Tooling clamp for processing insulating collar turning and method for processing same

A technology of tooling fixtures and insulating rings, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of signal transmission of the whole machine, inaccurate connection of belts, accumulated axial deviation, easy clamping of workpieces, etc. , to achieve the effect of improving the one-time pass rate, reducing out-of-roundness, and uniform and gentle force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

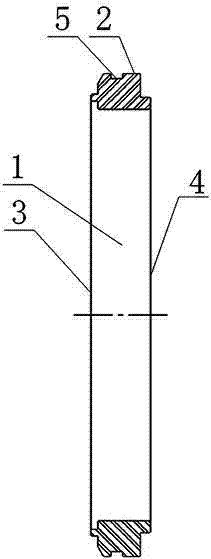

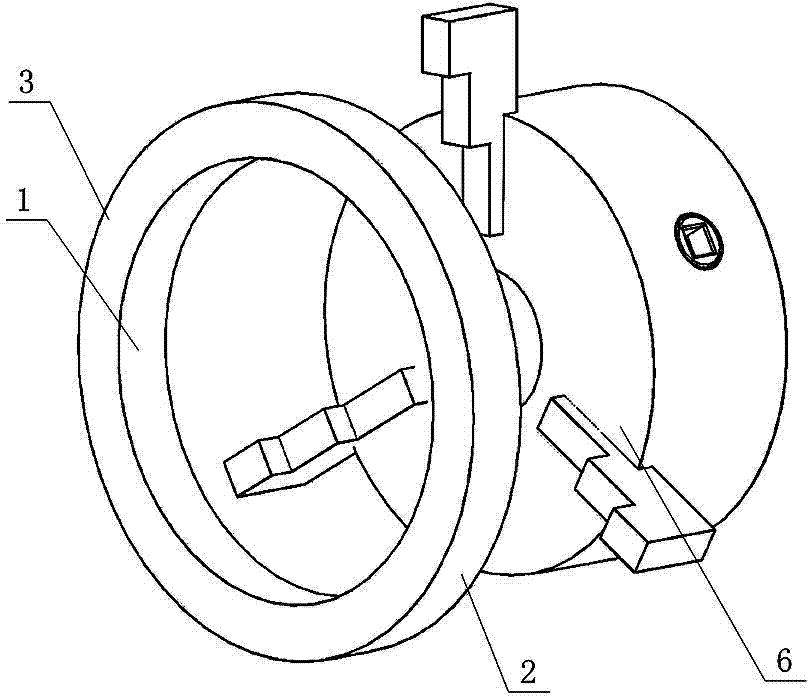

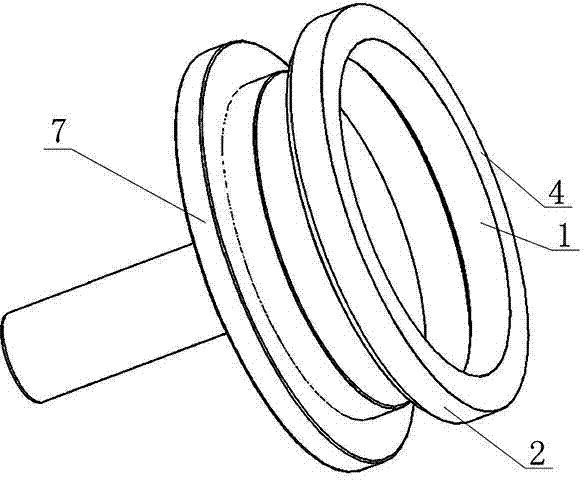

[0024] Insulating ring turning tooling fixture, it comprises concave surface fixture 8 and convex surface fixture 9, such as Figure 4 As shown, the concave fixture 8 includes a jaw chuck A10 and a plurality of equally shaped sector blocks A11 of the same shape, the number of the equally divided sector blocks A11 corresponds to the number of jaws 12 on the chuck A, The jaw chuck A10 in this embodiment is a three-jaw chuck, and the equally divided sector blocks A11 are respectively fixed on the corresponding jaws 12, and the equally divided sector blocks A11 are provided with fan-shaped depressions, and the sector-shaped depressions It is composed of fan-shaped plane A13 and arc-shaped side wall A14, such as Figure 4 As shown, the convex fixture 9 includes a jaw chuck B15 and a plurality of equally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com