Inverter integrated motor-driven compressor

A technology of electric compressors and inverters, which is applied in the direction of machines/engines, liquid variable capacity machines, electrical components, etc., can solve the problems of increased common state coils, large size and high cost, etc., and achieves the reduction of electromagnetic radiation Effects of noise reduction, cost reduction, and miniaturization and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

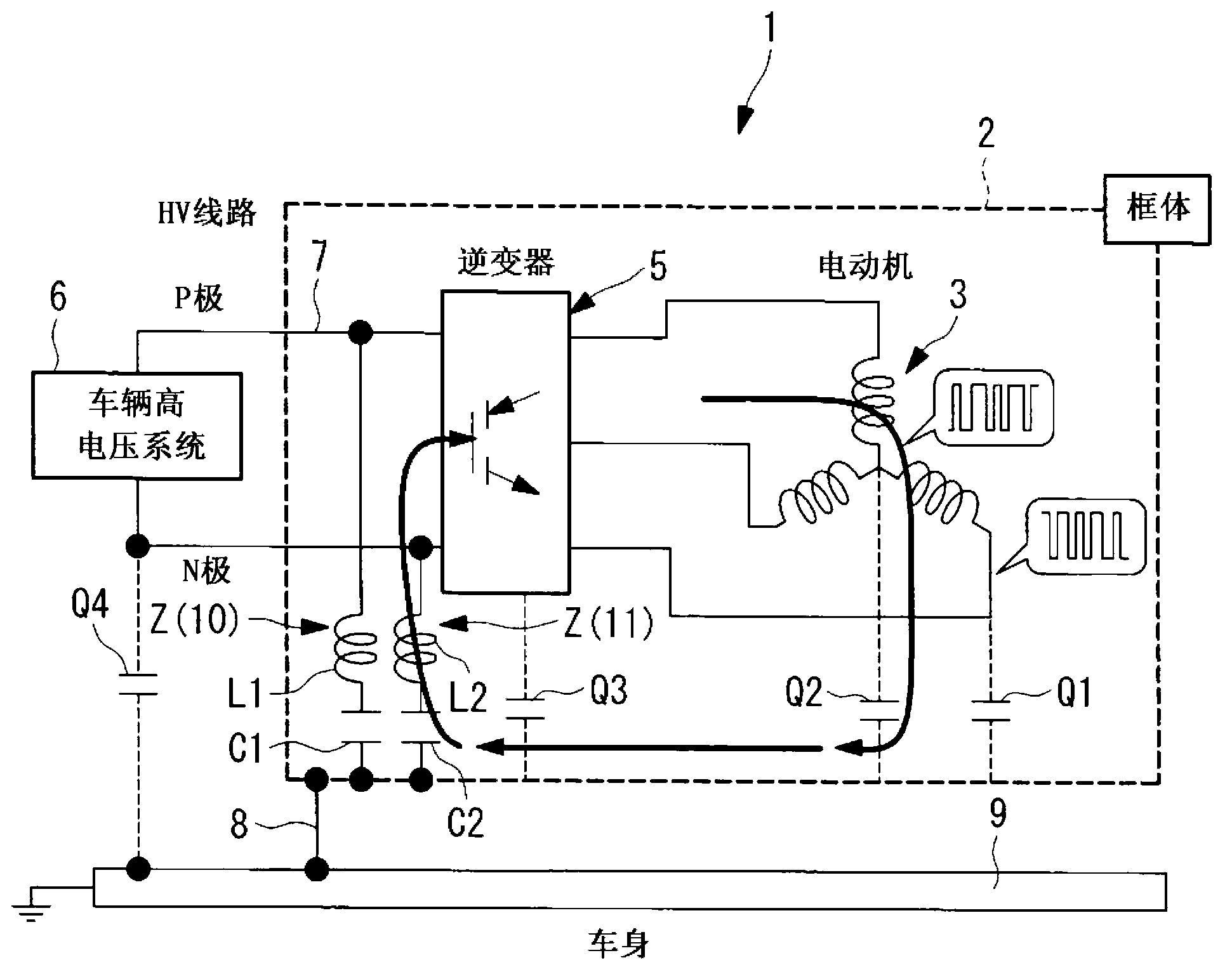

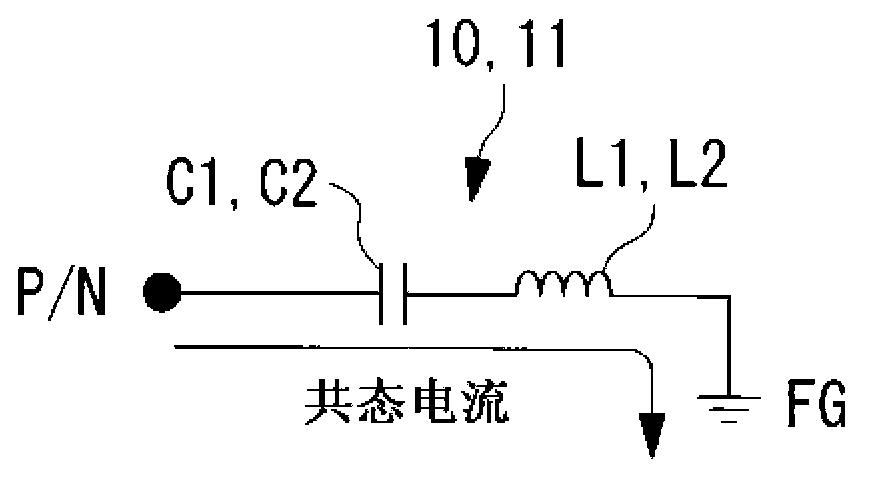

[0033] Below, use Figure 1 to Figure 6 , the first embodiment of the present invention will be described.

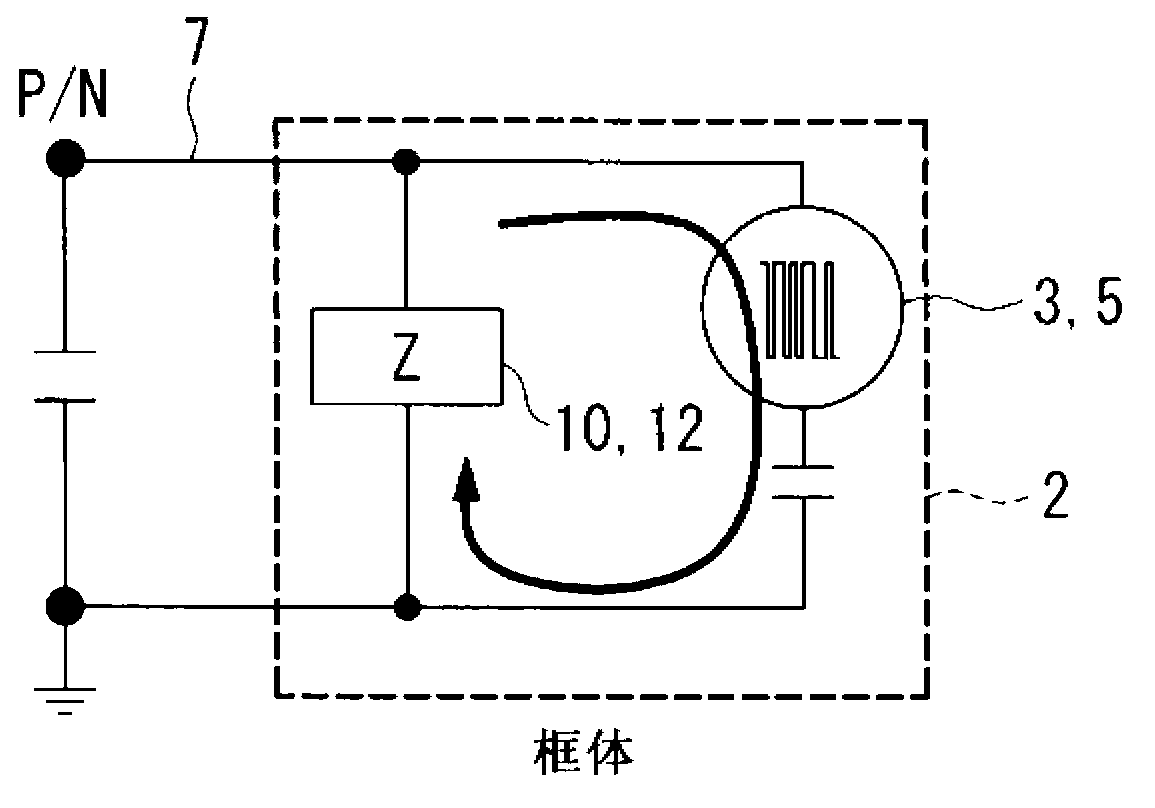

[0034] figure 1A schematic diagram showing a motor drive system circuit of an inverter-integrated electric compressor according to a first embodiment of the present invention, figure 2 Represents its sketch. and, Figure 6 It is a schematic diagram showing a schematic configuration of an inverter-integrated electric compressor.

[0035] The inverter-integrated electric compressor 1 includes a casing (frame) 2 made of a conductor made of aluminum die-casting, and a compression mechanism (not shown) and a motor for driving the compression mechanism are built in the casing 2 3.

[0036] In the outer circumference of the casing 2, an inverter housing part 4 is integrally formed (refer to Figure 6 ), and the inverter 5 is accommodated in the inverter accommodating portion 4 , thereby constituting the inverter-integrated electric compressor 1 in which the inverter 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com