High-resolution tomography optical microscopic imaging device for tissue samples

A tissue sample, high-resolution technology, applied in sampling devices, measuring devices, material analysis through optical means, etc., can solve problems such as the influence of optical imaging results, interference background, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

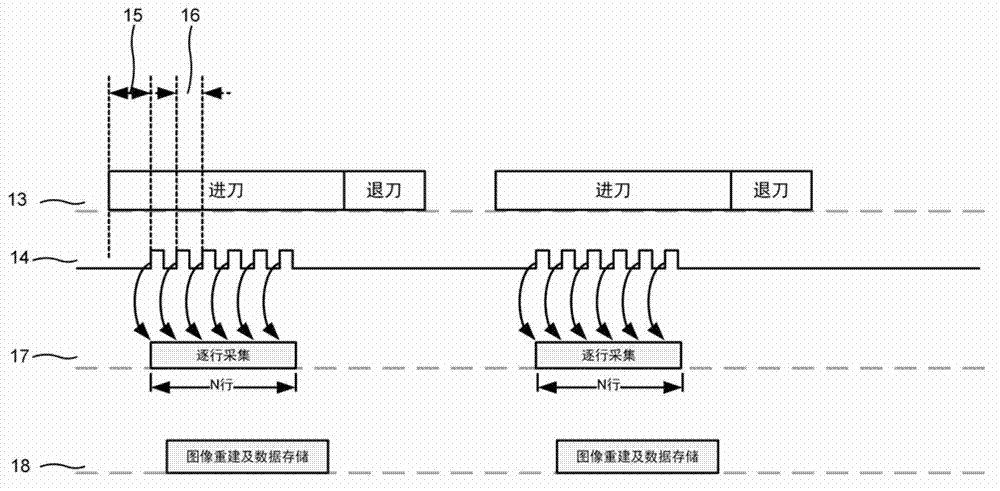

[0026] Such as Figure 4Shown is a mechanically ablated high-resolution tomographic optical microscopy system of a green fluorescent protein (GFP)-labeled tissue sample. The laser 19 outputs laser light with a wavelength of 488nm, passes through the cylindrical lens 20, and focuses the light beam at the focal length of the cylindrical lens 20 into a line light source. An excitation line is formed on the tissue slice 6 through the tube lens 21 and the objective lens 8 . The fluorescence signal of the sample excited by the excitation line is imaged on the photosensitive surface of the line array detector 24 through the objective lens 8 and the tube lens 21 to obtain one row of the fluorescence image of the slice 6 . As the slice moves, the slice 6 slides along the surface of the cutter 4 and is excited line by line by the 488nm excitation line. During the movement of the electric control platform along the direction 5, a trigger signal is generated for each moving distance of t...

Embodiment 2

[0029] The imaging system structure is as in embodiment 1, such as Figure 4 shown. Wherein the cutter 4 uses opaque tungsten carbide hard cutter or black diamond cutter. Because of the opacity of the tool material itself, there is no need to perform optical coating on the tool surface.

[0030] Other settings and steps of the imaging process are the same as those in Embodiment 1, so they are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com