A device and method for absorbing and concentrating waste gas containing carbon dioxide

A carbon dioxide and exhaust gas technology, applied in chemical instruments and methods, through absorption, separation methods, etc., can solve the problems of secondary pollution of absorbents, large amounts of heat energy, and increased cost of flue exhaust gas treatment, so as to achieve cost saving and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

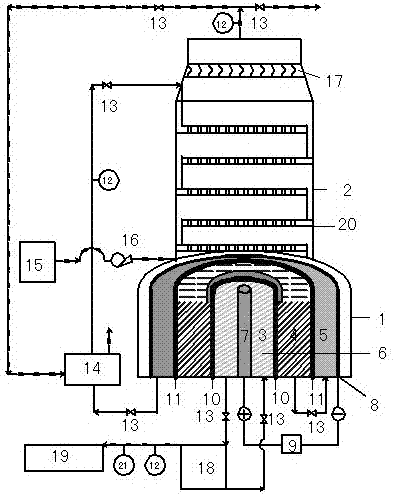

[0017] use as figure 1 The device for absorbing and recovering waste gas containing carbon dioxide is shown to treat the carbon dioxide gas produced in the coal-to-natural gas process. The concentration of carbon dioxide in the waste gas is about 18g / m 3 , gas flow 35m 3 / h, the removal rate of carbon dioxide in the exhaust gas is about 96.2%. After the alkaline absorption liquid absorbs carbon dioxide, the pH drops below 10.0. From about 10.0 to above 12.8, the anolyte pH is below 1.72.

Embodiment 2

[0019] use as figure 1 The device for absorbing and recovering waste gas containing carbon dioxide is shown to treat carbon dioxide gas produced during coke oven combustion. The operation steps and principles are the same as in Example 1, and the concentration of carbon dioxide in the waste gas is about 24g / m 3 , gas flow 20m 3 / h, the removal rate of carbon dioxide in the waste gas is about 95.0%, and the pH of the alkaline absorption liquid drops below 10.0 after absorbing carbon dioxide. From about 10.0 to above 13.1, the anolyte pH is below 1.80.

Embodiment 3

[0021] use as figure 1 The device for absorbing and recovering waste gas containing carbon dioxide is shown to treat carbon dioxide gas produced during coke oven combustion. The operation steps and principles are the same as in Example 1, and the concentration of carbon dioxide in the waste gas is about 45g / m 3 , gas flow 25m 3 / h, the removal rate of carbon dioxide in the exhaust gas is about 95.3%, the pH of the alkaline absorption liquid after absorbing carbon dioxide is 9.80~10.10, after entering the EDI carbon dioxide recovery unit, after the regeneration of the absorbent and the extraction of carbonic acid, the absorption liquid is changed from the original about The weak alkaline becomes above 13.2, and the pH of the anolyte is lower than 1.68.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com