Rotor position detection method of brushless direct current motor without sensor

A brushless DC motor and rotor position detection technology, applied in the direction of electronic commutator, etc., can solve the problems of low withstand voltage, no speed of motor, motor vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific examples.

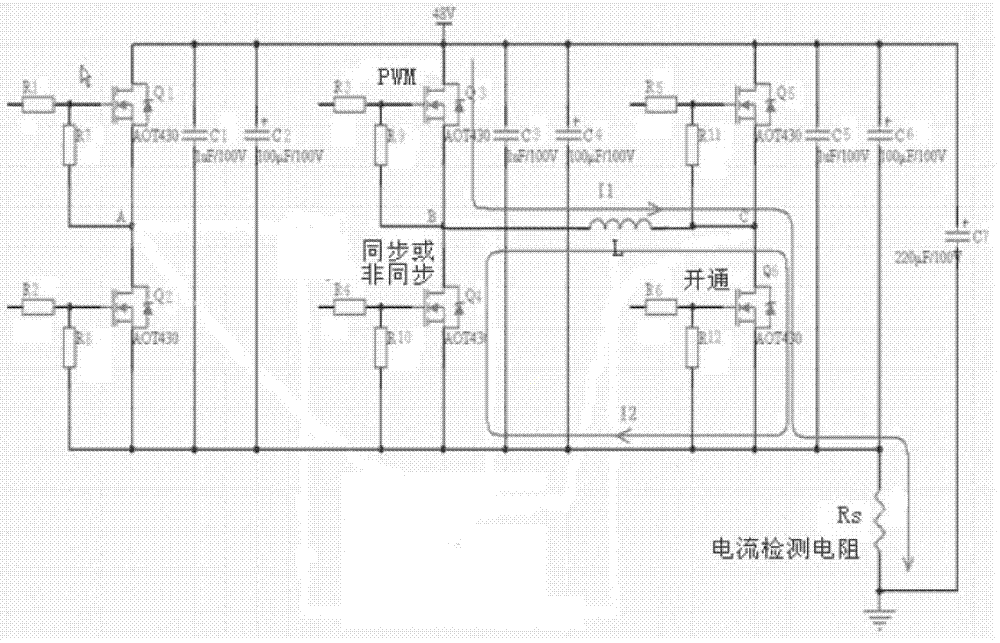

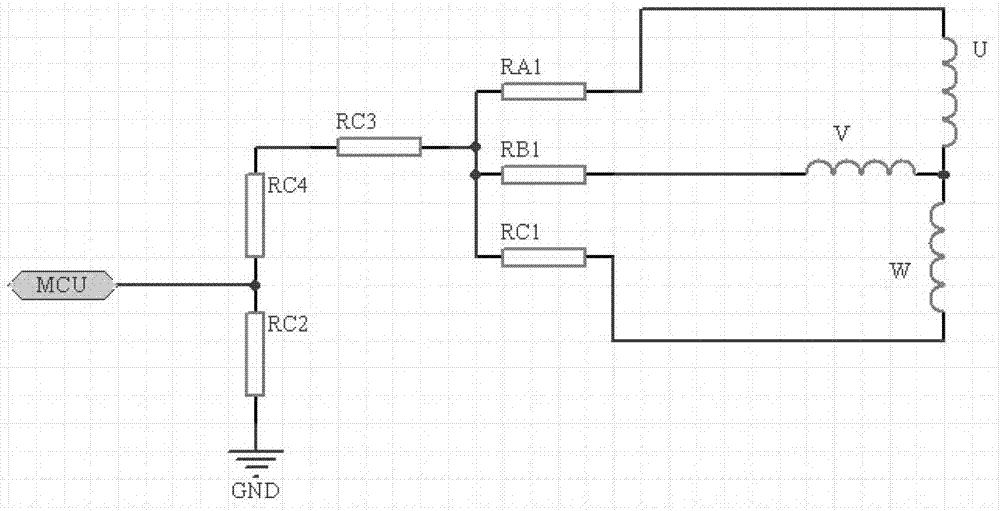

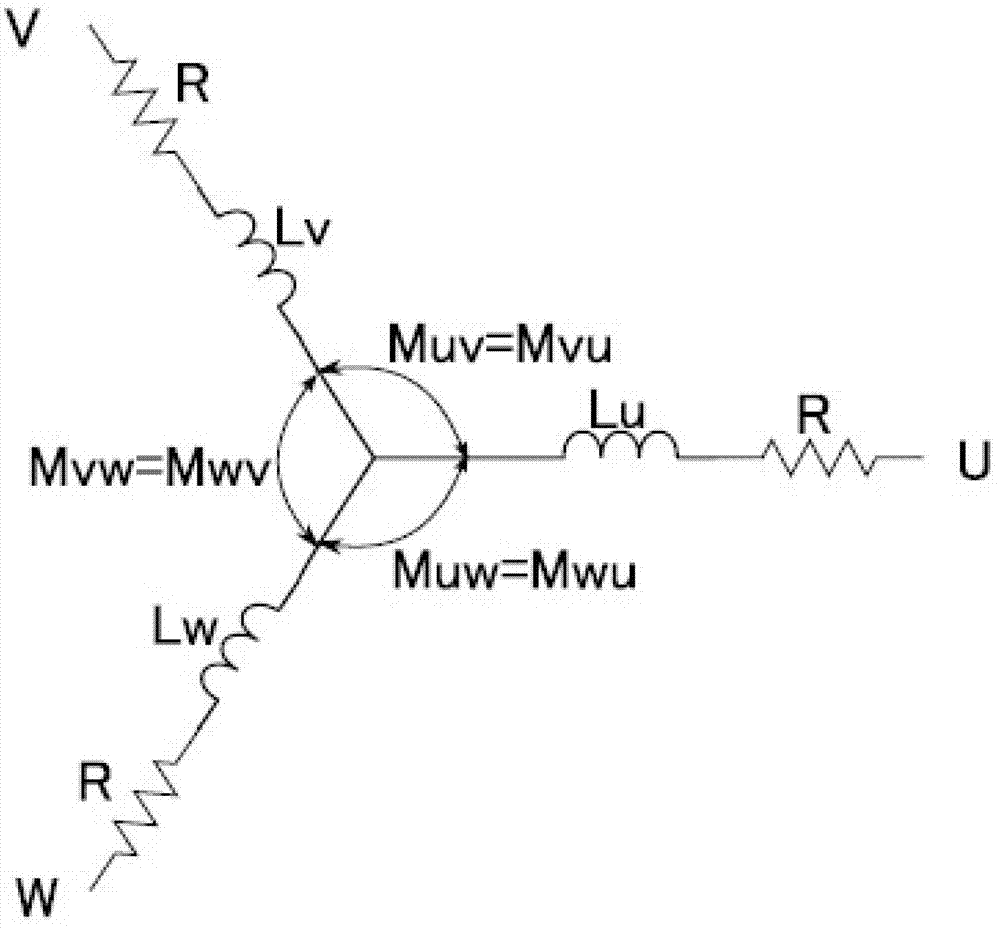

[0018] A method for detecting the rotor position of a sensorless DC brushless motor, the detection method includes a detection method for the starting position of the rotor and a detection method for the rotor position after the motor rotates, wherein the detection method for the starting position of the rotor adopts the motor coil magnetic flux with the permanent magnet The current relative position of the coil magnetic field and the permanent magnetic field is judged by the law of the magnetic field change, specifically: the three-phase circuit v, u, w of the motor are respectively connected to the symmetrical voltage Uvu, Uuv with the same pulse width and the same voltage value in advance. , Uvw, Uwv, Uuw, Uwu, the voltage is not enough to deflect the rotor of the motor, the voltage or current of the three-phase brushless DC motor coil is sampled, and the rotor coil and the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com