Insertion-structure-based pilot-operated electric-hydraulic proportional spill valve

An electro-hydraulic proportional and pilot-operated technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the eccentricity of the center line of the pilot cone valve core and pilot valve sleeve, which affects the stability of hydraulic oil flow and damping Hole size can not be changed, etc., to improve the process, process formulation, processing and manufacturing convenience, and improve the effect of dynamic damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment this will be described in further detail.

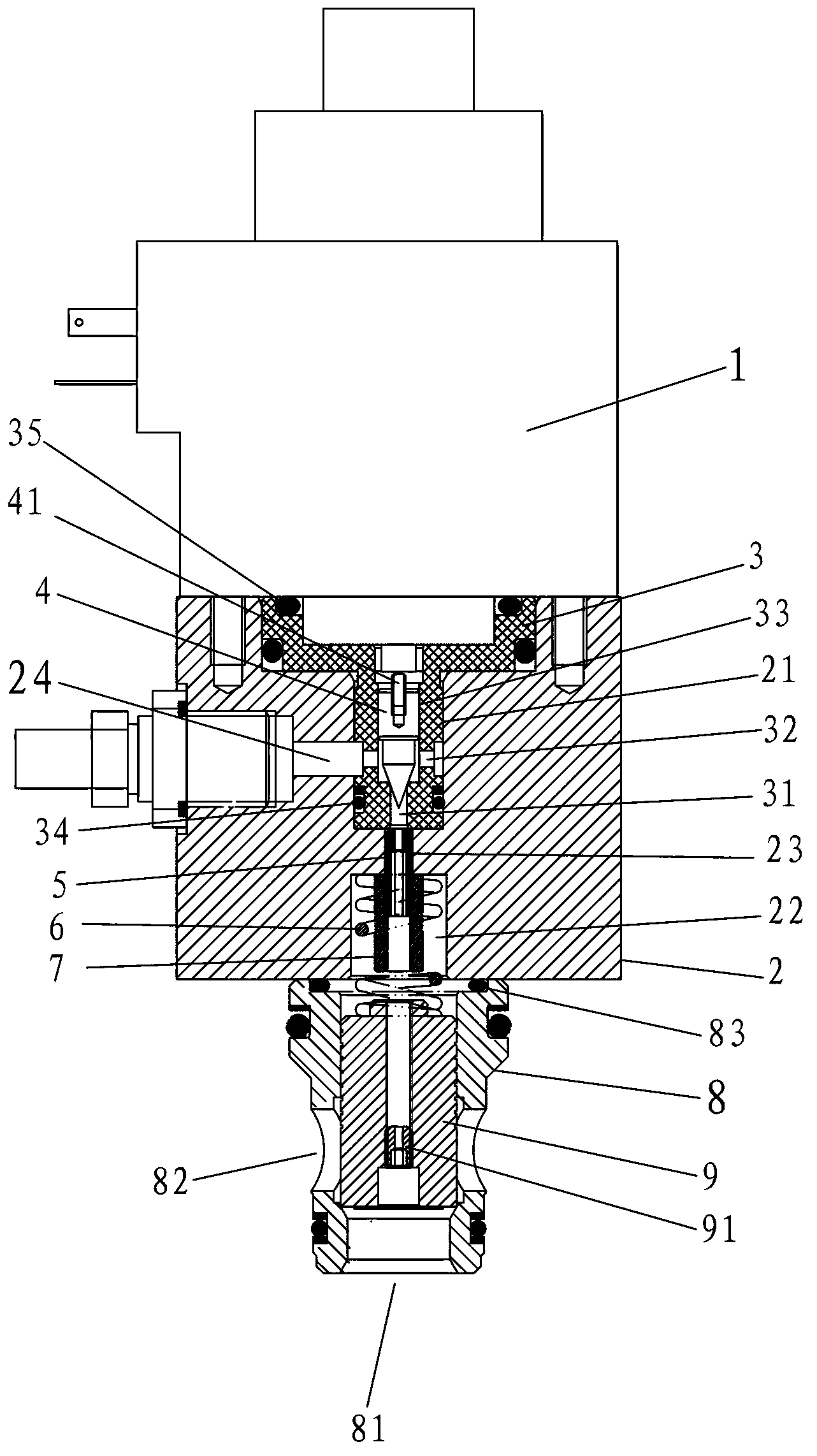

[0033] This case involves a pilot-operated electro-hydraulic proportional relief valve based on a cartridge structure, such as figure 1 As shown, it mainly includes the proportional electromagnet 1, the pilot valve body 2 and the main valve sleeve 8 arranged coaxially in sequence, and also includes the pilot valve sleeve 3, the pilot cone valve core 4, the first damper 5, the spring 6 and the main valve sleeve. Spool 9.

[0034] A first cavity 21 and a second cavity 22 are opened on both ends of the pilot valve body 2 in the axial direction, and a threaded hole 23 is formed between the first cavity 21 and the second cavity 22. The threaded hole 23 A first damper 5 is fitted inside, and an oil return port 24 is opened on the pilot valve body 2 , and the oil return port 24 is specifically extended in a radial direction and communicated with the first cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com