Synthesis method of tridecyl trimellitate

A technology for the synthesis of tridecyl tripentellitate, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of high production costs, cumbersome reactions, and harsh conditions, and achieve operational Convenience, mild reaction conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

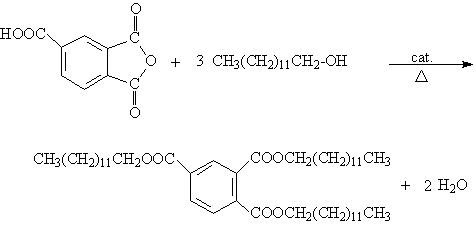

Method used

Image

Examples

Embodiment 1

[0013] Add 67 g of trimellitic anhydride, then 300 g of tridecyl alcohol into the three-necked flask, and finally add 0.2% catalyst tetrabutyl titanate whose mass is the total mass of trimellitic anhydride and tridecyl alcohol. Then connect the water separator, start stirring, pass nitrogen protection, and at the same time raise the temperature to 200-210°C and keep it warm. The water separator continuously removes the water generated by the reaction, and the esterification reaction ends when no water comes out. Then lower the temperature to 120°C, change the water separation reaction device into a vacuum distillation device, and dealcoholize under reduced pressure and vacuum until almost no tridecyl alcohol fraction is distilled out (tridecyl alcohol can be recycled). Then the whole system was cooled to 90°C, added a small amount of KOH aqueous solution to wash, and then transferred to a separatory funnel for extraction and layering. The lower water layer was removed, and the...

Embodiment 2

[0015] 100 g of trimellitic anhydride was added to the three-necked flask, then 450 g of tridecyl alcohol was added, and finally a catalyst p-toluenesulfonic acid whose mass was 1.0% of the total mass of trimellitic anhydride and tridecyl alcohol was added. Then connect the water separator, start stirring, pass nitrogen protection, and at the same time raise the temperature to 210-220°C and keep it warm. The water separator continuously removes the water generated by the reaction, and the esterification reaction ends when no water comes out. Then lower the temperature to 120°C, change the water separation reaction device into a vacuum distillation device, and dealcoholize under reduced pressure and vacuum until almost no tridecyl alcohol fraction is distilled out (tridecyl alcohol can be recycled). Then the whole system was cooled to 90°C, added a small amount of KOH aqueous solution to wash, and then transferred to a separatory funnel for extraction and layering. The lower wa...

Embodiment 3

[0017] Add 50 g of trimellitic anhydride in the three-necked flask, then add 225 g of tridecyl alcohol, and finally add catalyst sulfuric acid whose mass is 2% of the total mass of trimellitic anhydride and tridecyl alcohol. Then connect the water separator, start stirring, pass nitrogen protection, and at the same time raise the temperature to 200-210°C and keep it warm. The water separator continuously removes the water generated by the reaction, and the esterification reaction ends when no water comes out. Then lower the temperature to 120°C, change the water separation reaction device into a vacuum distillation device, and dealcoholize under reduced pressure and vacuum until almost no tridecyl alcohol fraction is distilled out (tridecyl alcohol can be recycled). Then the whole system was cooled to 90°C, added a small amount of KOH aqueous solution to wash, and then transferred to a separatory funnel for extraction and layering. The lower water layer was removed, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com