System and method for controlling and selecting granules on basis of structural sound field

A structural sound field and particle technology, which is applied in individual particle analysis, particle and sedimentation analysis, particle size analysis, etc., can solve the problems of inability to process micro-nano particles in batches, and achieve the effects of not being easily disturbed by external factors, high reliability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

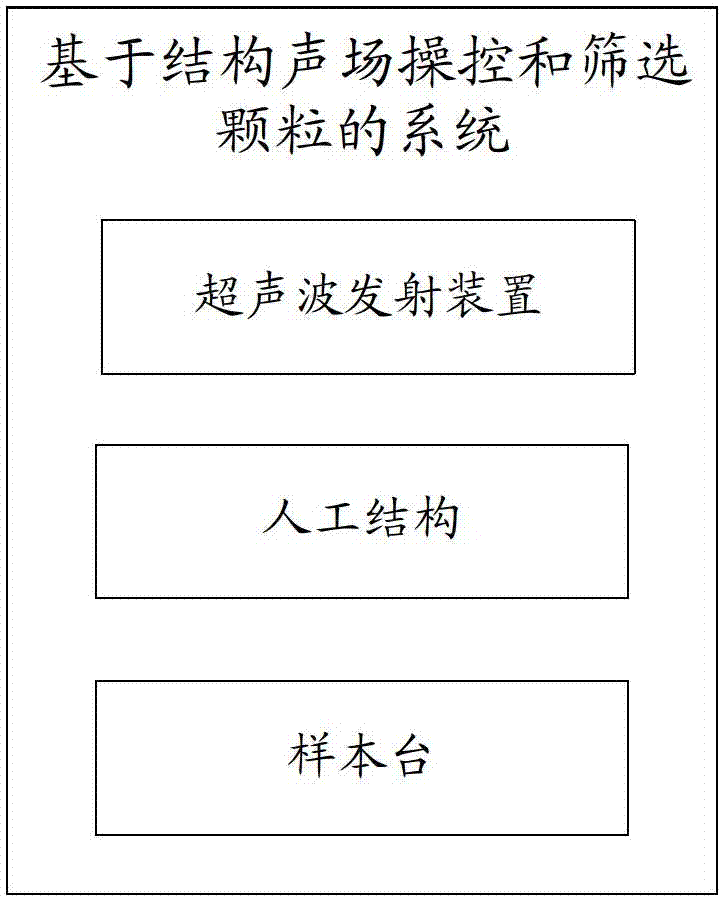

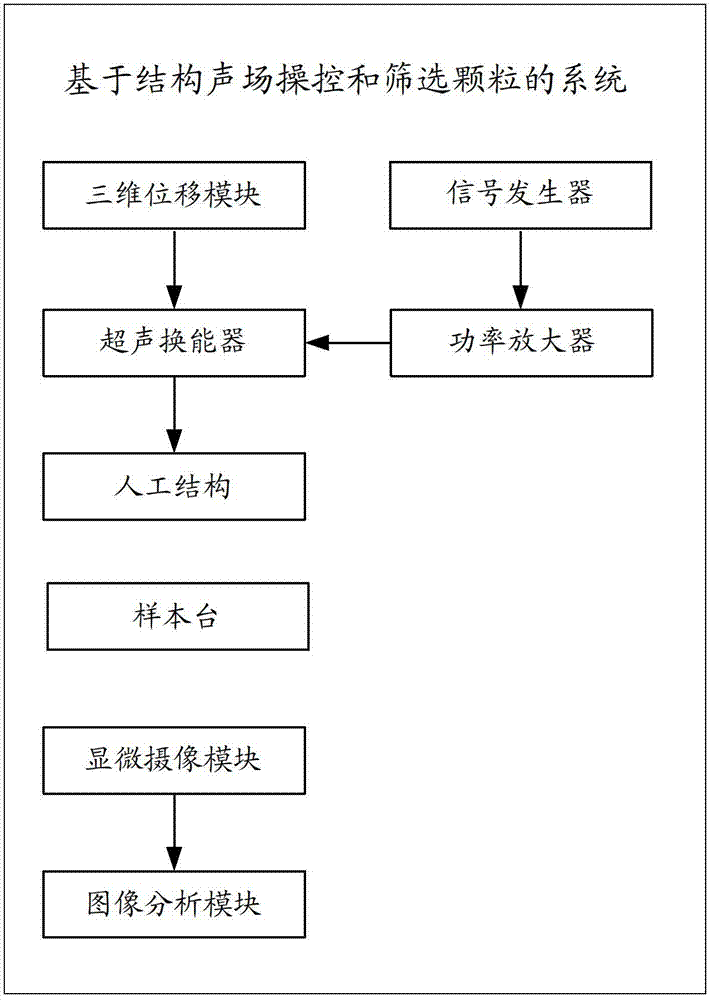

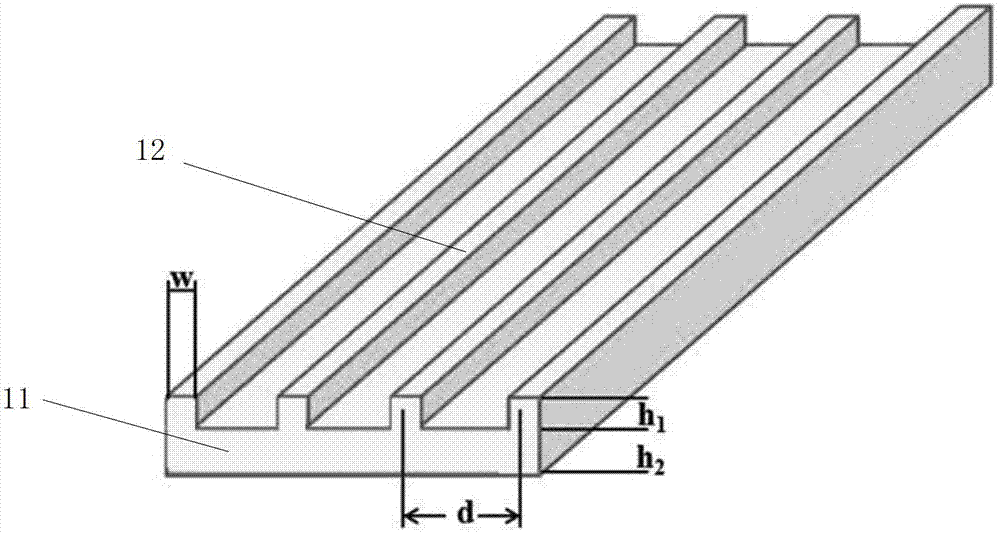

[0036] Such as Figure 1 to Figure 3 As shown, one embodiment of the system for manipulating and screening particles based on the structural acoustic field of the present application includes a sample table, an ultrasonic emitting device and an artificial structure. The sample table is used to hold particles to be screened, and the ultrasonic emitting device is used to emit ultrasonic waves. , the artificial structure is a periodic structure, which is used to modulate the sound field to generate stronger acoustic radiation force, and to screen the particles to be screened.

[0037] In one embodiment, the sample stage is a sound-transmitting phantom made of gel, and its height can be set as required. In this specific embodiment, the height of the sample stage is 4 cm.

[0038] In one embodiment, the ultrasonic transmitting device includes a signal generator, a power amplifier and an ultrasonic transducer, the signal generator is used to generate a transmitting signal, and the ...

Embodiment approach

[0045] Such as Figure 4 As shown, the method for manipulating and screening particles based on the structure acoustic field of the present application, an embodiment thereof, comprises the following steps:

[0046] Step 402: Place the particles to be screened on the sample table, and set the artificial structure above the sample table; in this embodiment, the particles to be screened can be selected from tiny glass balls, specifically pickling beads produced by Sigma-Aldrich. The glass microspheres G4649-100G, G1145-100G and G8772-100G. The diameters of these three glass microspheres are <106 μm, 150-212 μm and 425-600 μm, respectively.

[0047] Step 404: the ultrasonic emitting device emits ultrasonic waves;

[0048] Step 406: The artificial structure regulates the sound field;

[0049] Step 408: The artificial structure screens the particles to be screened based on the acoustic radiation force generated by the modulation. The artificial structure can adsorb the screened...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com