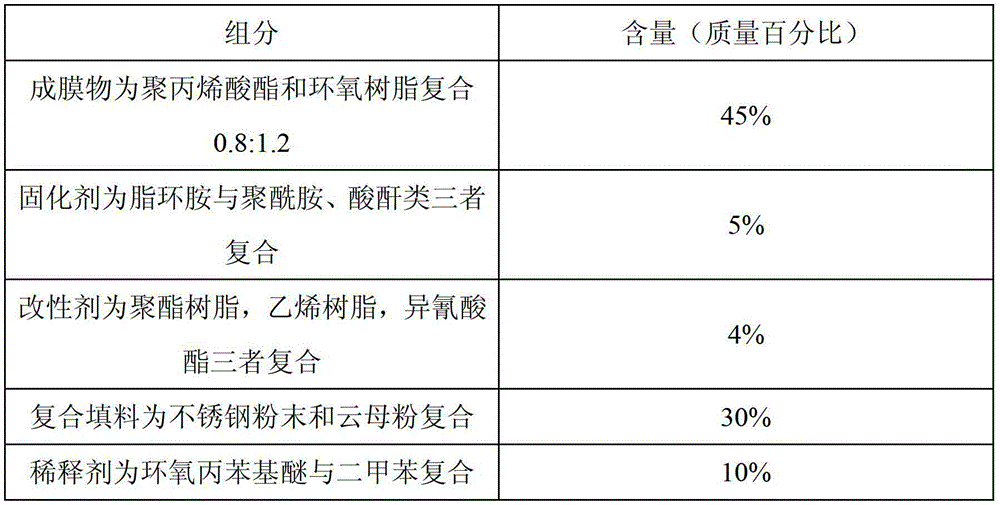

[0023] Embodiment 3: component and mass percent are:

[0024]

[0025] The basic performance index of the coating of embodiment 1 is:

[0026] detection item

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a composite flake heavy-duty coating for ocean storage and transportation facilities. The coating comprises the following ingredients in percentage by mass: 40-60% of film former, 2-10% of curing agent, 3-8% of modifying agent, 30-40% of composite filling, and more than 0 but less than 15% of diluent. The coating has an interpenetrating polymer network (IPN) structure, is wide in raw material resources, simple in conditioning technology and conductive to large-scale production and application, and the specifically modified coating is conductive to outdoor field construction. The composite flake heavy-duty coating is strong in adhesion, excellent in corrosion resistance, and suitable for application in oceanographic engineering and wild working condition, not only can protect a metal structure, but also can protect a nonmetallic structure.

Description

technical field [0001] The invention relates to a composite scale heavy-duty coating used in marine storage and transportation facilities. Background technique [0002] Corrosion involves almost all areas of the national economy, not only causing huge losses, but also hindering the development of new technologies and processes. There are usually two measures for corrosion control: one is remedial measures, which eliminate corrosion after it occurs; the other is preventive measures, that is, measures to prevent corrosion are taken in advance to avoid or delay corrosion. The practice of anti-corrosion shows that anti-corrosion coating is the most effective, most economical and most widely used method. Due to the continuous emergence of large-scale marine projects and the improvement of the application conditions of chemical engineering for the construction of anti-corrosion coatings, the requirements for adapting to harsh working conditions are constantly facing severe challe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D133/08C09D163/00C09D5/10C09D7/12

Inventor 黄福川粟满荣卢朝霞莫宇飞梁景唐兴中唐彩珍蓝明新李宏君肖友程李胜梁慧田宗义赵钟兴唐丹葵刘琨

Owner 柳州贝丽嘉涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com