Amidation mesona chinensis benth glue and preparation method thereof

A technology for amidation of jelly and jelly grass glue is applied in the field of food processing technology to achieve the effects of low usage, improved gel performance and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

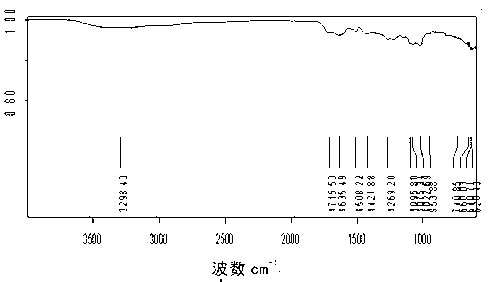

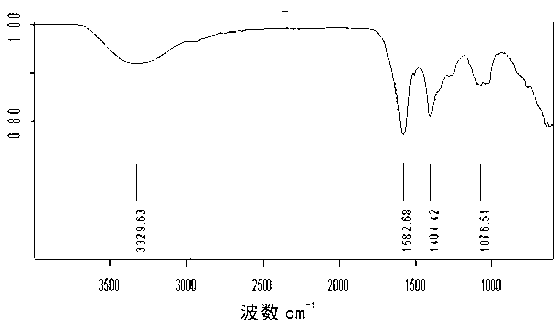

Image

Examples

Embodiment 1

[0038] A preparation method for amidated jelly gum, specifically comprising the steps of:

[0039] (1) Preparation of solution

[0040] The preparation of jelly jelly gum aqueous solution:

[0041] The jelly gum that passed through the 60-mesh sieve is calculated by weight ratio, that is, the ratio of jelly jelly gum to distilled water is 14:100, and the jelly jelly gum is fully dissolved in distilled water and allowed to stand overnight at 5°C to obtain jelly jelly Grass glue aqueous solution;

[0042] Preparation of ammonia alcohol solution:

[0043] Calculated by volume ratio, that is, the ratio of ammonia water: isopropanol is 1:1.5, and the mixture formed by mixing ammonia water and isopropanol is ammonia alcohol solution;

[0044] Wherein the ammoniacal liquor used is the ammoniacal solution that concentration is 3mol / L;

[0045] Used isopropanol is the isopropanol aqueous solution of 58% in mass percentage concentration;

[0046] (2), preparation of amidated jelly ...

Embodiment 2

[0064] The preparation method of above-mentioned a kind of amidated jelly gum, specifically comprises the steps:

[0065] (1) Preparation of solution

[0066] The preparation of jelly jelly gum aqueous solution:

[0067] Calculate the jelly gum that passed through the 60-mesh sieve by weight, that is, the ratio of jelly jelly gum to distilled water is 15:100, fully dissolve the jelly jelly gum in distilled water and let it stand at 5°C overnight to obtain the jelly jelly Grass glue aqueous solution;

[0068] Preparation of ammonia alcohol solution:

[0069] Calculated by volume ratio, that is, the ratio of ammonia water: isopropanol is 1:2, and the mixture formed by mixing ammonia water and isopropanol is the ammonia alcohol solution;

[0070] Wherein the ammoniacal liquor used is the ammoniacal solution that concentration is 4mol / L;

[0071] Used isopropanol is the isopropanol aqueous solution of 60% in mass percentage concentration;

[0072] (2), preparation of amidated...

Embodiment 3

[0085] A preparation method for amidated jelly gum, specifically comprising the steps of:

[0086] (1) Preparation of solution

[0087] The preparation of jelly jelly gum aqueous solution:

[0088] The jelly gum that passed through the 60-mesh sieve is calculated according to the weight ratio, that is, the ratio of jelly jelly gum to distilled water is 16:100, fully dissolve the jelly jelly gum in distilled water and stand overnight at 5°C to obtain the jelly jelly Grass glue aqueous solution;

[0089] Preparation of ammonia alcohol solution:

[0090] Calculated by volume ratio, that is, the ratio of ammonia water: isopropanol is 1:2.5, and the mixture formed by mixing ammonia water and isopropanol is ammonia alcohol solution;

[0091] Wherein the ammoniacal liquor used is the ammoniacal solution that concentration is 5mol / L;

[0092] Used isopropanol is the isopropanol aqueous solution of 62% in mass percentage concentration;

[0093] (2), preparation of amidated jelly g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com