Wet desulphurization wastewater treatment device for limestone and gypsum

A wet desulfurization and wastewater treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problem of high operation and maintenance costs, equipment footprint The problem is that the effluent can only be discharged, so as to achieve the effect of low operation and maintenance cost and small floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

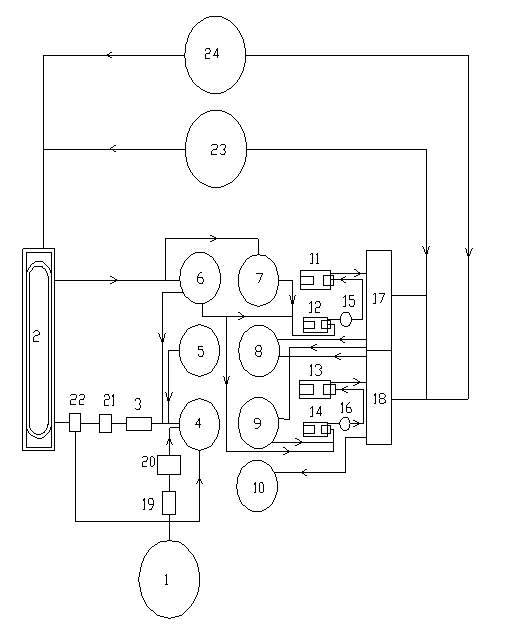

[0038] see figure 1 , the present invention relates to a limestone and gypsum wet desulfurization wastewater treatment device, which is mainly composed of a sedimentation system, an ultrafiltration system, a reverse osmosis system, a cleaning device 23 and a flushing device 24. The sedimentation system includes a wastewater sedimentation tank 1 and a pump 19 And filter 20, the ultrafiltration system includes tubular ultrafiltration membrane device 2, ultrafiltration circulation pump 3, pressure gauge, flowmeter and ultrafiltration circulation bucket 4, and described reverse osmosis system includes one-stage reverse osmosis into water bucket 7, two Level reverse osmosis water bucket 9, first level reverse osmosis feed pump 11, first level reverse osmosis water pump 12, first level reverse osmosis security filter 15, second level reverse osmosis feed pump 13, second level reverse osmosis water pump 14, Secondary reverse osmosis security filter 16, dosing barrel, dosing pump, fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com