Ginned cotton humidifying machine

A humidifier and lint technology, which is used in textiles and papermaking, fiber processing, packaging, etc., can solve the problems of reduced reliability of cotton processing equipment and lint humidification equipment, failure of lint humidification equipment, affecting the normal operation of equipment, etc. Maintain uptime and performance, high automation, high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

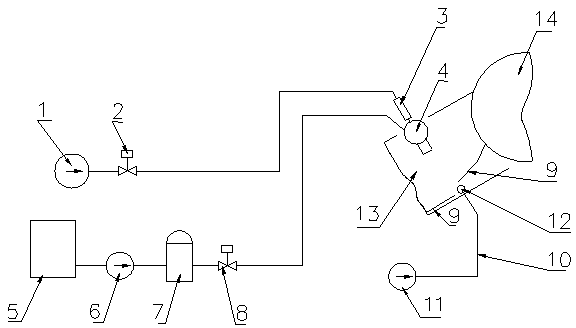

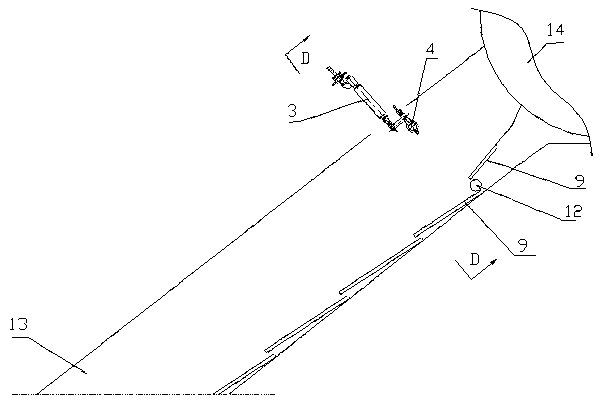

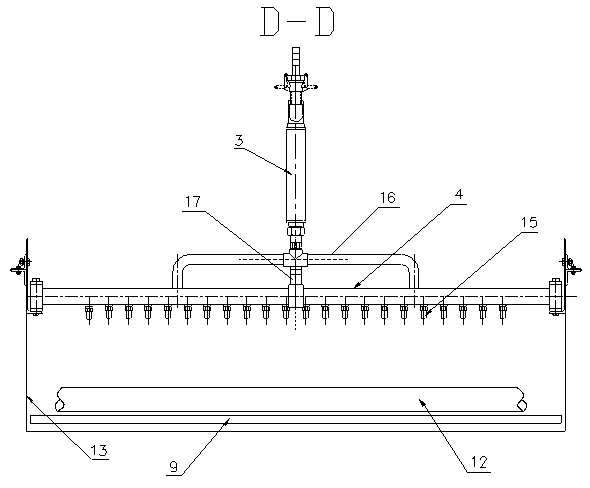

[0020] Such as figure 1 As shown in -7, the lint humidifier includes a water mist system, which is characterized in that: it also includes an auxiliary system, and the water mist system consists of an air compressor 1, a compressed air solenoid valve 2, a heater 3, a spray pipe 4, and an accumulator Water tank 5, water pump 6, filter 7 and solenoid valve 8 are made up, and described auxiliary system is made up of several pieces of slideway heating plate 9, blowing pipe 12, blower fan 11 and connecting pipeline 10; The pipe is connected to the air inlet of the compressed air solenoid valve 2, and the air outlet of the compressed air solenoid valve 2 is connected to the air inlet pipe of the heater 3 through the connecting pipe, and the air outlet pipe of the heater 3 is connected to the compressed air air inlet pipe 16 of the spray pipe 4. The water outlet of the water storage tank 5 is connected with the water inlet of the water pump 6 through the connecting pipe, the water ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com