Device and method for stripping test of electro-fusion joint

A technology for peeling test and electrofusion joint, which is applied in the field of test equipment and electrofusion joint peeling test, to prevent bending, avoid toughness damage, and achieve effective peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

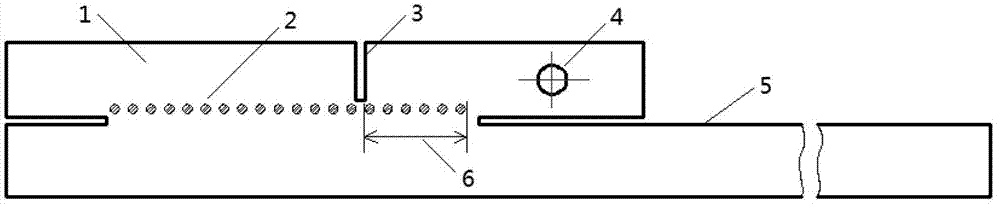

[0040] Sample to be tested: the sample to be tested is made according to the requirements of GB / T 19808-2005, and a narrow groove 3 deep to the upper surface of the heating resistance wire 2 is processed on the surface of the sample electrofusion sleeve 1, the groove 3 is located between the sixth and seventh resistance wires. Set up a traction hole at the extended end of the sleeve of the sample. The center of the traction hole is located on the upper and lower midlines of the sleeve, and the distance between the first resistance wire and the root of the sleeve is equal. Such as figure 1 .

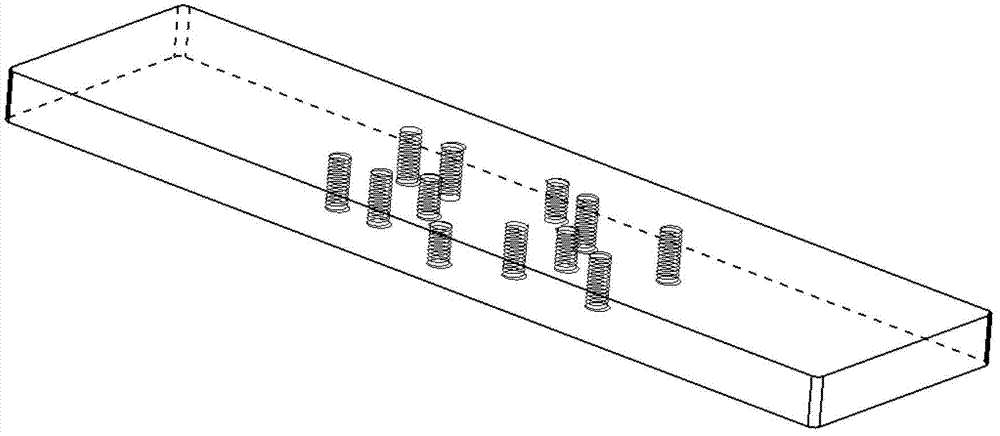

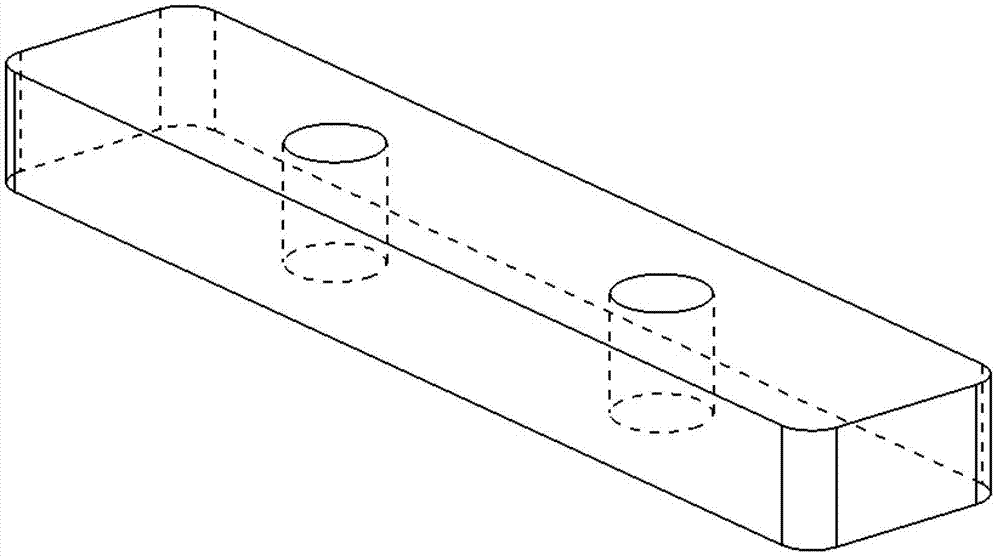

[0041]The bearing platform 7 of the peeling test device is as figure 2 As shown, the carrying platform 7 has 8 threaded through holes, the lower surface has 4 threaded blind holes around the center of the platform, and the central area of the upper surface is processed with staggered vertical and horizontal lines. End platen 8 such as image 3 As shown, the end pressing plate 8 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com