Coaxial water jet device used for laser micro machining of thin-walled tube

A thin-walled pipe and water jet technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as thermal damage, debris is difficult to remove, and the service life of the workpiece is low, so as to avoid thermal damage and scorching, Improve processing quality and reduce the effect of heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

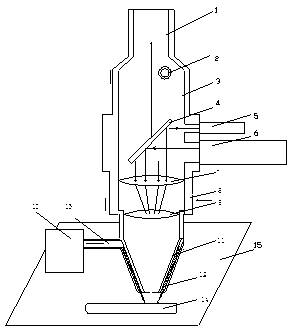

[0025] A coaxial water jet device for laser micromachining of thin-walled tubing, such as figure 1 As shown, it is hollow cylindrical, with a photoelectric sensor mounting seat 3 on the upper end. The photoelectric sensor 1 and the photoelectric sensor focusing knob 2 are arranged on the photoelectric sensor mounting seat 3, and below the photoelectric sensor mounting seat 3. The coaxial water jet device is equipped with There are 45 0 Mirror 4, with 45 0 On the side wall of the cylinder corresponding to the reflecting mirror 4, an illumination source 5 is provided, and a laser generator 6, 45 is provided below the illumination source 5 0 A focusing mirror 7 is provided below the reflecting mirror 4, and a focusing mirror focusing differential head 8 is provided on the corresponding cylinder side wall of the focusing mirror 7. A protective mirror 9 is provided below the focusing mirror 7, and a double-layer mirror is provided below the protective mirror 9. The nozzle 11 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com