Preparation method for SiO2-based organic-inorganic hybridized fluorescent material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

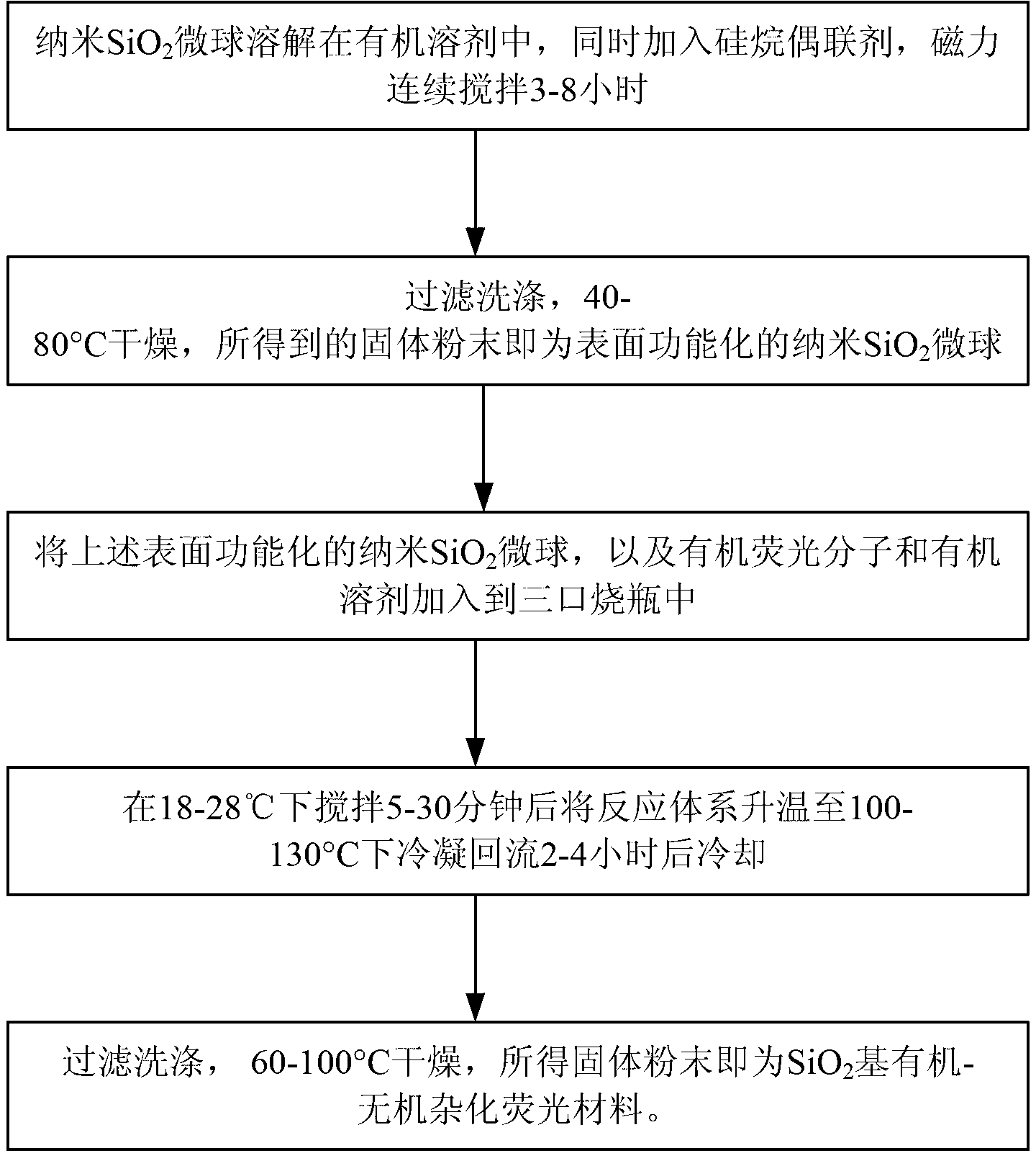

[0024] A SiO 2 The preparation method of based organic-inorganic hybrid fluorescent material, such as figure 1 shown, including the following steps:

[0025] 1): dense nano-SiO 2 Functionalization of microspheres

[0026] nano-SiO 2 Dissolve the microspheres in an organic solvent, add a silane coupling agent at the same time, continuously magnetically stir for 3-8 hours, filter and wash, and dry at 40-80°C. The obtained solid powder is the surface-functionalized nano-SiO 2 Microspheres;

[0027] 2): Preparation of organic-inorganic hybrid fluorescent materials

[0028] The above surface functionalized nano-SiO 2 Add microspheres, organic fluorescent molecules and organic solvents into a three-necked flask, stir at 18-28°C for 5-30 minutes, then raise the temperature of the reaction system to 100-130°C, condense and reflux for 2-4 hours, then cool the solution through Filter and wash, dry at 60-100°C, the resulting solid powder is SiO 2 based organic-inorganic hybrid fl...

Embodiment 2

[0031] At 25 °C, 0.25 g nano-SiO 2 The microspheres were dissolved in 25 mL of tetrahydrofuran solution, while 0.293 mL of 3-aminopropyltriethoxysilane was added, and stirring was continued for 5 hours. The resulting solution was then filtered, washed, and dried at 80°C for 4 hours to obtain surface-functionalized nano-SiO 2 The microspheres are designated as sample S-1.

[0032] 0.25g of the above-mentioned sample S-1, and 0.025g of 4-amino-1,8-naphthalene dioic anhydride and 25mL of N,N-dimethylformamide were simultaneously added to a 100mL three-necked flask, and stirred at 25°C for 5 Minutes later, the temperature was raised to 130° C. and condensed and refluxed for 3 hours, then the reaction solution was cooled, filtered, washed, and dried at 100° C. for 4 hours to obtain SiO 2 based organic-inorganic hybrid materials.

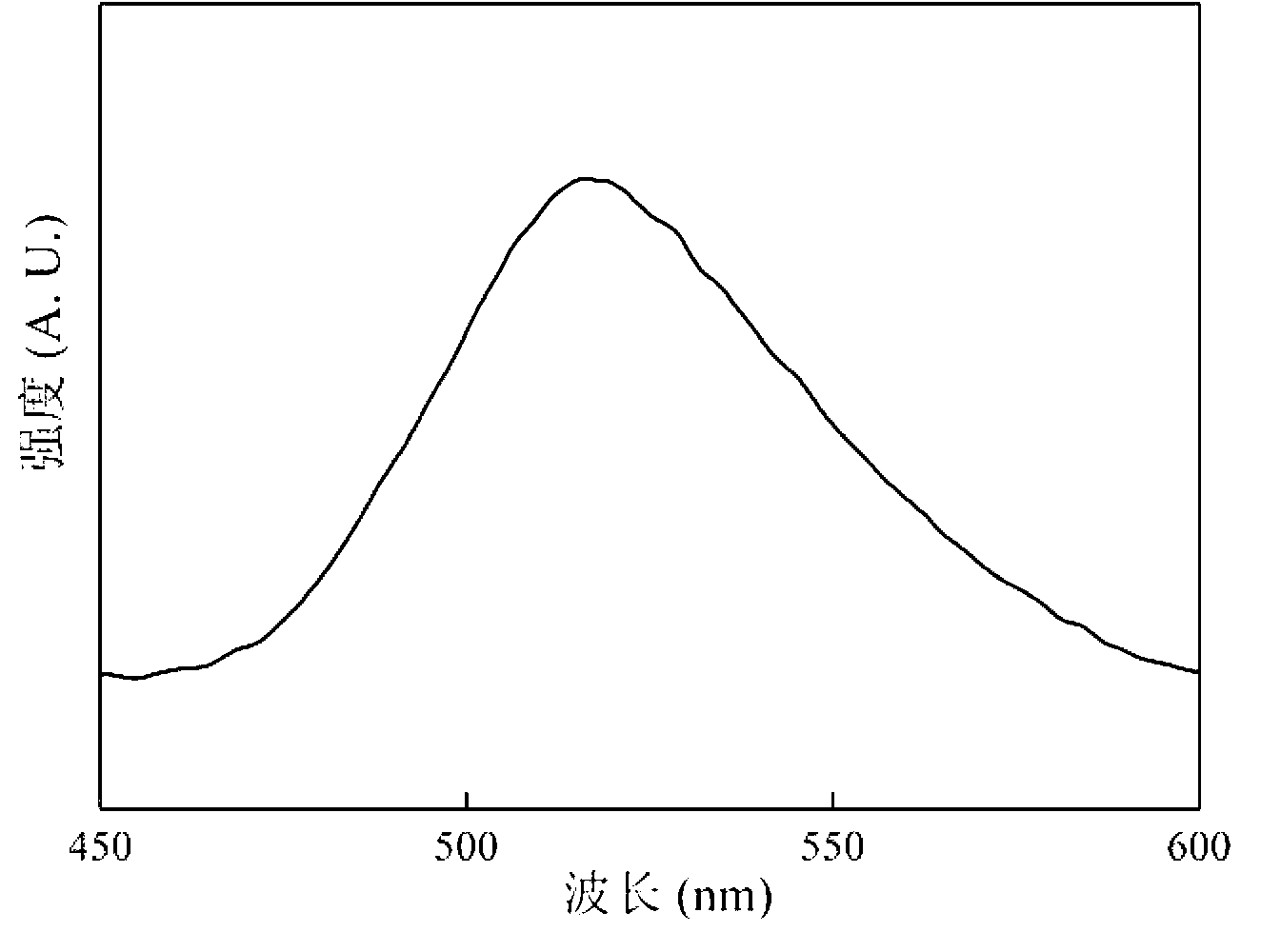

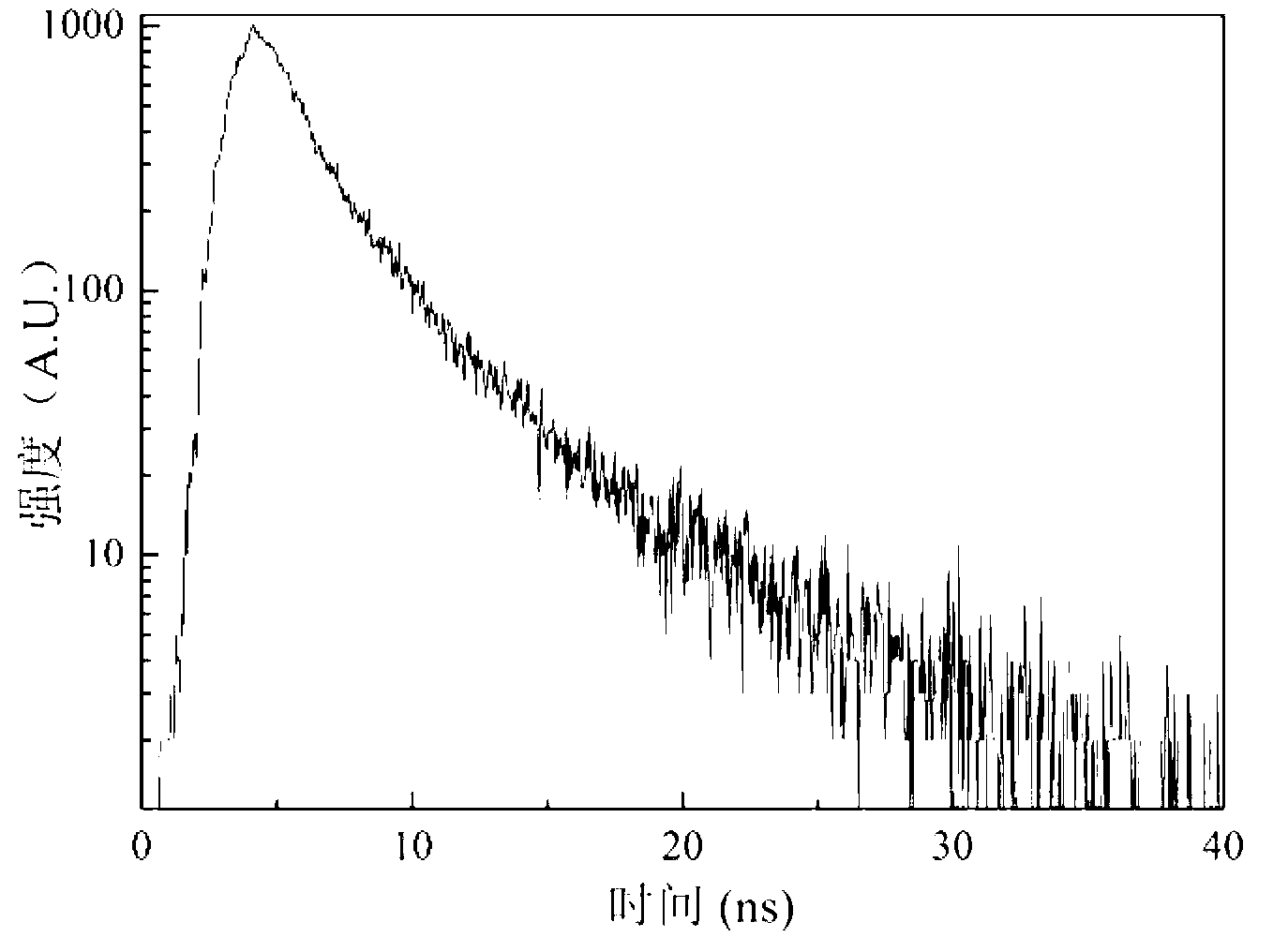

[0033] For the SiO obtained in this experiment 2 Fluorescence spectrum and time-resolved fluorescence spectrum analysis of fluorescent molecules when...

Embodiment 3

[0035] First, SiO with a diameter of 10 nm 2 The microspheres were dried at 150 °C for 5 h and cooled to room temperature under airtight conditions. At 18 °C, 0.25 g nano-SiO 2 The microspheres were dissolved in 10 mL of tetrahydrofuran solution, while 0.1772 mL of thiopropylmethyldimethoxysilane was added, and stirring was continued for 3 hours. Subsequently, the resulting solution was filtered and washed, and dried at 40°C for 4 hours to obtain surface-functionalized nano-SiO 2 The microspheres are designated as sample S-2.

[0036] Add 0.25g of the above sample S-2, and 0.00025g of 4-amino-1,8-naphthalene dioic anhydride and 10mL of N,N-dimethylformamide into a 100mL three-necked flask at the same time, and stir at 18°C After 15 minutes, the temperature was raised to 100°C for condensing and reflux for 2 hours, then the reaction solution was cooled, filtered, washed, and dried at 60°C for 4 hours to obtain SiO 2 based organic-inorganic hybrid materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com