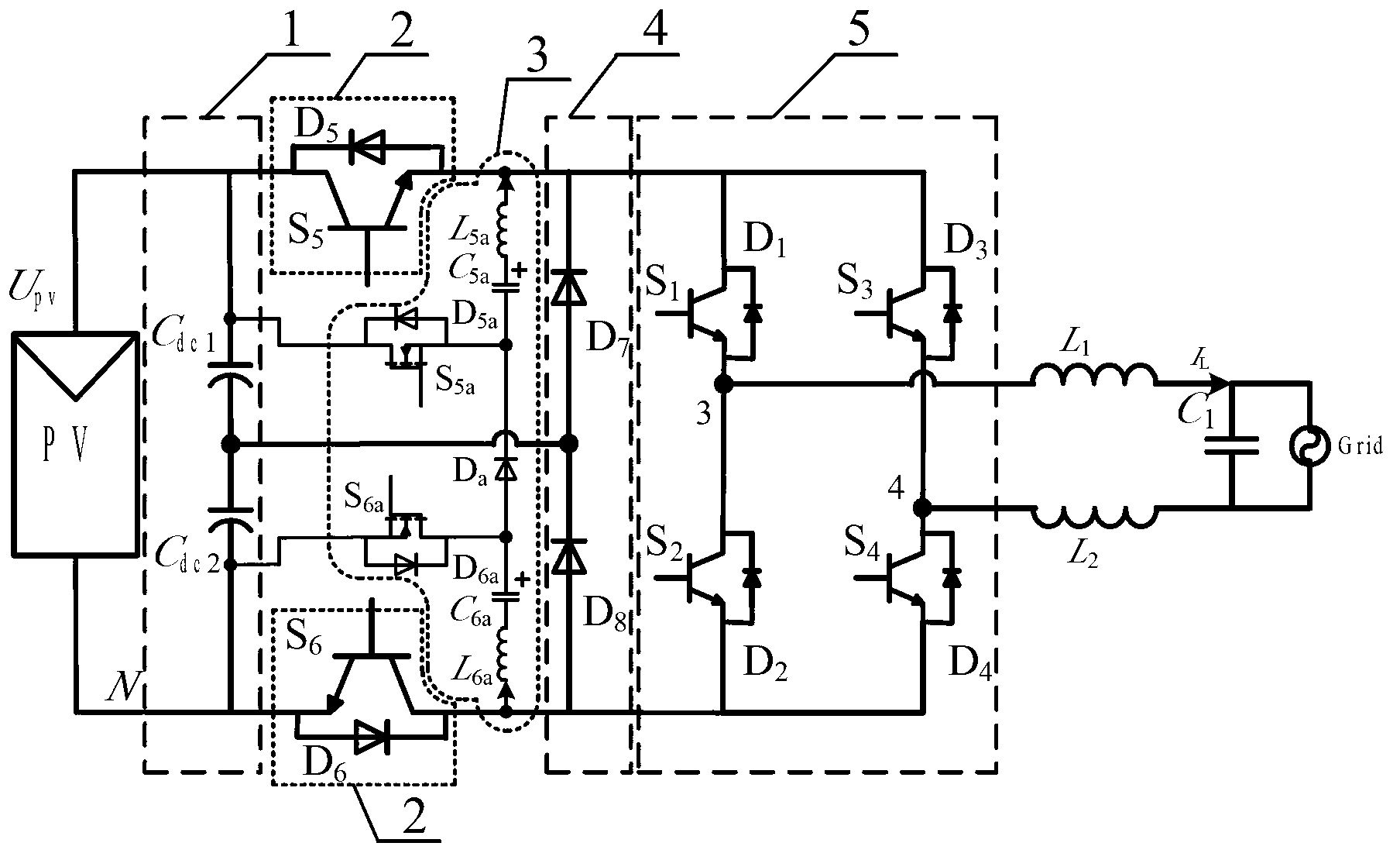

Zero current switching full-bridge type non-isolated photovoltaic grid-connected inverter

A non-isolated, zero-current technology, applied in the field of soft switching, can solve the problems of increased switching loss, decreased inverter efficiency, increased cost, etc., to achieve the effect of eliminating leakage current and achieving high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0052] A specific example of the present invention is as follows: battery plate voltage U pv =400V, grid voltage U grid =220VRMS, grid frequency f grid =50Hz, rated power P N =3kW; DC bus capacitance C dc1 =C dc2 =470μF; filter inductance L 1 = L 2 =0.5mH; filter capacitor C 1 =6μF; the parasitic capacitance of the battery board to the ground C pv1 = C pv2 =0.15μF; switching frequency f =50kHZ, resonance parameters L r =1.2μH, C r =765nF.

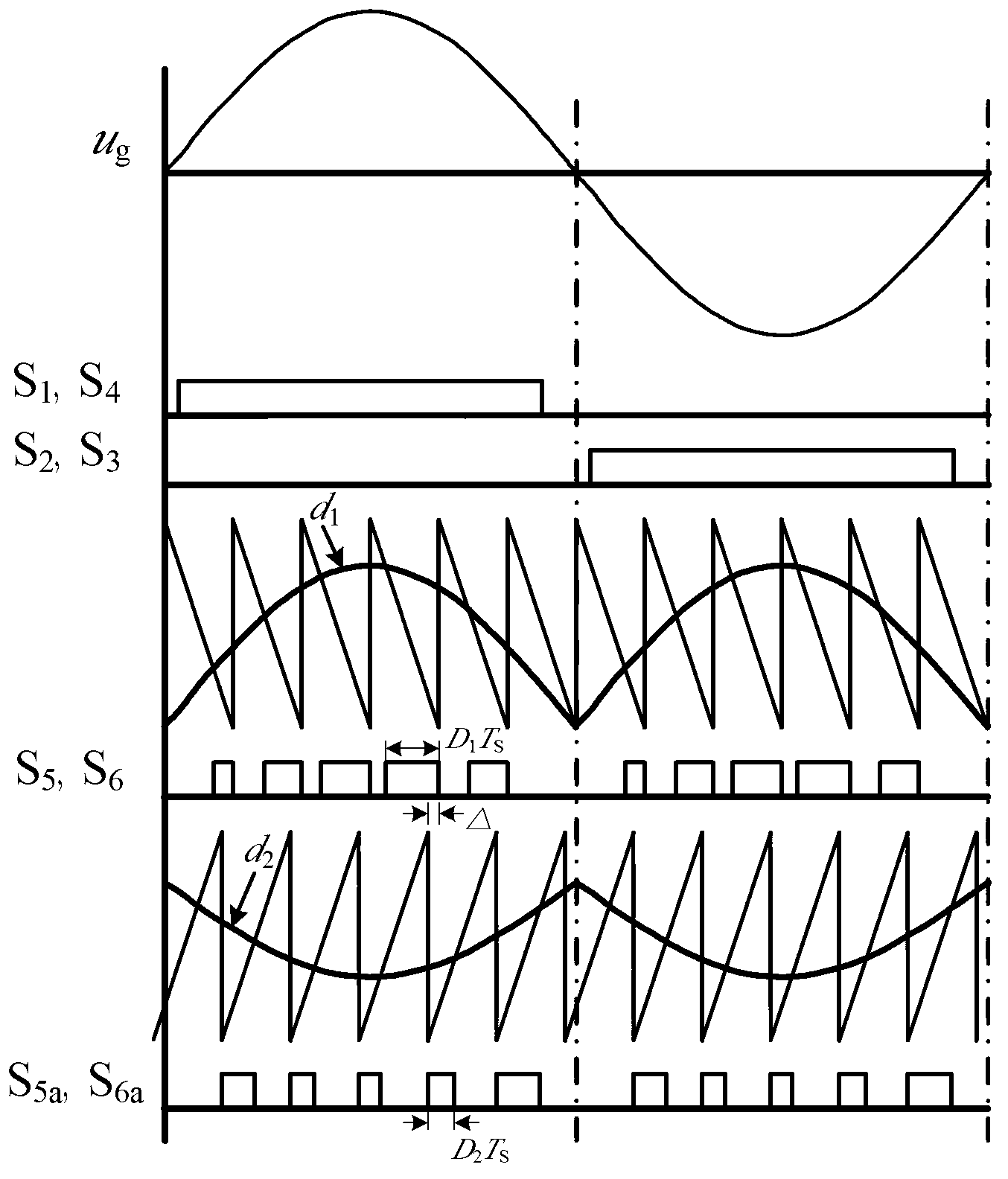

[0053] Figure 5(a)-(b) is the waveform diagram of grid voltage, grid current, differential mode and common mode voltage in a grid cycle of the present invention. It can be seen that the differential mode voltage is generated by unipolar SPWM, and the common mode The voltage is a constant value, consistent with the theoretical analysis.

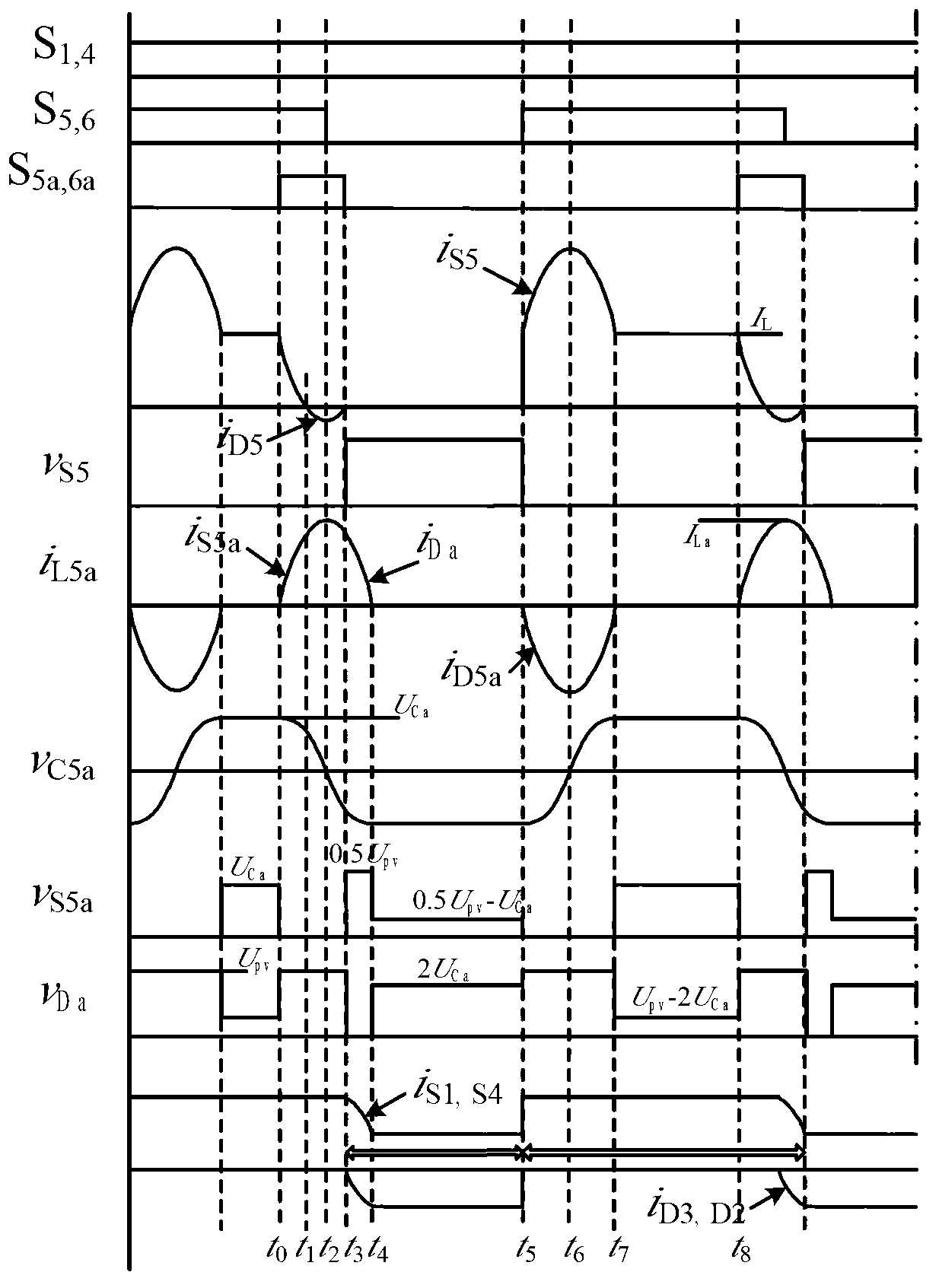

[0054] Figure 6 It is the working wave diagram of the resonant network in the present invention, the resonant network can work in resonance reliably, and the zero-current shutdown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com