Multi-functional photocatalyst diatom purification particles and preparation method thereof

A particle purification and multi-functional technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problem of inability to remove harmful substances such as formaldehyde, and achieve the effect of ensuring pure naturalness, mature technology, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1 The photocatalyst multifunctional diatom purified granule of the present embodiment comprises the following components by weight: 50 parts of diatomite, 5 parts of attapulgite, 10 parts of zeolite powder, 5 parts of sepiolite, negative ion 5 parts of powder, 3 parts of far-infrared ceramic powder, 20 parts of kaolin; 5 parts of nano photocatalyst.

Embodiment 2

[0013] Embodiment 2 The photocatalyst multifunctional diatom purified granule of the present embodiment comprises the following components by weight: 70 parts of diatomite, 15 parts of attapulgite, 20 parts of zeolite powder, 10 parts of sepiolite, negative ion 8 parts of powder, 5 parts of far-infrared ceramic powder, 30 parts of kaolin; 15 parts of nano photocatalyst.

Embodiment 3

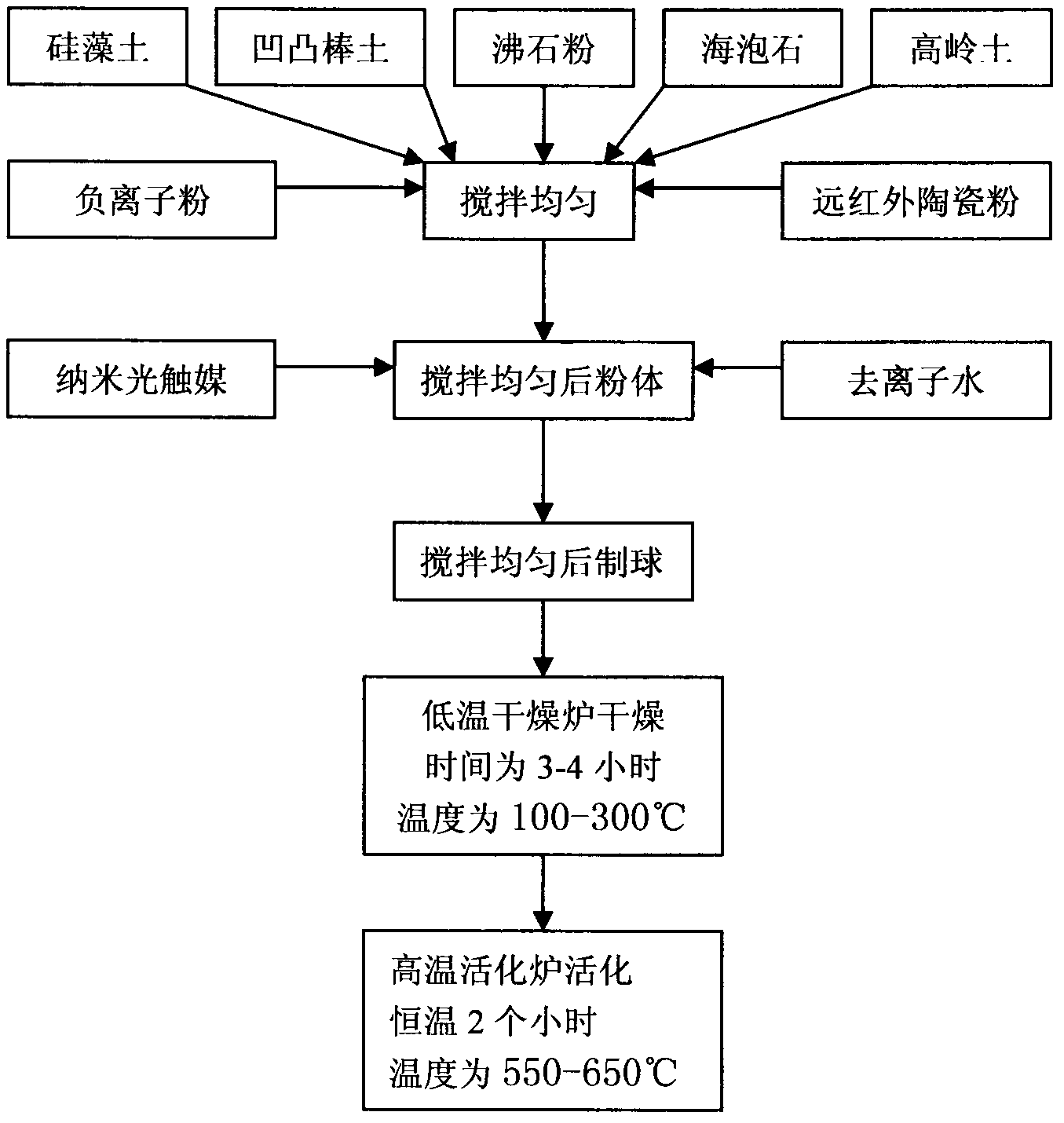

[0014] Embodiment 3 The photocatalyst multifunctional diatom purification particle preparation method of the present embodiment, technological process is as follows figure 1 As shown, the specific steps are as follows:

[0015] 1. Stir and mix 50 parts of diatomite, 5 parts of attapulgite, 15 parts of zeolite powder, 5 parts of sepiolite, 5 parts of negative ion powder, 3 parts of far-infrared ceramic powder, and 30 parts of kaolin; The fineness of stick clay, zeolite powder and sepiolite is 1250-3000 mesh, and the purity of effective substances is above 90%; the release amount of negative ion powder is 10,000-50,000;

[0016] 2. Add 10 parts of nano-photocatalyst and appropriate amount of deionized water to the mixed powder, stir evenly, and then granulate into balls;

[0017] 3. Put the pellets into a low-temperature drying furnace for primary drying for 3 hours at a drying temperature of 100°C; put the pellets into a high-temperature activation furnace for activation at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com