Ultraviolet-cured resin composition and application thereof as solder resist

A technology for curing resins and compositions, applied in the field of solder resist, can solve the problems of customers' use troubles and narrow operating latitude, and achieve the effect of reducing the peeling phenomenon of paint film, small volume shrinkage and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

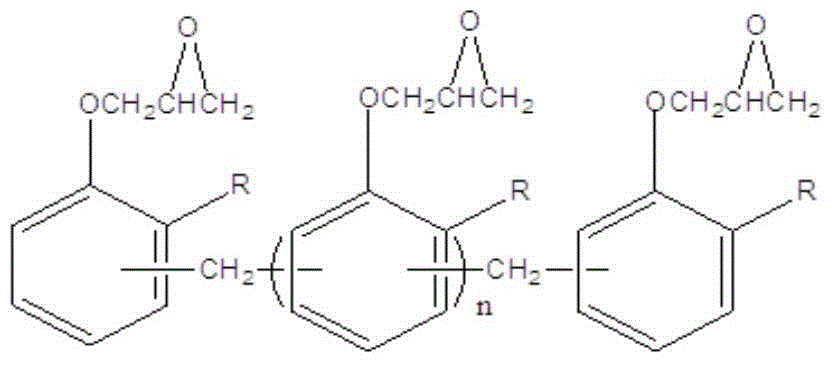

[0028] (1) Synthesis of novolac epoxy acrylate resin: 177 parts of novolac epoxy resin (manufactured by Changchun Artificial Resin, PNE-177) and 30 parts of trimethylolpropane triacrylate were heated to 80°C to dissolve, and then slowly dripped Add a mixture of 72 parts of acrylic acid, 0.38 parts of triphenylphosphine, and 0.12 parts of p-hydroxyanisole, and heat to 100°C for 7 hours to obtain a novolac epoxy acrylate resin;

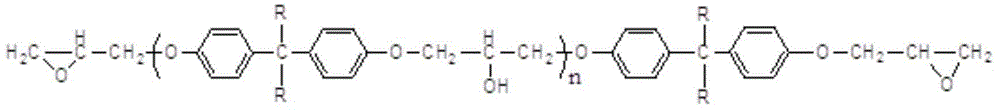

[0029] (2) Synthesis of bisphenol epoxy acrylate resin: 550 parts of bisphenol A epoxy resin (Guodu Chemical Industry, YD-020) and 120 parts of trimethylolpropane triacrylate are heated to 70 ° C to dissolve, and then slowly Add dropwise a mixture of 7.2 parts of acrylic acid, 2.5 parts of N,N-dimethylbenzylamine, and 0.2 parts of hydroquinone, and heat to 115°C for 7 hours to obtain a bisphenol epoxy acrylate resin;

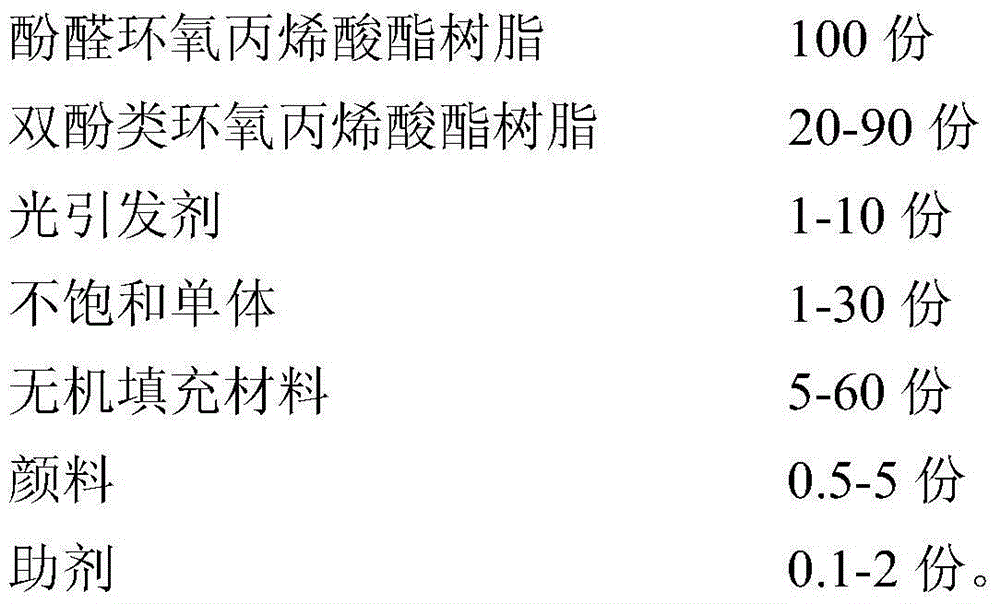

[0030] (3) Gained novolak epoxy acrylate resin, bisphenol epoxy acrylate resin and photoinitiator, unsaturated monomer, inorganic filler...

Embodiment 2

[0032](1) Synthesis of novolac epoxy acrylate resin: 177 parts of novolac epoxy resin (manufactured by Changchun Artificial Resin, PNE-177) and 30 parts of trimethylolpropane triacrylate, heated to 75 ° C to dissolve, and then slowly drop Add a mixture of 72 parts of acrylic acid, 0.38 parts of triphenylphosphine, and 0.12 parts of p-hydroxyanisole, and heat to 105 ° C for 6 hours to obtain novolac epoxy acrylate resin;

[0033] (2) Synthesis of bisphenol epoxy acrylate resin: 550 parts of bisphenol A epoxy resin (Guodu Chemical Industry, YD-020) and 120 parts of trimethylolpropane triacrylate are heated to 80 ° C to dissolve, and then slowly Add dropwise a mixture of 7.2 parts of acrylic acid, 2.5 parts of N,N-dimethylbenzylamine, and 0.2 parts of hydroquinone, and heat to 110°C for 5 hours to obtain a bisphenol epoxy acrylate resin;

[0034] (3) Gained novolak epoxy acrylate resin, bisphenol epoxy acrylate resin and photoinitiator, unsaturated monomer, inorganic filler mater...

Embodiment 3

[0036] (1) Synthesis of novolac epoxy acrylate resin: 177 parts of novolac epoxy resin (manufactured by Changchun Artificial Resin, PNE-177) and 30 parts of trimethylolpropane triacrylate were heated to 77°C to dissolve, and then slowly dripped Add a mixture of 72 parts of acrylic acid, 0.38 parts of triphenylphosphine, and 0.12 parts of p-hydroxyanisole, and heat it to 102 ° C for 8 hours to obtain a novolac epoxy acrylate resin;

[0037] (2) Synthesis of bisphenol epoxy acrylate resin: 550 parts of bisphenol A epoxy resin (Guodu Chemical Industry, YD-020) and 120 parts of trimethylolpropane triacrylate were heated to 75 ° C to dissolve, and then slowly Add dropwise a mixture of 7.2 parts of acrylic acid, 2.5 parts of N,N-dimethylbenzylamine, and 0.2 parts of hydroquinone, and heat to 112°C for 6 hours to obtain a bisphenol epoxy acrylate resin;

[0038] (3) Gained novolak epoxy acrylate resin, bisphenol epoxy acrylate resin and photoinitiator, unsaturated monomer, inorganic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com