Stirring-type and air-lifting combined bioreactor and application thereof in preparing rhamnose gum

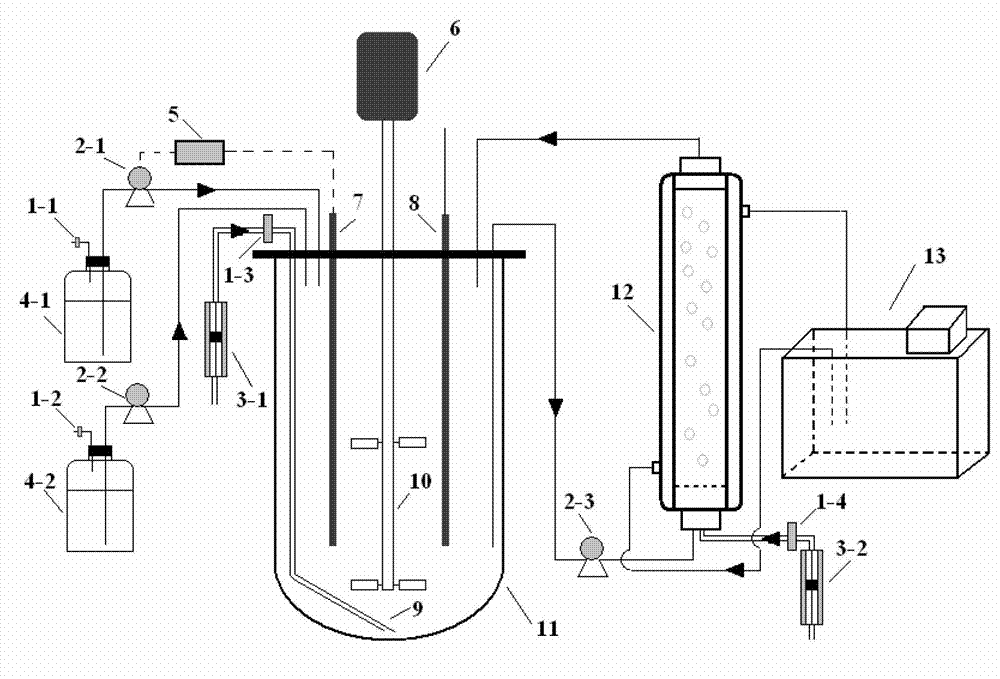

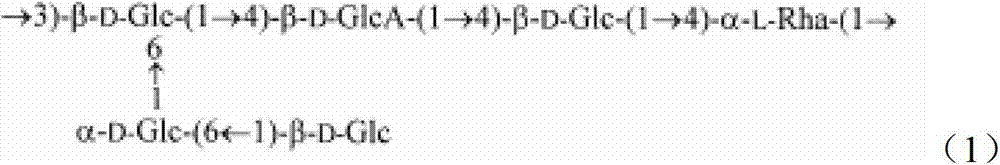

A technology of stirred reactor and airlift reactor, which is applied in the application field of rhamnose gum preparation, can solve the problems of unseen fermentation research and industrial production reports, and achieve the improvement of mass transfer rate and dissolved oxygen level , small shear force, and the effect of reducing the apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: A 3L stirred reactor used glucose as a carbon source to produce rhamnose gum in a single batch of free cell fermentation (no airlift reactor).

[0032] Using glucose as carbon source, rhamnan gum was produced by single-batch fermentation of free cells of Sphingomonas sp.RH-1 (CGMCC NO.6833), which has been patented by our laboratory.

[0033] Seed medium: glucose 10g / L, beef extract 3g / L, peptone 5g / L, MgSO 4 ·7H 2 O 0.5g / L, use NaOH solution to adjust the pH to 6.8.

[0034] Fermentation medium: glucose 40g / L, yeast extract 5g / L, (NH 4 ) 2 SO 4 5g / L, K 2 HPO 4 ·3H 2 O 2g / L, MgSO 4 ·7H 2 O 0.5g / L, use NaOH solution to adjust the pH to 6.8.

[0035] Scrape the strains on the slant of fresh Sphingomonas sp.RH-1, inoculate them in fresh seed medium, and cultivate them under the condition of 30°C and 200r / min shaker for 18h, and the seed solution is 8% (v / v) Inoculate in a 3L stirred reactor 11 pre-installed with 2.1L sterilized fermentation medium fo...

Embodiment 2

[0036] Example 2: A 3L stirred and air-lift bioreactor used glucose as a carbon source for single-batch fermentation to produce rhamnose gum.

[0037] Bacterial strain, seed culture medium and fermentation medium are the same as embodiment 1.

[0038] Scrape the strains on the slant of fresh Sphingomonas sp.RH-1, inoculate them in fresh seed medium, and cultivate them under the condition of 30°C and 200r / min shaker for 18h, and the seed solution is 8% (v / v) Inoculate in a 3L stirred reactor 11 pre-installed with 2.6L sterilized fermentation medium for cultivation, turn on the constant flow pump 2-3 to realize the material exchange in the stirred reactor 11 and the airlift reactor 12, Turn on the constant temperature water bath 13 to realize that the temperature of the material in the airlift reactor 12 is constant at 30°C. The reaction conditions of the stirred reactor are: 30°C, 600r / min, and the ventilation rate is 2.3L / min. During the fermentation process, the pH automatic ...

Embodiment 3

[0039] Example 3: Multi-batch fermentation of rhamnose gum by using glucose as a carbon source in a 3L stirred and air-lift bioreactor.

[0040] Bacterial strain, seed culture medium and fermentation medium are the same as embodiment 1.

[0041] Scrape the strains on the slant of fresh Sphingomonas sp.RH-1, inoculate them in fresh seed medium, and cultivate them under the conditions of 30°C and 200r / min shaker for 18h, and the seed solution is 10% (v / v) of the seed amount Inoculate in a 3L stirred reactor 11 pre-installed with 2.6L sterilized fermentation medium for cultivation, turn on the constant flow pump 2-3 to realize the material exchange in the stirred reactor 11 and the airlift reactor 12, Turn on the constant temperature water bath 13 to realize that the temperature of the material in the airlift reactor 12 is constant at 32°C. The reaction conditions of the stirred reactor are: 32°C, 1000r / min, and the ventilation rate is 2.3L / min. During the fermentation process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com