Oil-in-water emulsion composition containing difluprednate and tobramycin

A technology of difluprednate and oil-in-water type, which is applied in the field of compositions containing difluprednate and tobramycin, which can solve the problems of storage stability without tobramycin and achieve storage stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

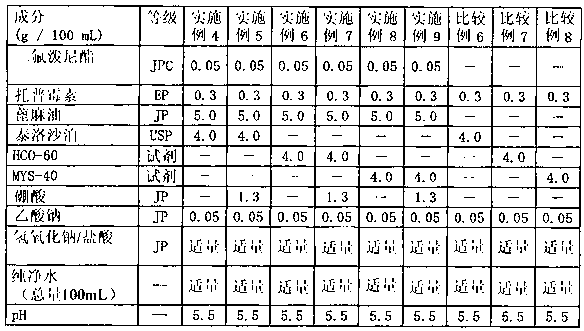

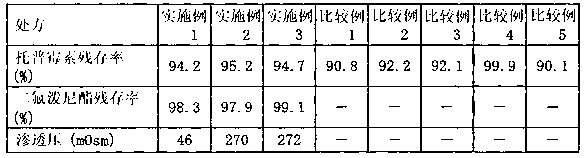

Method used

Image

Examples

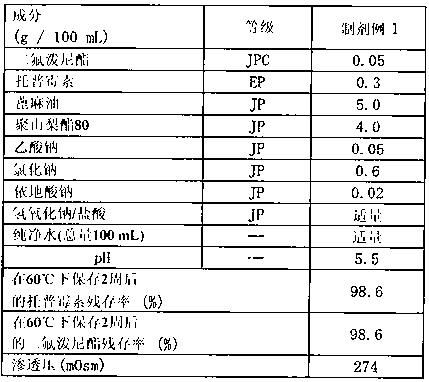

Embodiment 1

[0083] The preparation method of embodiment 1

[0084] 1) According to the above prescription, add and dissolve polysorbate 80 and sodium acetate in purified water.

[0085] 2) Add hydrochloric acid to adjust the pH to 5.4-5.6.

[0086] 3) Separately, difluprednate was added to castor oil (manufactured by NOF), and dissolved in a water bath (85 to 95° C.) (liquid A).

[0087] 4) Slowly add Liquid A to the liquid (65-75°C) in 2) to roughly emulsify it (mixer: Robo Mics, TOKUSHU KIKA KOGYO, rotation speed: about 8000 rpm, stirring time: 1 hour after adding Liquid A).

[0088] 5) Allow to cool to room temperature, and check the pH (pH 5.4 to 5.6).

[0089] 6) Add purified water and make the volume to 50% of the specified amount.

[0090] 7) Use a high-pressure emulsification machine (micro jet machine, Microfluidics Corporation) to process a pressure of about 1500 kgf / cm 2 1. The temperature of the sample cooling water bath is about 35-45°C, and the number of passes is 20 tim...

Embodiment 2

[0094] The preparation method of embodiment 2

[0095] 1) According to the above prescription, add and dissolve polysorbate 80, sodium acetate, sodium edetate, boric acid and tobramycin in purified water.

[0096] 2) Separately add difluprednate to castor oil, and dissolve in a water bath (85-95° C.) (liquid A).

[0097] 3) Slowly add Liquid A to the liquid (65-75°C) in 1) to roughly emulsify it (mixer: Robo Mics, TOKUSHU KIKA KOGYO, rotation speed: about 8000 rpm, stirring time: 1 hour after adding Liquid A).

[0098] 4) Allow to cool to room temperature, add hydrochloric acid, and adjust the pH to 5.4-5.6.

[0099] 5) Add purified water, set the volume to the specified amount, and check the pH (pH 5.4 to 5.6).

[0100] 6) Use a high-pressure emulsification machine (micro jet machine, Microfluidics Corporation) to process a pressure of about 1500 kgf / cm 2 1. The temperature of the sample cooling water bath is about 35-45°C, and the number of passes is 20 times to prepare t...

Embodiment 3

[0101] The preparation method of embodiment 3

[0102] 1) According to the above prescription, add and dissolve polysorbate 80, sodium acetate, sodium edetate and tobramycin in purified water.

[0103] 2) Add hydrochloric acid to adjust the pH to 5.4-5.6.

[0104] 3) Separately add difluprednate to castor oil, and dissolve in a water bath (85-95° C.) (liquid A).

[0105] 4) Slowly add Liquid A to the liquid (65-75°C) in 2) to roughly emulsify it (mixer: Robo Mics, TOKUSHU KIKA KOGYO, rotation speed: about 8000 rpm, stirring time: 1 hour after adding Liquid A).

[0106] 5) Allow to cool to room temperature, and check the pH (pH 5.4 to 5.6).

[0107] 6) Add purified water and make the volume to the specified amount.

[0108] 7) Use a high-pressure emulsification machine (micro jet machine, Microfluidics Corporation) to process a pressure of about 1500 kgf / cm 2 1. The temperature of the sample cooling water bath is about 35-45°C, and the number of passes is 20 times to prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com