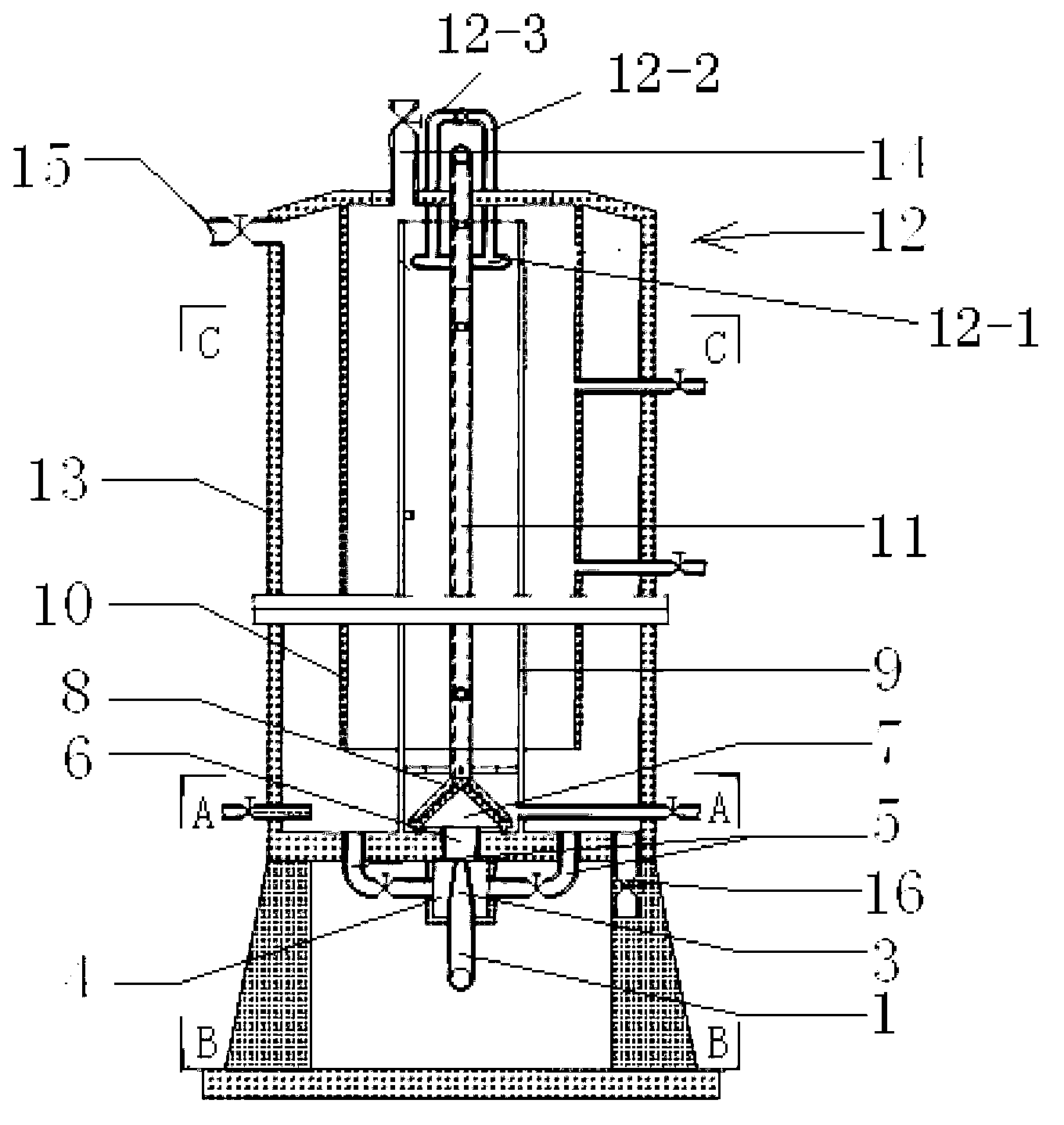

Bidirectional flow internal circulation type PS advanced oxidation reactor and sewage treatment method

A sewage treatment method and sewage treatment technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of low volume utilization, difficult construction, and large hydraulic loss, so as to reduce the reduction of free radicals and increase the ferrous Utilization rate and the effect of saving dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

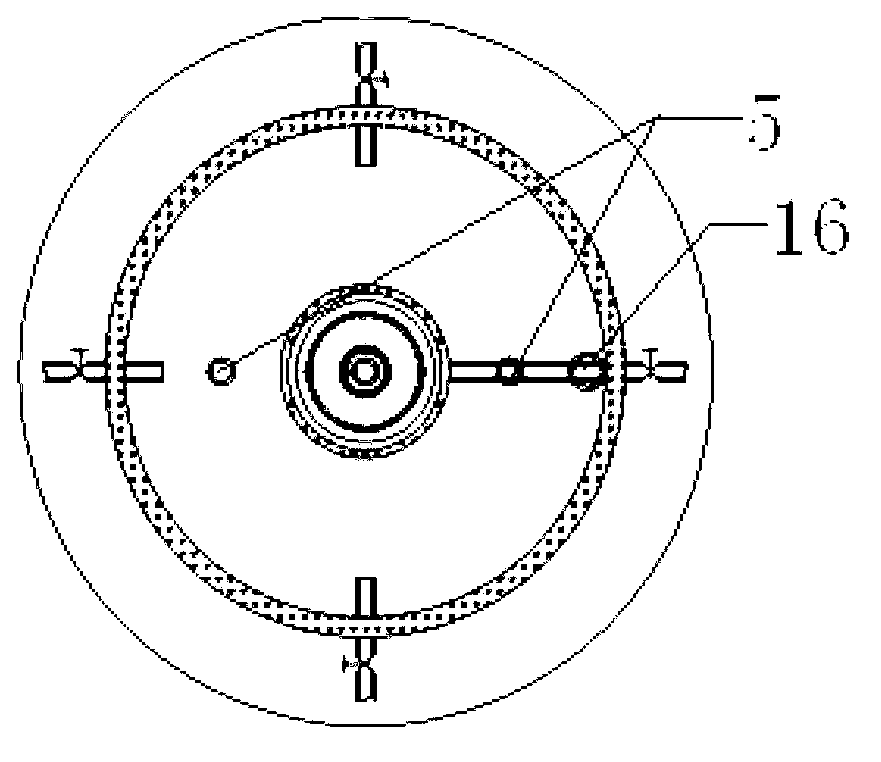

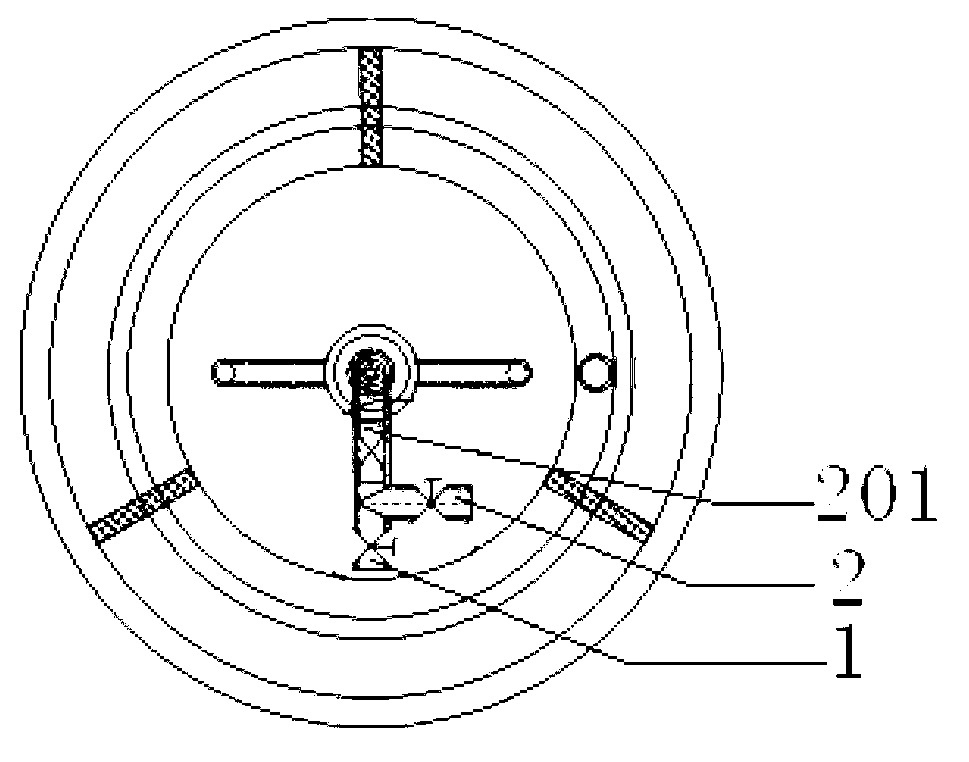

Method used

Image

Examples

Embodiment

[0039] A kind of sewage treatment method, mainly carries out according to the following steps:

[0040] 1. Configure the sewage treatment liquid in the dosing box respectively:

[0041] COD in PS solution and sewage CR The mass ratio is 6~12:1;

[0042] When the complexing agent is citric acid, the mass ratio of citric acid and ferrous sulfate solution used is 3.5~7:1 respectively;

[0043] When the complexing agent is oxalic acid, the mass ratio of oxalic acid and ferrous sulfate solution used is 1.6~3.2:1 respectively;

[0044] The mass ratio of PS solution to ferrous sulfate solution is 4.25~8.5:1;

[0045] Two, open the valves on the sewage inlet pipe, oxidant dosing pipe and catalyst dosing pipe, start the sewage water inlet pump, oxidant dosing pump and catalyst dosing pump, sewage and sewage treatment liquid are pumped into the reactor 13 respectively, adjust The flow rate of the pump makes the hydraulic retention time of the reactor 120min;

[0046] 3. After 70 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com