Ultrahigh molecular-weight polyethylene composite tubing and production method thereof

A polyethylene composite pipe, ultra-high molecular weight technology, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problems of melt fracture, poor cutting resistance, poor creep resistance, etc. The effect of comprehensive manufacturing cost, improving pipe strength and reducing hoop deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

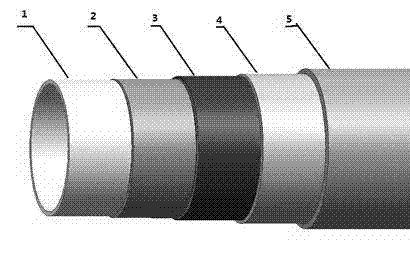

[0045] An ultra-high molecular weight polyethylene composite pipe has a 5-layer composite structure. The core pipe is an ultra-high molecular weight polyethylene pipe wound by stretched oriented sheets. The outer surface of the core pipe is coated with adhesive CILBOND 24, natural rubber, rubber Wrapped with a helically wound fiberglass tape 110 mm wide, the outer layer is an HDPE pipe layer.

[0046] The production method of the described high-strength ultra-high molecular weight polyethylene composite pipe comprises the following steps:

[0047] ①Extrude the ultra-high molecular weight polyethylene material with a molecular weight of 3.5 million to form a sheet, and then pass through the online straight section of the sheet and cut it into sheets of a certain width with a gang saw along the extrusion direction. The sheet is drawn at 145°C for 3.5 High-strength sheet is formed by stretching and drawing orientation;

[0048] ② Wrap the stretched and oriented ultra-high molecu...

Embodiment 2

[0060] An ultra-high molecular weight polyethylene composite pipe has a 5-layer composite structure. The core pipe is an ultra-high molecular weight polyethylene pipe wound by stretched oriented sheets. The outer surface of the core pipe is coated with polyethylene adhesive and styrene-butadiene rubber. The rubber is wrapped with a helically wound carbon fiber strip 110mm wide, with an outer layer of HDPE tubing.

[0061] The production method of the described high-strength ultra-high molecular weight polyethylene composite pipe comprises the following steps:

[0062] ①Extrude the ultra-high molecular weight polyethylene material with a molecular weight of 3.5 million to form a sheet, and then pass through the online straight section of the sheet and cut it into sheets of a certain width with a gang saw along the extrusion direction. The sheet is drawn at 145°C for 3.5 High-strength sheet is formed by stretching and drawing orientation;

[0063] ② The stretched and oriented u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com