Hybrid transmission device for urban buses

An urban bus and hybrid technology, applied in the field of hybrid transmission, can solve the problems of large volume, weight and cost, and the difficulty of adjusting the transmission ratio range to meet the urban bus, so as to improve fuel economy and ride comfort. , the effect of reducing power and torque requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

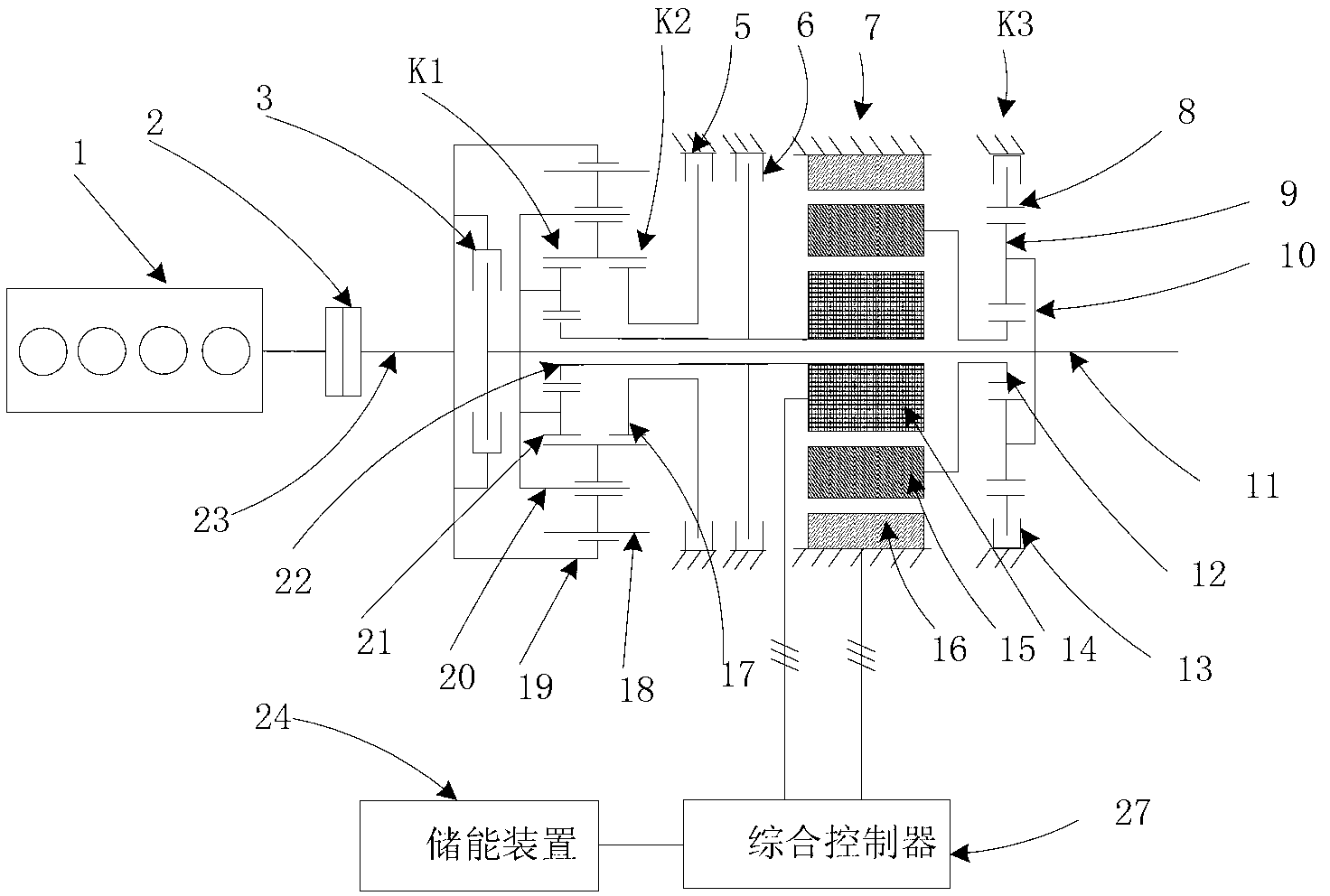

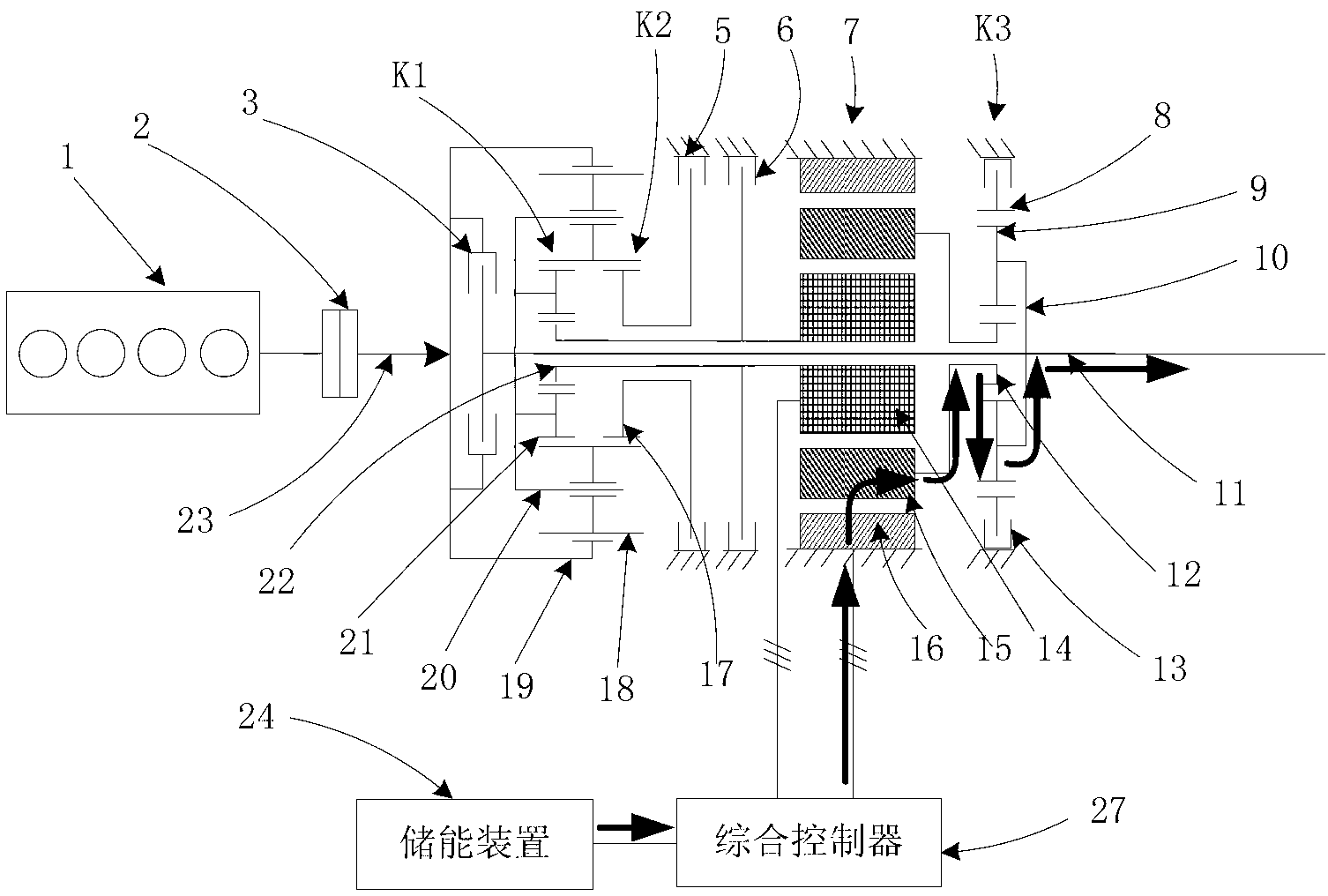

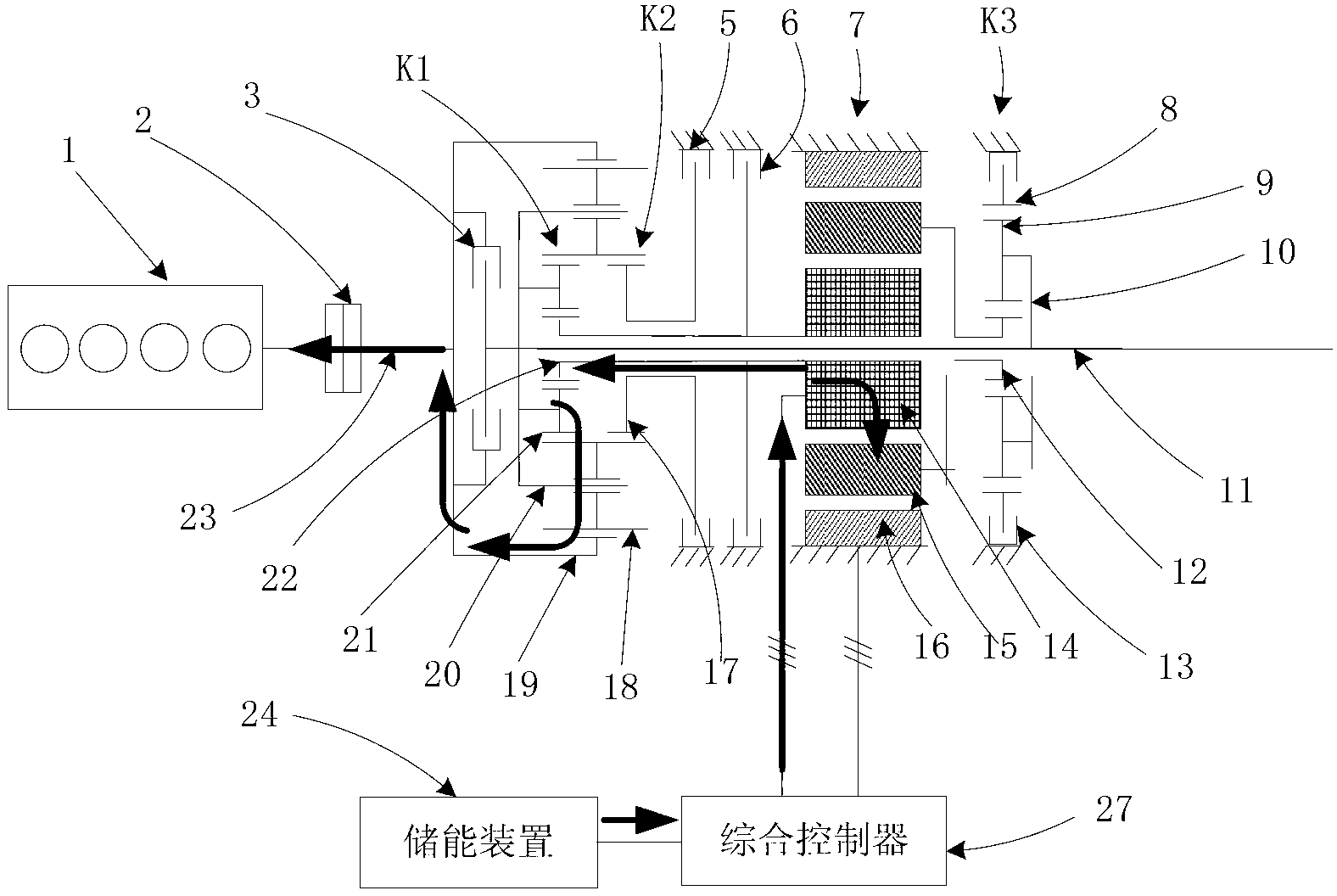

[0030] See attached figure 1 , one A hybrid power transmission device for an urban bus, which includes: an engine 1, a shaft coupling 2, a clutch 3, a power split bar, a power bus bar, a first brake 5, a second brake 6, a double-rotor motor 7, and a third brake 13. Output shaft 11, input shaft 23, energy storage device 24 and integrated controller 27;

[0031] The engine 1 is a diesel engine, which transmits power to the input shaft 23 through the coupling 2;

[0032] The power splitter includes: double-stage planetary gear mechanism K1, single-stage planetary gear mechanism K2, planet carrier A20 and ring gear 19, long planetary gear 18 and short planetary gear 21; double-stage planetary gear mechanism K1 and single-stage planetary gear mechanism K2 The planetary carrier A20 and the ring gear 19 are shared; the short planetary gear 21 and the long planetary gear 18 are installed on the planetary carrier A20, the short planetary gear 21 meshes with the sun gear A22 of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com