Thermal power generating unit loading control system and method based on continuously adjustable back pressure

A load control, thermal power unit technology, applied in mechanical equipment, steam engine installations, machines/engines, etc., can solve problems such as large delay of boiler, large delay furnace side, limitation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

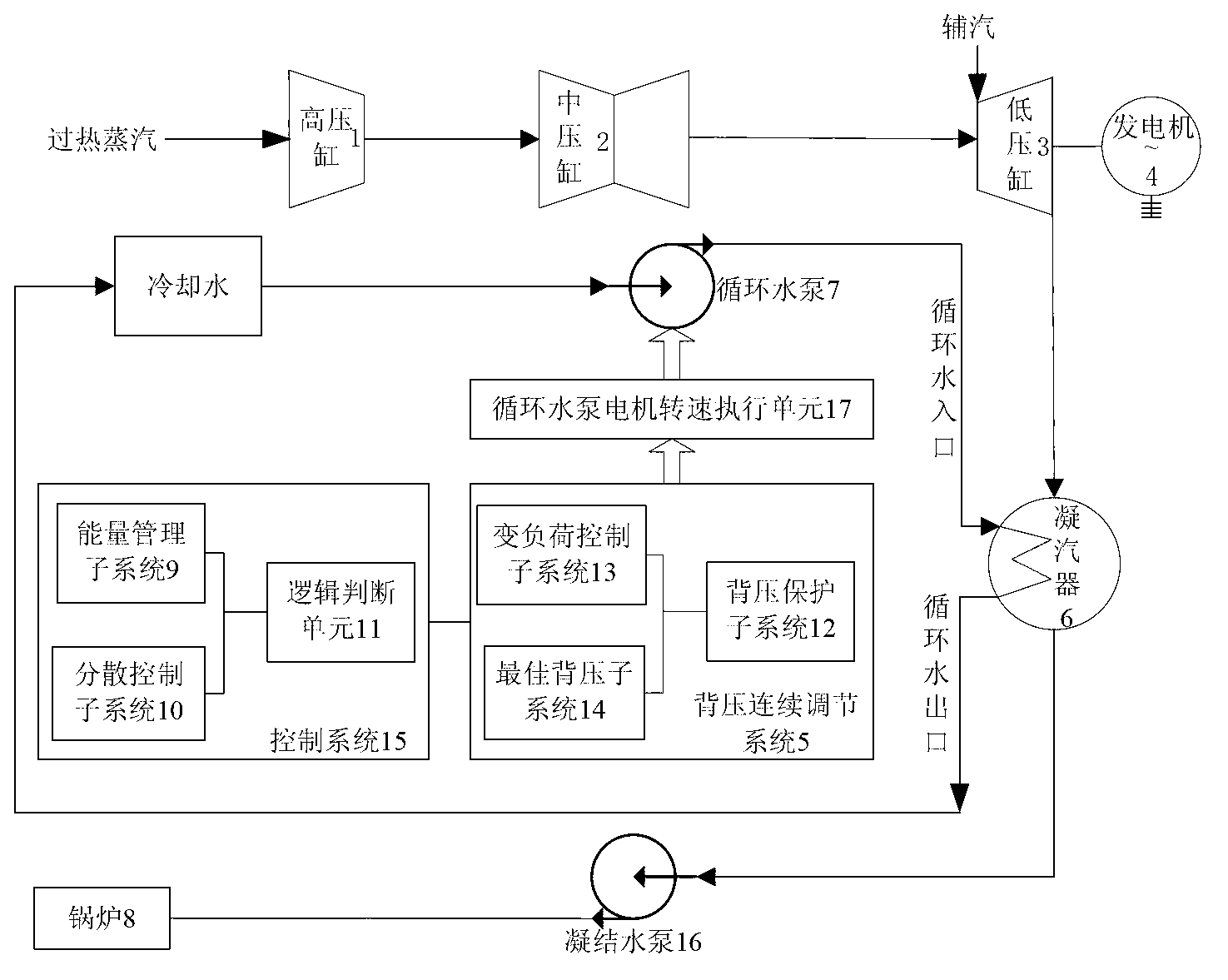

[0037] The back pressure continuous regulation system consists of variable load control subsystem 13, back pressure protection subsystem 12 and optimal back pressure subsystem 14, such as image 3 shown. Among them, the back pressure protection subsystem 12 needs to keep running at all times, and the variable load control subsystem 13 and the optimal back pressure subsystem 14 are operated by "choosing one of the two". The back pressure protection subsystem 12 and the optimal back pressure subsystem 14 operate in combination to realize the safe and economical operation of the unit; The back pressure protection subsystem 12 and the variable load control subsystem 13 operate in combination to increase the variable load rate of the unit as much as possible on the basis of ensuring the safe operation of the unit.

[0038] The whole implementation proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com