Fuel injector

A fuel injector and fuel injection technology, applied in the direction of fuel injection device, special fuel injection device, charging system, etc., can solve the problems of reducing control pressure, delayed response characteristics, etc., achieving freedom of recovery, reducing control volume, reducing The effect of manufacturing costs and coordination costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

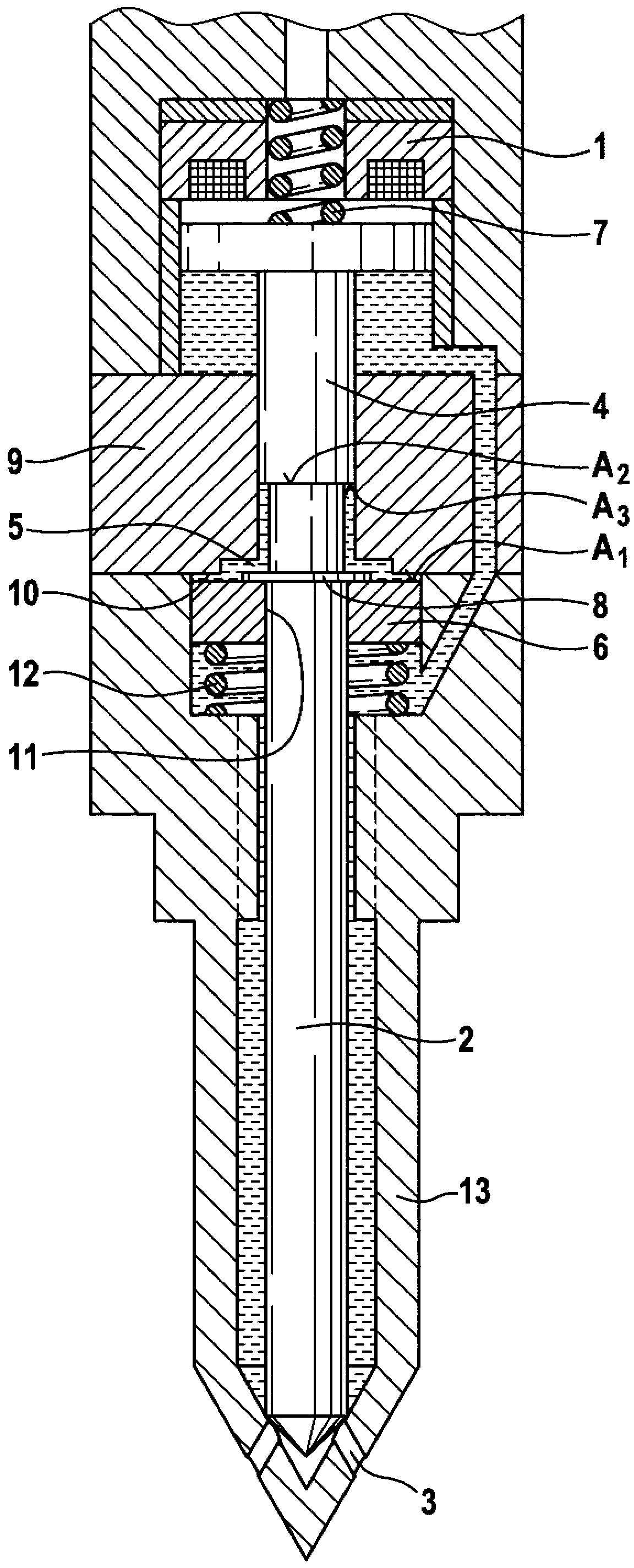

[0014] The illustrated fuel injector according to the invention has an electromagnetic actuator 1 for actuating an injection valve component 2 . The injection valve member 2 causes reciprocating opening and closing of at least the injection opening 3 in the nozzle body 13 . For actuating the injection valve member 2, the electromagnetic actuator 1 has a likewise reciprocating armature element 4 with a hydraulic working surface A for controlling the volume 5 in the axial direction 3 Boundary. When the electromagnetic actuator 1 is switched on, the armature element 4 moves in the direction of the actuator and in this way causes a pressure drop in the control volume 5 . Because the control volume 5 is also composed of the hydraulic working surface A constructed on the hydraulic converter 6 1 and the hydraulic face A formed on the injection valve component 2 2 The limit realizes the hydraulic coupling between the control volume 5 and the armature element 4 . This means that hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com