Solar cell protective sheet and method for manufacturing same, solar cell backing sheet, and solar cell module

A technology of solar cells and protective plates, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of interlayer adhesion (poor connection, peeling, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

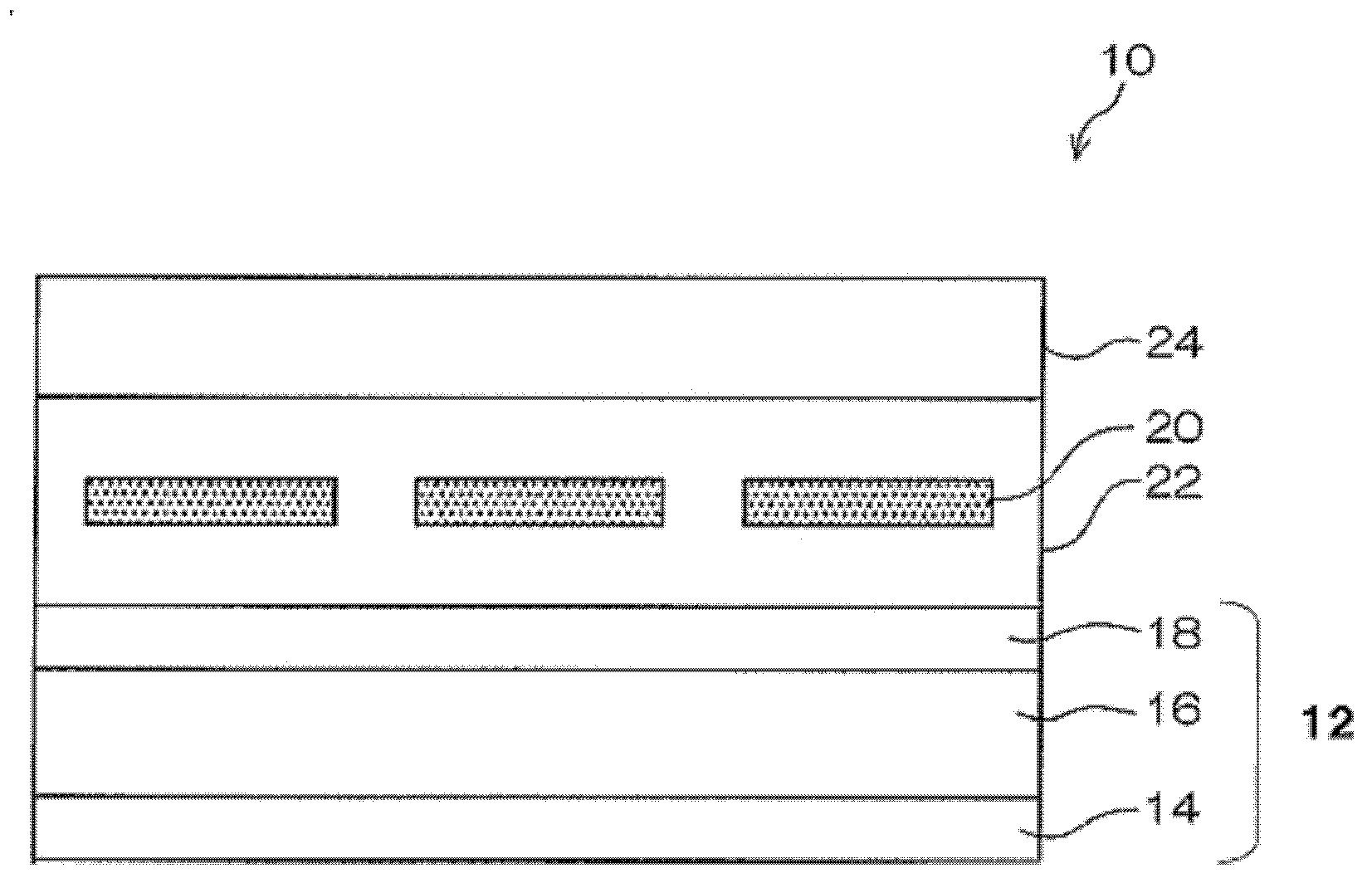

[0102] [Preparation method for solar cell protection sheet]

[0103] The production method of the solar cell protective sheet used in the present invention (hereinafter this may be referred to as the film production method of the present invention) includes by flame treatment with a silane compound kept introduced into the flame or by plasma treatment under atmospheric pressure The step of treating at least one surface of a polyethylene terephthalate substrate, and the step of coating the treated surface of the substrate with a coating composition comprising a fluoropolymer.

[0104] The production method of the present invention is described below.

[0105] (Preparation of starting PET resin)

[0106] Preferably, in the film production method of the present invention, a polyester resin having an intrinsic viscosity IV of 0.74 to 0.91 dL / g is used for melt film formation.

[0107] The starting PET resin whose IV falls within this range may be obtained by synthesis and polyme...

Embodiment 1

[0273] (1) Formation of weather-resistant polyester film

[0274] (Preparation of polyethylene terephthalate resin PET1)

[0275] A polyester resin was prepared by polymerization using a Ti catalyst according to the method mentioned below.

[0276] A slurry of 100 kg of high-purity terephthalic acid (manufactured by Mitsui Chemical) and 45 kg of ethylene glycol (Nippon Shokubai) was successively fed into an esterification tank in which about 123 kg of bis(hydroxyethyl) terephthalate, and keep it at a temperature of 250°C and at 1.2 x 10 5 At a pressure of Pa, it took 4 hours; and after the addition, the esterification was continued for another 1 hour. Subsequently, 123 kg of the esterification product thus obtained was transferred to a polycondensation tank.

[0277] Next, ethylene glycol was added in an amount of 0.3% by mass relative to the polymer to be obtained into the polycondensation tank in which the esterification product had been placed. After stirring it for 5 h...

Embodiment 2 to 10

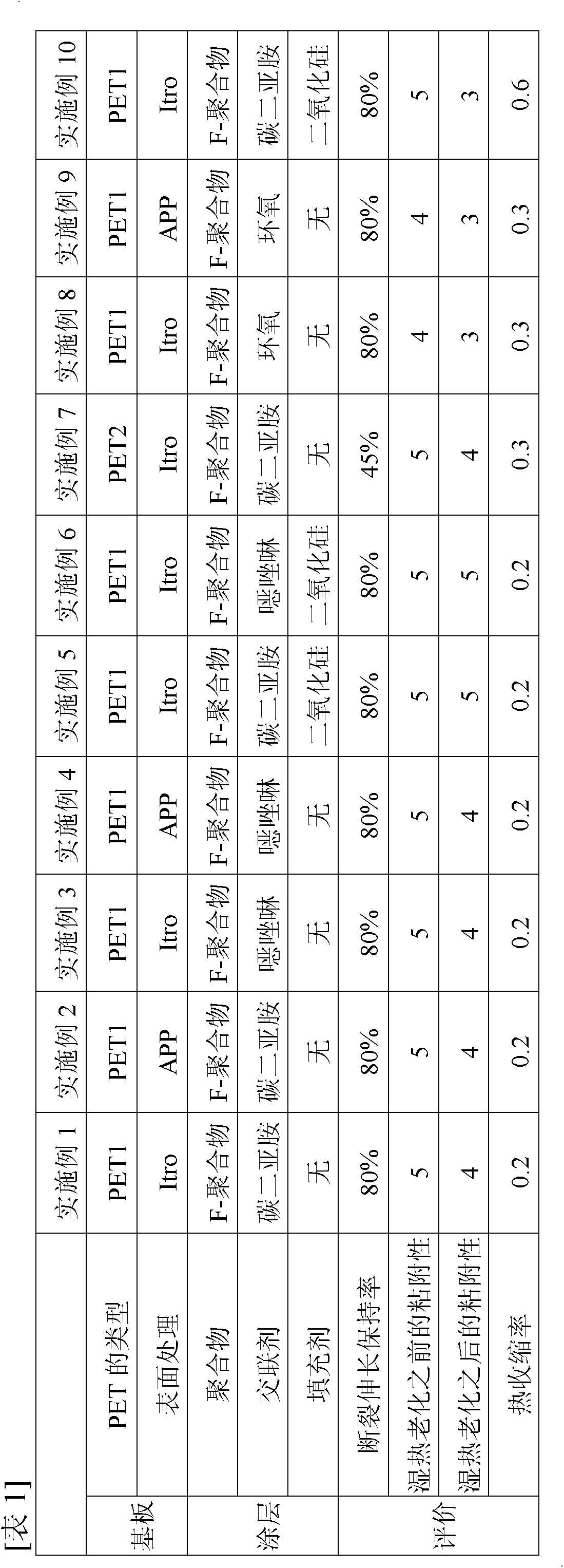

[0305] [Examples 2 to 10, Comparative Examples 1 to 10]

[0306] Examples 2 to 10 and The solar cell protection sheets of Comparative Examples 1 to 10. Details of some examples and comparative examples are described below.

[0307] In Example 2, one surface of a polyethylene terephthalate substrate was subjected to atmospheric plasma treatment under the conditions mentioned below.

[0308] When transported in an atmosphere of a plasma gas of air mixed with argon (gas pressure: 750 Torr), with plasma generated by discharge in a high-frequency discharger having a power supply frequency of 5 kHz at 250 W·min / m 2 The output discharge intensity irradiates the surface of PET-1 for 15 seconds.

[0309] In Example 3, using An oxazoline compound (Epocross WS-700, manufactured by Nippon Shokubai, solid content 25%) was used as a crosslinking agent instead of the carbodiimide compound.

[0310] In Example 5, 30 parts by mass of silica (manufactured by Nissan Chemical Industry) was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com