Method and device for improving reliability of automobile seal element

A sealing and reliability technology, applied in the field of auto parts, can solve the problems of deformation, shedding, and poor sealing of automobile sealing strips, and achieve the effects of improving friction and clamping force, increasing working life, and improving working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

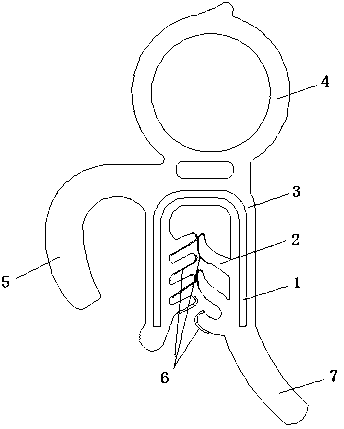

[0010] Embodiments of the present invention: a method for improving the reliability of automobile seals, increasing the clamping force and friction coefficient of the sponge colloid clamping teeth on both sides of the inner wall of the compact colloid of the seal strip, so as to reduce the influence of the tangential force on the automobile seal; The top of the dense colloid of the sealing strip is provided with a tubular sponge colloid to buffer the closing force and play the role of shock absorption and sound insulation.

[0011] The structure of the method of improving the reliability of automotive seals such as figure 1 As shown, the sealing strip compact colloid 3 is included, and the sponge colloid clamping teeth 2 are arranged on both sides of the inner wall of the sealing strip compact colloid 3, and an inverted U-shaped sealing strip steel belt 1 is arranged in the sealing strip compact colloid 3, and the sponge colloid The tooth end of the colloid clamping tooth 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com