Complementary Metal-Oxide-Semiconductor Transistor (CMOS) image sensor and production method thereof

An image sensor and area technology, applied in the field of CMOS image sensor and its preparation, can solve the problems of limiting the detection limit and dynamic range of image sensors, and achieve the effects of improving efficiency, reducing image delay, and increasing transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

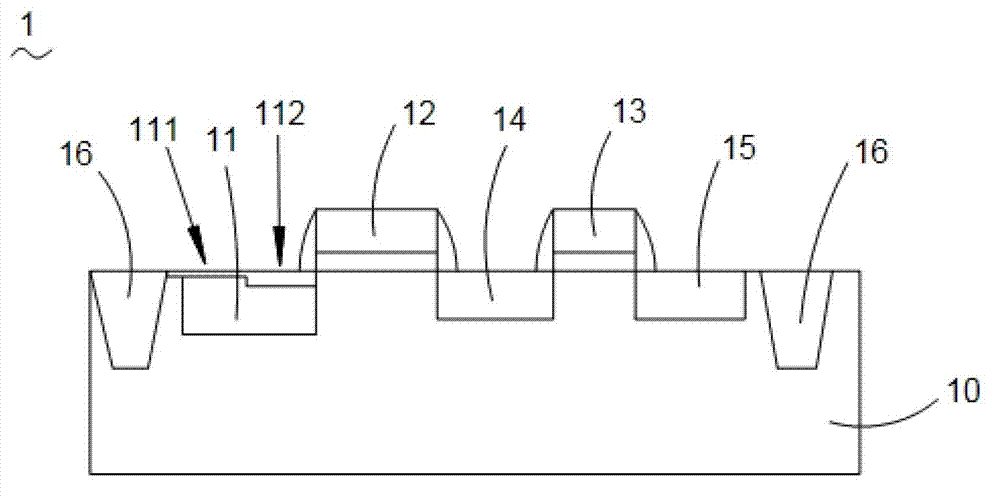

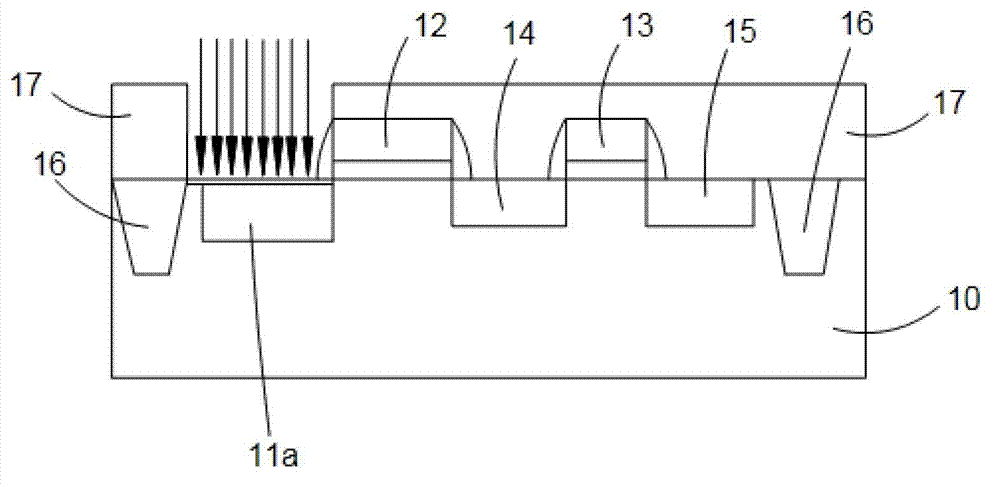

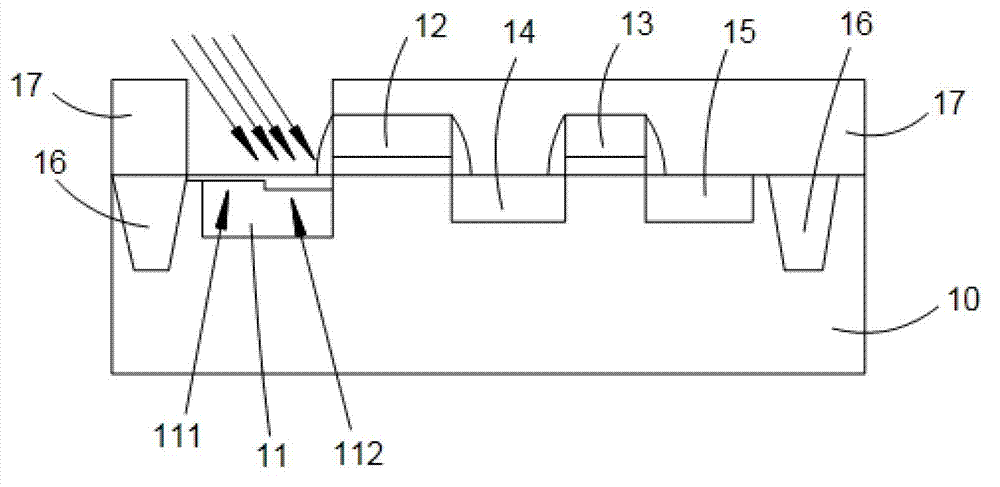

[0028] see figure 1 , figure 1 Shown is a schematic structural diagram of the CMOS image sensor of the present invention. The shown CMOS image sensor 1 includes a photodiode 11, a transfer transistor 12, a reset transistor 13, a first floating node 14, a second floating node 15 arranged in the semiconductor substrate 10, and an isolation structure for electrical isolation of devices 16, wherein the photodiode 11 has at least two first regions 111 and second regions 112 with different indium doping concentrations, and the indium doping concentration of the first region 111 at the far end of the transfer transistor 12 is lower than that at the Indium doping concentration of the second region 112 near the end of the transfer transistor 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com